Cold Saw Cutting Solutions: High-Precision Pipe & Tube Cutting Machines

When it comes to high-precision metal cutting, nothing matches the efficiency of a Cold Saw Machine. Also known as a Cold Sawing Machine or Circular Cold Saw, this tube cutting machine and pipe cutting machine utilizes high-speed steel (HSS) blades to deliver unparalleled cut quality. The result is smooth, burr-free edges with no heat-affected zone, making it the ideal steel pipe cutter and aluminum cutting saw.

Whether you need a Manual Cold Saw for flexibility with small batches, a Semi-Automatic Cold Saw for consistent medium-volume output, or a fully Automatic Cold Saw and CNC Cold Saw for large-scale, unmanned production, there is a cold saw cutting system to match your needs. This industrial cold saw is exceptionally well-suited for processing materials with extreme quality demands, including stainless steel tubes, aluminum alloy tubes, and other thin-walled materials, as well as round, square, and special-shaped profiles. It effectively prevents material deformation and eliminates the need for secondary processing.

Achieving this precision cold saw performance requires core technological expertise and the assurance of an excellent brand. As a leading cold saw manufacturer, SLS Machinery is an expert in providing complete cold saw cutting solutions. We help you find the best cold saw machine—from a robust metal bar cutting saw to a high-throughput automatic pipe cutting machine—that delivers efficiency, precision, and reliability.

Looking for a Cold Saw Machine for Sale? Let SLS help you transform the fundamental process of material cutting into a core competitive advantage for your products.

Video of Tube Saw Cutting

What Are The Best Pipe Cutting Machines & Types, Advantages and Features?

The core of a good pipe cutting machine lies in achieving high-quality cuts that require no secondary processing through high precision, high efficiency, and high cost-effectiveness. Manual models excel in flexibility and low cost, making them ideal for small-batch customization and maintenance scenarios. Semi-automatic models, which automate the cutting process while retaining manual loading, offer an optimal balance of accuracy and affordability, serving as the perfect choice for small to medium-volume continuous production. Fully automatic models deliver maximum efficiency and minimal labor costs through unmanned operation, specifically designed for large-scale standardized production. Selecting the right type ultimately depends on aligning the machine with your specific production scale and efficiency requirements.

Manual Pipe Cutting Machine ( Circular saw Machine )

A manual pipe cutting machine (also known as a circular pipe saw) is a basic equipment for cutting metal pipes through manual operation. Its core value lies in excellent flexibility and cost-effectiveness. It can quickly adapt to small-batch cutting tasks of various specifications, with simple operation and low costs. Although its efficiency is limited by reliance on manual operation, it offers irreplaceable advantages in scenarios such as maintenance workshops, small-scale processing, and prototype development.

Semi-auto Tube Cutting Machine

A semi-automatic pipe cutting machine, which operates through manual loading and an automatic cutting cycle, significantly enhances cutting accuracy and production efficiency while maintaining operational flexibility. Its core advantage lies in achieving the optimal balance between cost and performance, enabling it to meet the standardized demands of small-to-medium batch continuous production while effectively reducing labor costs and intensity. It serves as an ideal transitional and primary solution for processing enterprises moving from manual operations toward scaled production.

Multi-head Automatic Pipe Cutting Machine

A multi-head pipe cutting machine achieves simultaneous multi-segment cutting of a single pipe by integrating multiple sawing units, with its core value lying in the multiplication of production efficiency. While ensuring extremely high cutting accuracy, this equipment can significantly reduce material waste. It is suitable for industries requiring mass production of standardized pipe components, such as automotive exhaust systems and furniture frames, serving as the ultimate high-efficiency solution for large-scale automated manufacturing in major enterprises.

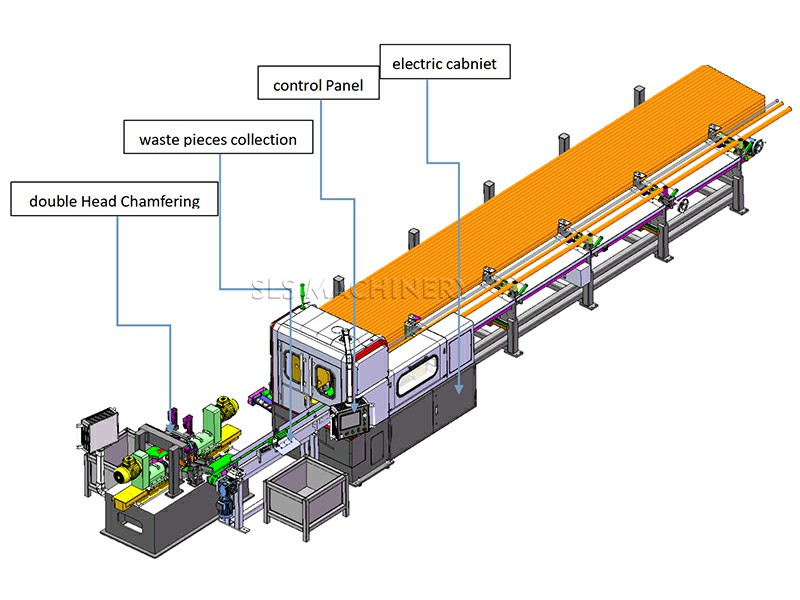

Fully Automatic Pipe Cutting Machine ( Automated Production Line)

