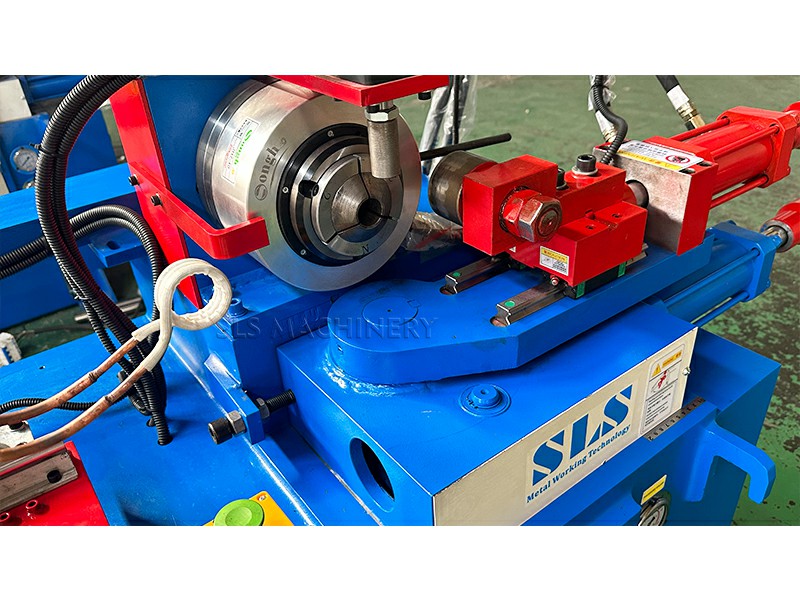

Pipe End Forming Machine

Metal tube end forming machines employ various processes including OD reducing, swaging, tube expanding, beading, taper forming, embossing & forging, flanging, end closing, and profile forming to achieve precision processing and functional enhancement of tube ends. Swaging creates tapered transitions through radial compression to improve assembly sealing; tube expanding ensures pressure-bearing strength through interference fits with tube sheets; beading forms flange structures via axial pressure to enhance connection reliability; taper forming enables precision guidance and sealed connections; embossing & forging increases surface anti-torsion capability; flanging expands welding area and provides sealing bases; end closing achieves complete tube end sealing; while profile forming meets specialized connection requirements. These technologies are widely applied in medical devices, heat exchange equipment, high-pressure systems, hydraulic valves, tools and equipment, container pipelines, furniture protection, and fitness equipment. SLS Machinery integrates advanced technologies such as servo control and high-frequency heating to provide customers with highly efficient, consistent customized forming solutions.

Video of Tube End Forming

What is a tube end forming machine? What are the different types and their respective uses?

A tube end forming machine is specialized equipment used for plastic processing of metal tube ends. It employs hydraulic or servo drives with precision molds to accurately reshape tube ends. Key processing types include: flaring for heat exchanger tube sheet connections and pipeline sealing; swaging to achieve tube interlocking assembly and fluid control; flanging that creates lip structures to enhance welding strength and accommodate seal installation; end closing for complete sealing of tube ends, suitable for furniture components and protective structures; upsetting that locally thickens tube ends for high-strength threading; knurling that creates anti-slip patterns on surfaces to improve grip; and profile forming which processes tube ends into special sections like square shapes to meet customized connection requirements. These technologies are widely applied in automotive manufacturing, home appliances, fitness equipment, and petrochemical industries, significantly enhancing product sealing performance, connection strength, and assembly efficiency through modifications to tube end configurations...

