+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Our Precision CNC Pipe Cutting And Chamfering Machine Is A Complete Automated Production Line Designed To Revolutionize The Pipe Cutting Process With Greater Accuracy, Speed And Versatility. The CNC Pipe Cutting Machine Can Not Only Achieve Efficient Cutting Of Pipes Made Of Various Metal Materials, But Can Also Customize Various Auxiliary Functions, Such As Pipe Chamfering And End Forming. (Expansion, Shrinkage, Sealing, Taper, Bending, Etc.) CNC Pipe Cutting Machines Are Widely Used In Various Industries Including Manufacturing, Construction, Automotive, Aerospace And Many Industries That Require Precise Pipe Cutting And Are Considered A Key Component Of Production And Assembly.

_________________________________________________________________________

Model: MC-400CNC (New Type)

Specification: Cut OD Form 20 to 80mm, 3-10mm (wall thickness).

Drive Mode: Electric + Hydraulic

Technical: Cold Saw Cutting + Servo Chamfering

Business Type: Professoinal Manufacturer

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 55 Days Dated From Deposit Received

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

SLS’s Efficiency Precision CNC Automatic Pipe Cutting And Chamfering Machine | The Complete Production Line Of Tube Cut Off Solutions

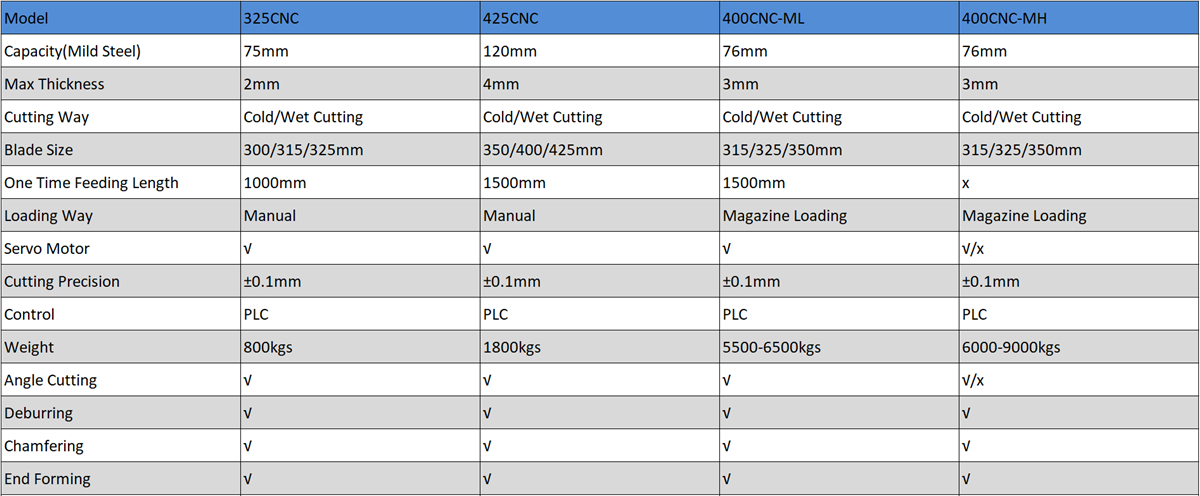

Main Technical Parameters Sheet

Brief Introduction on Precision CNC Automatic Pipe Cutting And Chamfering Machine

SLS’s Efficiency Precision CNC Automatic Pipe Cutting And Chamfering Machine | The Complete Production Line Of Tube Cut Off Solutions. Machine with Function of Pneumatic/Hydraulic Clamp, Servo Motor Feeding and Pneumatic/Hydraulic Cutting. Automatic Feeding Ensure High Cutting Accuracy and Increase Productivity. Good Mechanical System Ensures High Cutting Quality Without Burrs on Tube Internal and External. Water Cooling and Lubricate System Prolongs The Life of Machine and Saw Blade. Each Cold Saw Is Covered by One Year Parts Warranty Plus Lifetime Technical Support by SLS. We Keep Many Cold Saw Models In Stock for Quick Shipments.