A fully automatic pipe cutting production line is a complete solution that integrates feeding, cutting, chamfering, pipe reducing, and other processes to achieve full automation of the pipe processing workflow. Its core value lies in the perfect combination of maximizing production efficiency and minimizing labor costs. By eliminating clamping errors and waiting times between intermediate steps, the production line ensures extremely high precision consistency and quality stability. It is particularly suitable for large-scale, high-standard continuous production needs in fields such as automotive manufacturing and high-end home appliances, serving as the core equipment for achieving ultimate efficiency in pipe processing within modern smart factories.

Choose A Suitable Pipe Cutting Machine for You

Max. diameter Ø 2.5" (85 mm)

Max. wall thickness 2.5mm

Manual angle adjustment

Manual feeding with optional positioner

Max. diameter Ø 5" (125 mm)

Max. wall thickness 4.0mm

Cutting of various pipes and rods

Automatic feeding and angle adjustment

Max. diameter Ø 4" (102 mm)

Max. wall thickness 3.0mm

Cutting length adjustment

Automatic loading and multi-section cutting

Contact Us

SLS - Recommended Products

Cold Saw - Tube Cutting Applications

FAQs

1.Q: What is the main advantage of cold saw cutting?

2.Q: What materials and size ranges can it handle?

3.Q: How precise is the cut, and what is the cut quality?

4.Q: What are the automation options? Can it be integrated into a production line?

5.Q: What are the ongoing operation and maintenance costs?

The Purpose of Pipe Cutting Machine

-

![From Standard To Precision Tube Cutting: Worm Gear, All-Gear & Cold Saw Technologies Compared | SLS Manufacturing From Standard To Precision Tube Cutting: Worm Gear, All-Gear & Cold Saw Technologies Compared | SLS Manufacturing]() High-Speed Steel (HSS) Fully Automatic Pipe Cutting Machines Have Become Indispensable Equipment In Modern Manufacturing Due To Their Efficiency, Precision, And Automation. These Machines, Which Use HSS Blades To Cut Metal Pipes Such As Steel, Copper, And Aluminum, Are Widely Used Across Various Industries...

High-Speed Steel (HSS) Fully Automatic Pipe Cutting Machines Have Become Indispensable Equipment In Modern Manufacturing Due To Their Efficiency, Precision, And Automation. These Machines, Which Use HSS Blades To Cut Metal Pipes Such As Steel, Copper, And Aluminum, Are Widely Used Across Various Industries... -

![CNC Automatic Aluminum Cutting Saw: The Smart Tool for Modern Industrial Aluminum Processing CNC Automatic Aluminum Cutting Saw: The Smart Tool for Modern Industrial Aluminum Processing]() In The Construction Industry, CNC Automatic Aluminum Cutting Saws Are Widely Used For Cutting Aluminum Profiles For Doors And Windows. A Construction Company Using This Equipment Not Only Improved Cutting Precision And Production Efficiency But Also Reduced Material Waste And Significantly Shortened Project Timelines...

In The Construction Industry, CNC Automatic Aluminum Cutting Saws Are Widely Used For Cutting Aluminum Profiles For Doors And Windows. A Construction Company Using This Equipment Not Only Improved Cutting Precision And Production Efficiency But Also Reduced Material Waste And Significantly Shortened Project Timelines... -

![The Wide Application Of HSS Fully Automatic Pipe Cutting Machines In Daily Use The Wide Application Of HSS Fully Automatic Pipe Cutting Machines In Daily Use]() High-Speed Steel (HSS) Fully Automatic Pipe Cutting Machines Have Become Indispensable Equipment In Modern Manufacturing Due To Their Efficiency, Precision, And Automation. These Machines, Which Use HSS Blades To Cut Metal Pipes Such As Steel, Copper, And Aluminum, Are Widely Used Across Various Industries...

High-Speed Steel (HSS) Fully Automatic Pipe Cutting Machines Have Become Indispensable Equipment In Modern Manufacturing Due To Their Efficiency, Precision, And Automation. These Machines, Which Use HSS Blades To Cut Metal Pipes Such As Steel, Copper, And Aluminum, Are Widely Used Across Various Industries...

Keep In Touch With Us

SLS Machinery, as a professional manufacturer of tube processing equipment, offers a comprehensive range of products including CNC tube bending machines, precision cold saw cutting machines, and multi-function tube end forming machines. We are committed to providing complete tube processing solutions for various industries. We cordially invite you to collaborate with us to access professional equipment selection advice and complimentary sample processing services, working together to enhance production efficiency...

Mob:+86-181 0015 0701 ( Whatsapp / Wechat - Same Number )

English

English