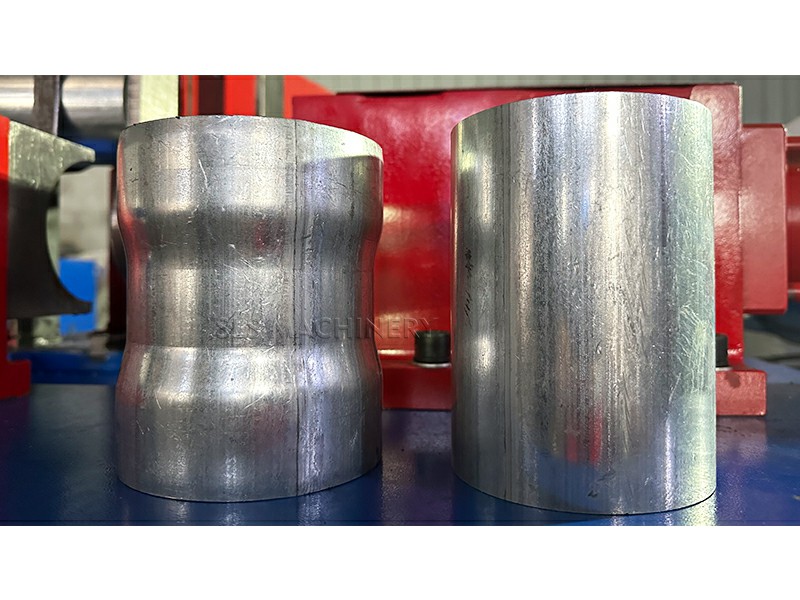

Tube Reducing Machine ( OD Shrinking Forming )

Tube end reducing machines employ radial cold extrusion technology, utilizing tapered molds to apply pressure on metal tube ends for plastic deformation and precise diameter contraction. This technology primarily serves tube interconnection assembly, fluid control optimization, and end-structure reinforcement, effectively enhancing connection sealing and assembly efficiency. Common applications include furniture leg finishing, automotive exhaust pipe forming, and fitness equipment weight rod processing, achieving functional requirements while ensuring aesthetic treatment and safety protection ...

Tube Expanding Machine

Tube expanding machines operate on the radial expansion principle, utilizing hydraulic or mechanical drives to radially expand a mandrel inside the tube end, forcing the tube wall to undergo plastic deformation and create an interference fit with the tube sheet. Its core function is to achieve tight connections between tubes and tube sheets, ensuring sealing integrity and tensile strength while enhancing heat transfer efficiency by eliminating gaps. This technology is primarily applied in the manufacturing of heat exchangers, boilers, condensers, and other pressure vessels, serving as a critical process equipment for tube-to-tube sheet connections in power ...

Rotary Tube Tapering Machine

Tube tapering machines utilize spinning or extrusion forming technology to apply directional pressure on metal tube ends through rollers or molds, causing plastic deformation to create precision tapered surfaces. This process not only achieves industrial functions such as sealed connections and fluid optimization, but also creates elegant tapered finishes for consumer products like furniture legs. The formed components combine structural strength with aesthetic value, finding extensive applications in industrial fields including hydraulic system ports and aerospace pipeline connectors, as well as civilian products such as modern furniture legs and decorative columns ...

Tube End Sealing Machine / Pipe Flanging Machine

Tube end closing machines and tube flanging machines are two critical types of tube end forming equipment. The closing machine utilizes spinning or stamping technology to plastically deform the tube end, achieving complete closure and forming hemispherical or other end structures. It is primarily used in applications requiring sealing and safety protection, such as furniture legs and fitness equipment weight rods. The flanging machine employs a mandrel expansion process to form an annular lip on the tube end, enhancing connection strength by increasing the welding area and providing a mounting base for sealing elements. It is widely applied in scenarios demanding high-strength connections, such as automotive fuel lines and pressure vessel pipelines ...

Choose A Suitable Pipe End Forming Machine for You

Max. diameter Ø 4.5" (115 mm)

Max. wall thickness 4mm

Function: pipe end forming

Forming Station No.: 1-2-3-4-5-6

Max. diameter Ø 2" (50 mm)

Max. wall thickness 2.5mm

Function: pipe end beading

One-step molding of mold extrusion

Max. diameter Ø 2" (50 mm)

Max. wall thickness 2.0mm

Function: pipe taper forming

Automatic loading & Fixed length feeding

Contact Us

SLS - Recommended Products

Pipe End Forming Applications

FAQs

1.Q: What specific types of tube end forming can this machine perform?