Our Precision CNC Pipe Cutting And Chamfering Machine Is A Complete Automated Production Line Designed To Revolutionize The Pipe Cutting Process With Greater Accuracy, Speed And Versatility. The CNC Pipe Cutting Machine Can Not Only Achieve Efficient Cutting Of Pipes Made Of Various Metal Materials, But Can Also Customize Various Auxiliary Functions, Such As Pipe Chamfering And End Forming. (Expansion, Shrinkage, Sealing, Taper, Bending, Etc.) CNC Pipe Cutting Machines Are Widely Used In Various Industries Including Manufacturing, Construction, Automotive, Aerospace And Many Industries That Require Precise Pipe Cutting And Are Considered A Key Component Of Production And Assembly.

Features on Precision CNC Automatic Pipe Cutting And Chamfering Machine

● Adjustable Cutting Length Which Can Be Set on Touch Screen.

● Interactive PLC and Touch Screen Controlling Offers Easy Access to Auto And Manual Operating Modes.

● Automatic Servo Motor Feeding, Automatic Hydraulic Clamping and Automatic Hydraulic Cutting.

● Rigid Cast Iron Saw Bases and Electro-Welded Steel Frames Maintain Accuracy and Minimize Vibrations, Even At Full Capacity.

● Material of Tube Cutting Machine is Available:Steel&Stainless Steel.

● Cutting Shape Available: Round,Square,Rectangle and Other Profiles.

● Available for Several Pieces Cutting Together for Small Pipe Size.

● Clamping, Saw Blade Advancing and Backward, Clamp Releasing Are All Hydraulic Driven.

● 2 Sides and 2 Way Clamping System: High Precision Cutting, Reduce Vibration and Soundless While Cutting.

● Full Gear Machine Head Guarantee The Rigid And Stable Cutting Working Specially for Thick Tube Cutting.

● Good Cutting Quality for Tube Internal and External without Burs.

● Small Noisy

● Water Cooling and Lubricate System Prolongs The Life of Machine and Saw Blade.

● Good Mechanical Parts Ensure Machine Runs In High Stability.

