+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Our Condenser Heat Exchanger Copper Tube End Forming Machine | SS Aluminum Tubular Pipe Reducing Equipment -TM 25NC. Condenser / Heat Exchanger Tubes Are Core Components Required For Efficient Heat Transfer Applications, And SLS Machinery Tube End Forming Machines Are A Leading Manufacturing And Processing Equipment. Our Equipment Is Widely Used Across Various Industries, Including Home Appliances, HVAC And Heating Equipment, Commercial Equipment, Industrial Equipment, And The Automotive Industry. Our Specialized Manufacturing Capabilities And Extensive Experience Distinguish Us In Industries That Prioritize Precision And Performance. (High Precision, Superior Materials, Innovative Designs, And High-Volume Production.) Whether You Need A Custom Machine For Specific Production Needs Or A High-Volume Production Solution, SLS Can Deliver Safe, Reliable, And Durable Equipment In The Shortest Possible Time. Choosing SLS Means Choosing Success. Contact Us Today And Let Us Help You Realize Your Project Needs!

_________________________________________________________________________

Model: TM-25NC

Specification: 25mm(1")x1.5mm

Drive Mode: Mechanical & Hydraulic

Technical: Press( Tube End Forming )

Business Type: Professoinal Manufacturer

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 35 Days Dated From Deposit Received

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

Condenser Heat Exchanger Copper Tube End Forming Machine | SS Aluminum Tubular Pipe Reducing Equipment - TM-25NC

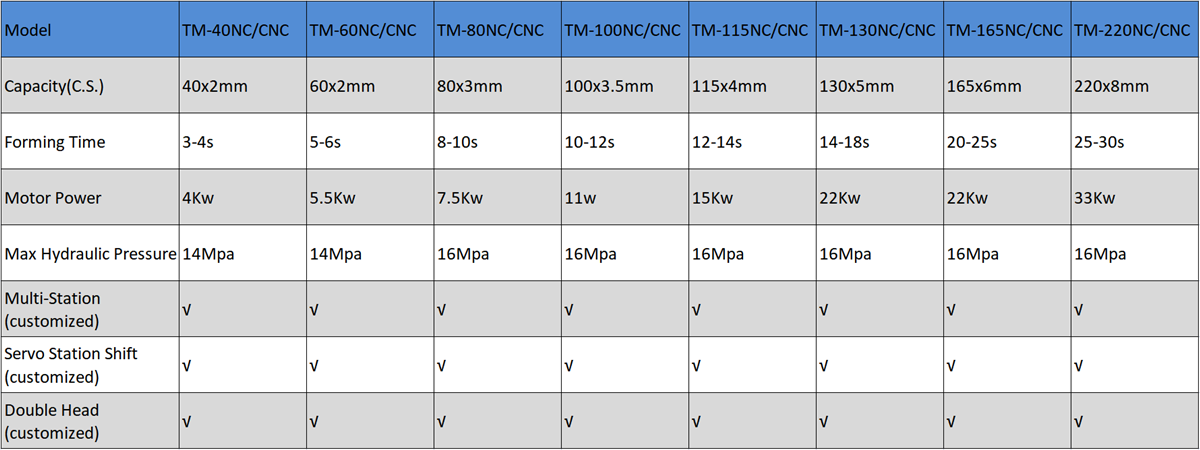

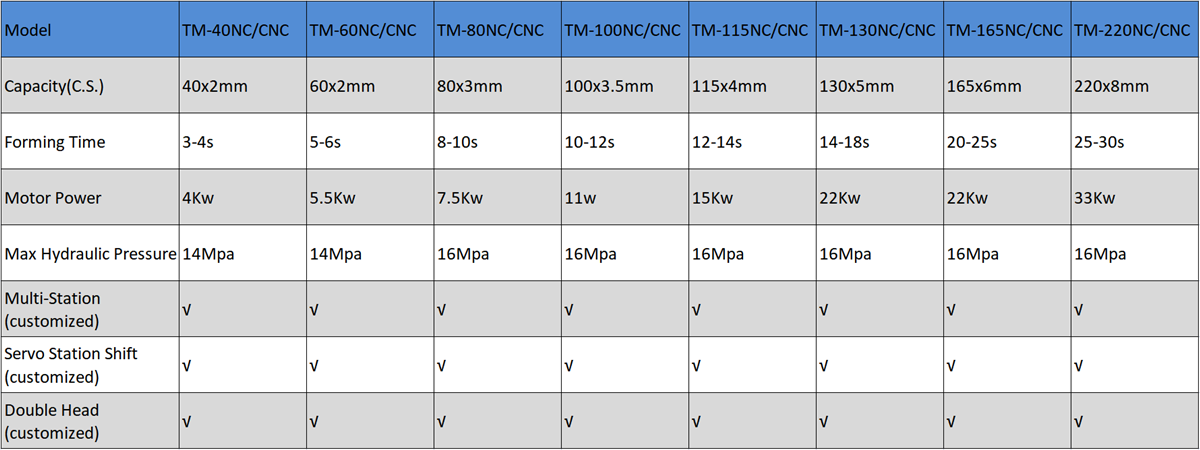

Main Technical Parameters Sheet

Brief Introduction on Condenser Heat Exchanger Copper Tube End Forming Machine

SLS Machinery Tube Benders And End Formers Are Essential Processing Equipment For The Production Of Electrical Heating Elements And Components. Our Equipment Is Used In A Wide Range Of Industries:

* Home Appliances: Includes Kitchen Appliances (Microwaves, Ovens, Dishwashers, Coffee Makers, Refrigerators, Water Dispensers, Stoves), Laundry Care Equipment (Washing Machines, Dryers), And Bathroom Appliances (Water Heaters, Smart Toilets).