2.Q: Is this machine suitable for my tube material and size?

3.Q: How does it ensure accuracy (e.g., diameter, roundness) and surface finish?

4.Q: How complex and time-consuming is mold changeover for different tubes or shapes?

5.Q: Do I need to purchase separate molds for each tube size and shape?

The Purpose of Pipe End Forming Machine

-

![Tube End Forming And Sealing Machines: A Comprehensive Guide From Principles To Applications Tube End Forming And Sealing Machines: A Comprehensive Guide From Principles To Applications]() The Core Principle Of Tube End Sealing Machines Is To Precisely Seal The Ends Of Metal Tubes Through High-Frequency Induction Heating And Spinning Forming Technology. Tube End Forming And Sealing Machines Are Highly Efficient And Precise Equipment Widely Used In Boiler Drums, Automotive Exhaust Systems, Furniture Manufacturing, Building Railings, Medical Devices, And More...

The Core Principle Of Tube End Sealing Machines Is To Precisely Seal The Ends Of Metal Tubes Through High-Frequency Induction Heating And Spinning Forming Technology. Tube End Forming And Sealing Machines Are Highly Efficient And Precise Equipment Widely Used In Boiler Drums, Automotive Exhaust Systems, Furniture Manufacturing, Building Railings, Medical Devices, And More... -

![Applications Of CNC Metal Pipe End Forming Machines In The Furniture And Automotive Industries Applications Of CNC Metal Pipe End Forming Machines In The Furniture And Automotive Industries]() CNC Metal Pipe End Forming Machines Control The Shape And Size Of Metal Pipe Ends Through A CNC System, Using Processes Such As Flaring, Reducing, And Bending. These Processes Ensure Precise Control Over The Shape And Dimensions Of Pipe Ends, Resulting In Structurally Stable And Reliable Products...

CNC Metal Pipe End Forming Machines Control The Shape And Size Of Metal Pipe Ends Through A CNC System, Using Processes Such As Flaring, Reducing, And Bending. These Processes Ensure Precise Control Over The Shape And Dimensions Of Pipe Ends, Resulting In Structurally Stable And Reliable Products... -

![Tube End Forming Machines: From Principles To Applications, Unlocking The Secrets Of Efficient Tube Processing Tube End Forming Machines: From Principles To Applications, Unlocking The Secrets Of Efficient Tube Processing]() Tube End Forming Machines, As Efficient And Precise Processing Equipment, Have Become An Indispensable Tool In Manufacturing. Suzhou SLS Machinery Co., Ltd. (SLS MACHINERY), A Leading Manufacturer Of Tube Processing Equipment, Is Committed To Providing Innovative Tube End Forming Solutions To Help Businesses Achieve Efficient Production And Growth...

Tube End Forming Machines, As Efficient And Precise Processing Equipment, Have Become An Indispensable Tool In Manufacturing. Suzhou SLS Machinery Co., Ltd. (SLS MACHINERY), A Leading Manufacturer Of Tube Processing Equipment, Is Committed To Providing Innovative Tube End Forming Solutions To Help Businesses Achieve Efficient Production And Growth...

Keep In Touch With Us

SLS Machinery, as a professional manufacturer of tube processing equipment, offers a comprehensive range of products including CNC tube bending machines, precision cold saw cutting machines, and multi-function tube end forming machines. We are committed to providing complete tube processing solutions for various industries. We cordially invite you to collaborate with us to access professional equipment selection advice and complimentary sample processing services, working together to enhance production efficiency...

Mob:+86-181 0015 0701 ( Whatsapp / Wechat - Same Number )

English

English