● Optional:Feeding Rack for Cutting Pieces

● Optional:Customized Clamp Tool

● Optional: Angle Cutting

● Optional: Connect with Chamfering Machine

● Optional: Connect with Pipe Forming Machine

● Optional: Connect with Deburring Machine

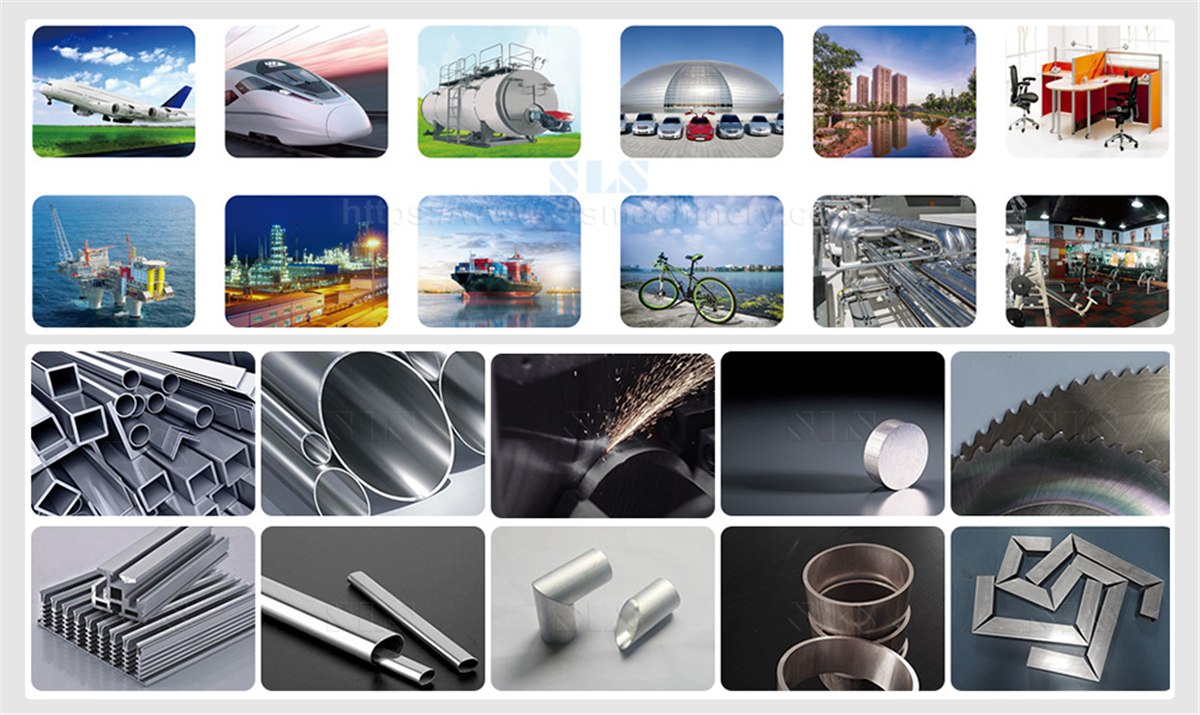

Main Application

Packaging & Shipping

Contact Us

SLS’s Efficiency Precision CNC Automatic Pipe Cutting And Chamfering Machine | The Complete Production Line Of Tube Cut Off Solutions

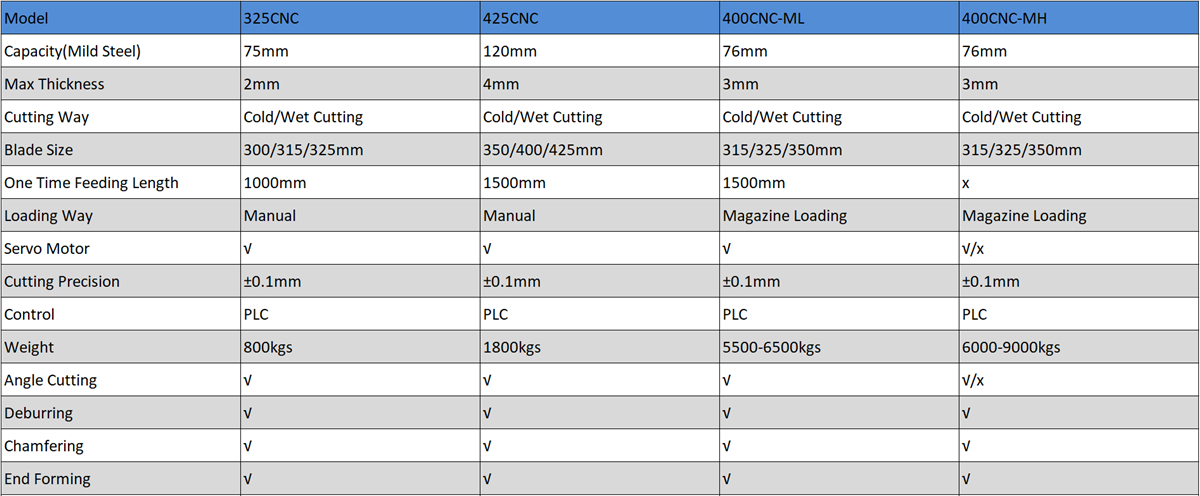

Main Technical Parameters Sheet

Brief Introduction on Precision CNC Automatic Pipe Cutting And Chamfering Machine

SLS’s Efficiency Precision CNC Automatic Pipe Cutting And Chamfering Machine | The Complete Production Line Of Tube Cut Off Solutions. Machine with Function of Pneumatic/Hydraulic Clamp, Servo Motor Feeding and Pneumatic/Hydraulic Cutting. Automatic Feeding Ensure High Cutting Accuracy and Increase Productivity. Good Mechanical System Ensures High Cutting Quality Without Burrs on Tube Internal and External. Water Cooling and Lubricate System Prolongs The Life of Machine and Saw Blade. Each Cold Saw Is Covered by One Year Parts Warranty Plus Lifetime Technical Support by SLS. We Keep Many Cold Saw Models In Stock for Quick Shipments.

Our Precision CNC Pipe Cutting And Chamfering Machine Is A Complete Automated Production Line Designed To Revolutionize The Pipe Cutting Process With Greater Accuracy, Speed And Versatility. The CNC Pipe Cutting Machine Can Not Only Achieve Efficient Cutting Of Pipes Made Of Various Metal Materials, But Can Also Customize Various Auxiliary Functions, Such As Pipe Chamfering And End Forming. (Expansion, Shrinkage, Sealing, Taper, Bending, Etc.) CNC Pipe Cutting Machines Are Widely Used In Various Industries Including Manufacturing, Construction, Automotive, Aerospace And Many Industries That Require Precise Pipe Cutting And Are Considered A Key Component Of Production And Assembly.

Features on Precision CNC Automatic Pipe Cutting And Chamfering Machine

● Adjustable Cutting Length Which Can Be Set on Touch Screen.