* HVAC And Heating Equipment: Examples Include Air Conditioners, Heaters, And Heat Pumps.

* Commercial Equipment: Includes Kitchen Equipment, Cleaning Equipment, And Beverage Dispensers (Vending Machines, Coffee Machines).

* Industrial Equipment: Supports Rubber And Plastics Engineering, Medical And Diagnostic Equipment, Specialized Equipment, Semiconductors, And Energy Systems.

* Automotive: Essential Equipment For The Production Of Heating Elements And Related Components.

At SLS Machinery, We Have Extensive Experience In Heater Tube Bending And Are Committed To Continuously Improving Our Manufacturing Capabilities And Equipment Performance. Whether You Need A Custom Machine Tailored To Your Specific Production Needs Or A High-Volume Production Solution, SLS Machinery Can Deliver Safe, Reliable, And Durable Equipment In The Shortest Possible Time. Let Us Help You Realize Your Project—Contact Us Today To Explore How We Can Meet Your Unique Needs!

Features on Condenser Heat Exchanger Copper Tube End Forming Machine

● Touch Screen or Human Interface Offers Easy Access to Auto and Manual Operating Modes.

● Equipped with Emergency Stop Device.

● Suitable for The Shrinking for Various Metal Pipes with Different Material and Different Shape.

● All The Parts Are Made Under Very Strict Quality Control, So The Quality of Machine Is In High Level and The Specification Is Standardized.

● Both Manual and Automatic Operations Are Available.

● Tube Clamping and End Forming Driven by Hydraulic.

● Forming Shapes Can Be Convex, Concave, Sectional, Long & Flat, Square, V-Shape, Open Elbow, Flat Elbow...Etc.

● The Design of The Tooling Varies with Work-Piece & Customers Requirements.

● The Design of The Tooling Help Customer Easy to Change.

● Water or Fan Cooling System Ensures The Equipment Long-Time Work Stably Under The High Temperature.

● Foot Pedal Cycle Start.

● Optional:An Additional Feeding System Can Be Added to The Machine. The Operating Security Is Greatly Increased Because The Operators Just Do The Unloading & Collecting Job of Finished Pipes.

● Optional:Multi Station Can Be Added to The Machine Based on Detailed Forming Requirement.

● Optional: Double Head Can Be Added to The Machine Based on Detailed Forming Requirement.

● Optional: Multi Station Shifting Can Be Chosen As Servo(Electrical) or Hydraulic Control.

Main Application

Packaging & Shipping

Contact Us

Condenser Heat Exchanger Copper Tube End Forming Machine | SS Aluminum Tubular Pipe Reducing Equipment - TM-25NC

Main Technical Parameters Sheet

Brief Introduction on Condenser Heat Exchanger Copper Tube End Forming Machine

SLS Machinery Tube Benders And End Formers Are Essential Processing Equipment For The Production Of Electrical Heating Elements And Components. Our Equipment Is Used In A Wide Range Of Industries:

* Home Appliances: Includes Kitchen Appliances (Microwaves, Ovens, Dishwashers, Coffee Makers, Refrigerators, Water Dispensers, Stoves), Laundry Care Equipment (Washing Machines, Dryers), And Bathroom Appliances (Water Heaters, Smart Toilets).

* HVAC And Heating Equipment: Examples Include Air Conditioners, Heaters, And Heat Pumps.

* Commercial Equipment: Includes Kitchen Equipment, Cleaning Equipment, And Beverage Dispensers (Vending Machines, Coffee Machines).

* Industrial Equipment: Supports Rubber And Plastics Engineering, Medical And Diagnostic Equipment, Specialized Equipment, Semiconductors, And Energy Systems.

* Automotive: Essential Equipment For The Production Of Heating Elements And Related Components.

At SLS Machinery, We Have Extensive Experience In Heater Tube Bending And Are Committed To Continuously Improving Our Manufacturing Capabilities And Equipment Performance. Whether You Need A Custom Machine Tailored To Your Specific Production Needs Or A High-Volume Production Solution, SLS Machinery Can Deliver Safe, Reliable, And Durable Equipment In The Shortest Possible Time. Let Us Help You Realize Your Project—Contact Us Today To Explore How We Can Meet Your Unique Needs!

Features on Condenser Heat Exchanger Copper Tube End Forming Machine

● Touch Screen or Human Interface Offers Easy Access to Auto and Manual Operating Modes.

● Equipped with Emergency Stop Device.

● Suitable for The Shrinking for Various Metal Pipes with Different Material and Different Shape.

● All The Parts Are Made Under Very Strict Quality Control, So The Quality of Machine Is In High Level and The Specification Is Standardized.

● Both Manual and Automatic Operations Are Available.

● Tube Clamping and End Forming Driven by Hydraulic.

● Forming Shapes Can Be Convex, Concave, Sectional, Long & Flat, Square, V-Shape, Open Elbow, Flat Elbow...Etc.

● The Design of The Tooling Varies with Work-Piece & Customers Requirements.

● The Design of The Tooling Help Customer Easy to Change.

● Water or Fan Cooling System Ensures The Equipment Long-Time Work Stably Under The High Temperature.

● Foot Pedal Cycle Start.

● Optional:An Additional Feeding System Can Be Added to The Machine. The Operating Security Is Greatly Increased Because The Operators Just Do The Unloading & Collecting Job of Finished Pipes.

● Optional:Multi Station Can Be Added to The Machine Based on Detailed Forming Requirement.

● Optional: Double Head Can Be Added to The Machine Based on Detailed Forming Requirement.

● Optional: Multi Station Shifting Can Be Chosen As Servo(Electrical) or Hydraulic Control.

Main Application

Packaging & Shipping

Contact Us