● Interactive PLC and Touch Screen Controlling Offers Easy Access to Auto And Manual Operating Modes.

● Automatic Servo Motor Feeding, Automatic Hydraulic Clamping and Automatic Hydraulic Cutting.

● Rigid Cast Iron Saw Bases and Electro-Welded Steel Frames Maintain Accuracy and Minimize Vibrations, Even At Full Capacity.

● Material of Tube Cutting Machine is Available:Steel&Stainless Steel.

● Cutting Shape Available: Round,Square,Rectangle and Other Profiles.

● Available for Several Pieces Cutting Together for Small Pipe Size.

● Clamping, Saw Blade Advancing and Backward, Clamp Releasing Are All Hydraulic Driven.

● 2 Sides and 2 Way Clamping System: High Precision Cutting, Reduce Vibration and Soundless While Cutting.

● Full Gear Machine Head Guarantee The Rigid And Stable Cutting Working Specially for Thick Tube Cutting.

● Good Cutting Quality for Tube Internal and External without Burs.

● Small Noisy

● Water Cooling and Lubricate System Prolongs The Life of Machine and Saw Blade.

● Good Mechanical Parts Ensure Machine Runs In High Stability.

● Optional:Feeding Rack for Cutting Pieces

● Optional:Customized Clamp Tool

● Optional: Angle Cutting

● Optional: Connect with Chamfering Machine

● Optional: Connect with Pipe Forming Machine

● Optional: Connect with Deburring Machine

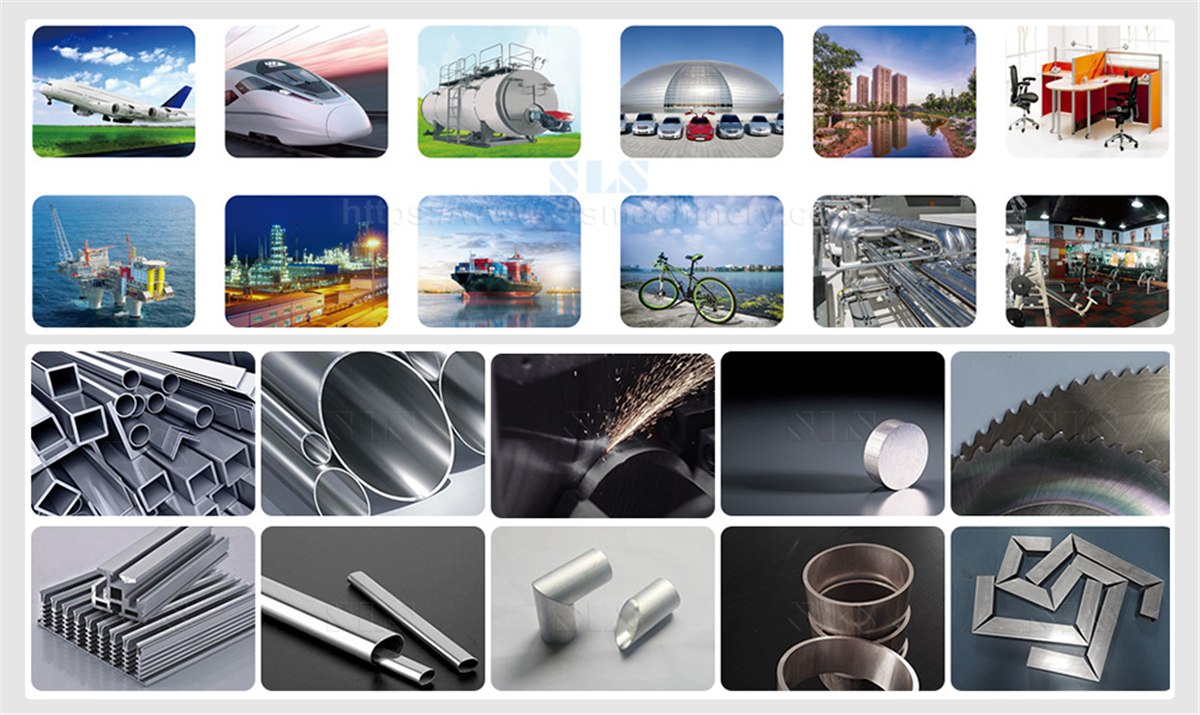

Main Application

Packaging & Shipping

Contact Us