+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

SLS-SB Series 76CNC Automatic Pipe Bending Machine Is Equipped with The Latest Electric Drive and Hydraulic Drive Technology. This Type of Automatic Tube Bending Machine Is Suitable for Thin-Walled or Thick-Walled Tubes and Special-Shaped Tubes. (Common Types of Tube Bending: Round, Oval, Square, Rectangular and Other Special Shapes.) 3D Multi-Dimensional Automatic Pipe Bending: High-Efficiency and High-Precision Tube Bending Technology, Which Can Meet the Needs of Tube Bending of Various Sizes...

_________________________________________________________________________

Model: 76CNC

Specification: 76mm(3")x3.5mm

Drive Mode: All Electric ( Servo motor drived )

Suit Bending: High precision -3D Bending (Multi Layers/Radius)

Business Type: Professoinal Manufacturer

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 45 Days Dated From Deposit Received

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

TEconomical Automatic Pipe Bending Machine | CNC Tube Bender - 76 Modle 5 Axis 3 Layer Dies with Push Bend

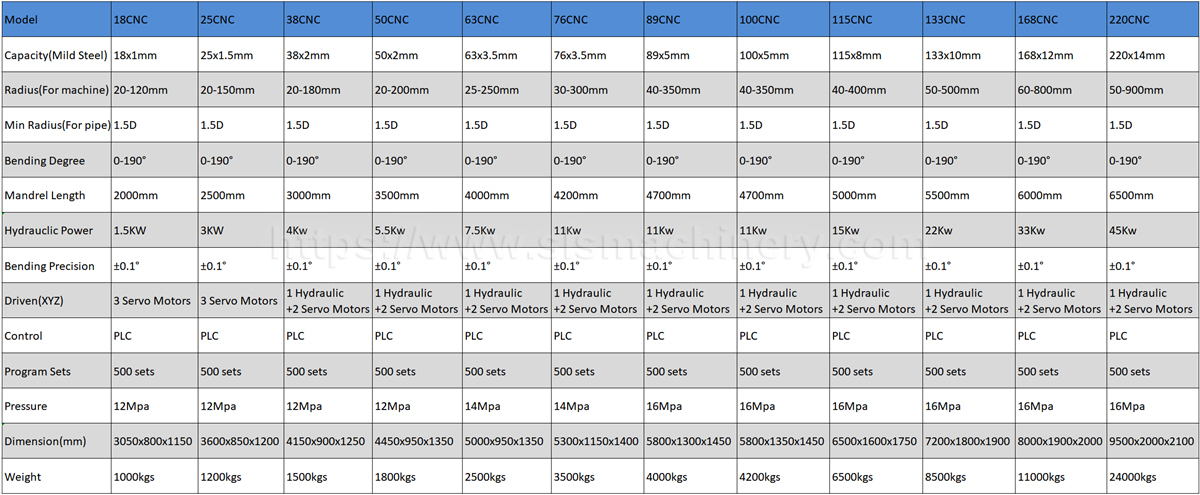

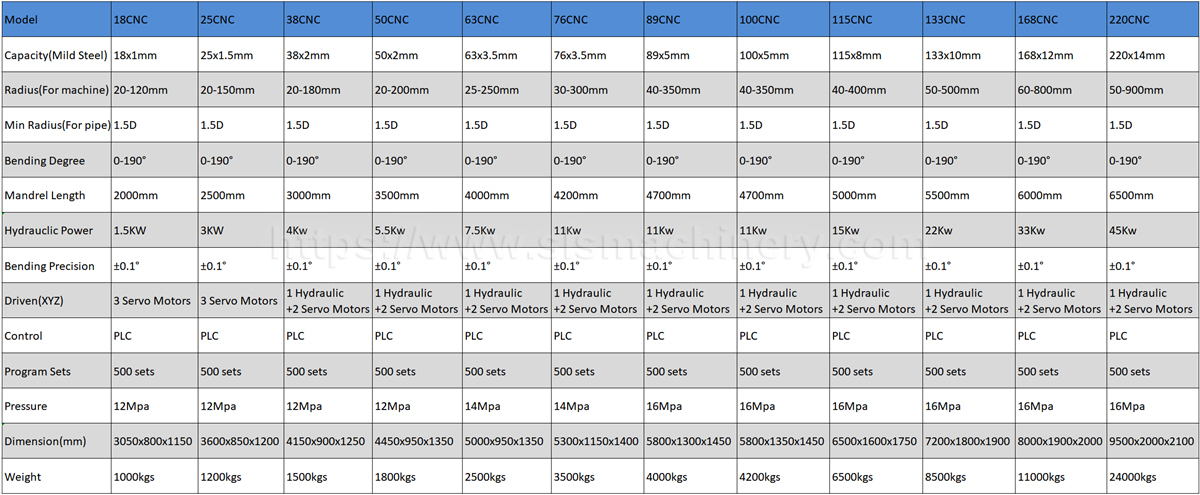

Main Technical Parameters Sheet

Brief Introduction on Automatic Pipe Bending Machine | CNC Tube Bender

SLS - Economical Automatic Pipe Bending Machine | CNC Tube Bender - 76 Modle 5 Axis 3 Layer Dies with Push Bend, It Equipped with PLC Which Manage Bending (Y), Feeding (X), Rotation (Z), Move Up and Down(A) & Move Left and Right(B) In a Complete Automatic Cycle.

5A:

Bending (Y-Axis): Controlled by Servomotor.

Feeding (X-Axis): Controlled by Servomotor.

Rotating (Z-Axis): Controlled by Servomotor.

Move Up and Down(A): Controlled by Servomotor.

Move Left and Right(B): Controlled by Servomotor.

3SV:

Three-Layer Mold + Auxiliary Push Bending To Meet The Requirements Of Higher Precision And More Complex Bending.

SLS Machinery Can Providing A One-Stop Fully Automatic Tube Bending Solution Means More Choices in Functions and Configurations. For Example: Multi-Layer Bending Dies with Automatic Die Change, Which Allow Various Radii and The Most Complex Tube Geometries to Be Achieved. Equipped With Push Bending, Even the Most Complex Bends Can Be Achieved with Extreme Precision.

SLS Machinery's Tube Bending Machines Are Designed to Provide Customers Around the World with The Highest Quality and Reliability, Providing You with The Most Economical Tube Bending Equipment That Meets the Most Demanding Requirements.

Features on Automatic Pipe Bending Machine | CNC Tube Bender

● Interactive PLC Touch Screen Offers Easy Access to Auto And Manual Operating Modes.

● Standard Clockwise Bending Direction.

● System Diagnostics and Multiple Language Capability.

● With Independent Programmable Speeds on Y, B(By Electrical Adjust) and C Axis(By Oil Flow Adjust).

● Maximum 500 Sets of Program Storage,Maximum 32 Bends for Each Program.

● Obtain Quality Repeatable Bends In Steel, Stainless, Aluminum, Titanium and Brass.

● Bending Axis-Driven by Cylinder,Feeding Axis-Driven by Servo Motor,Rotating Axis-Driven by Servo Motor.

● With Air Cooling System or Water Cooling System.

● One Set of Tooling for Draw Bending.

● Electric: As Required (3 Phase 220V or 380V or 415V...).

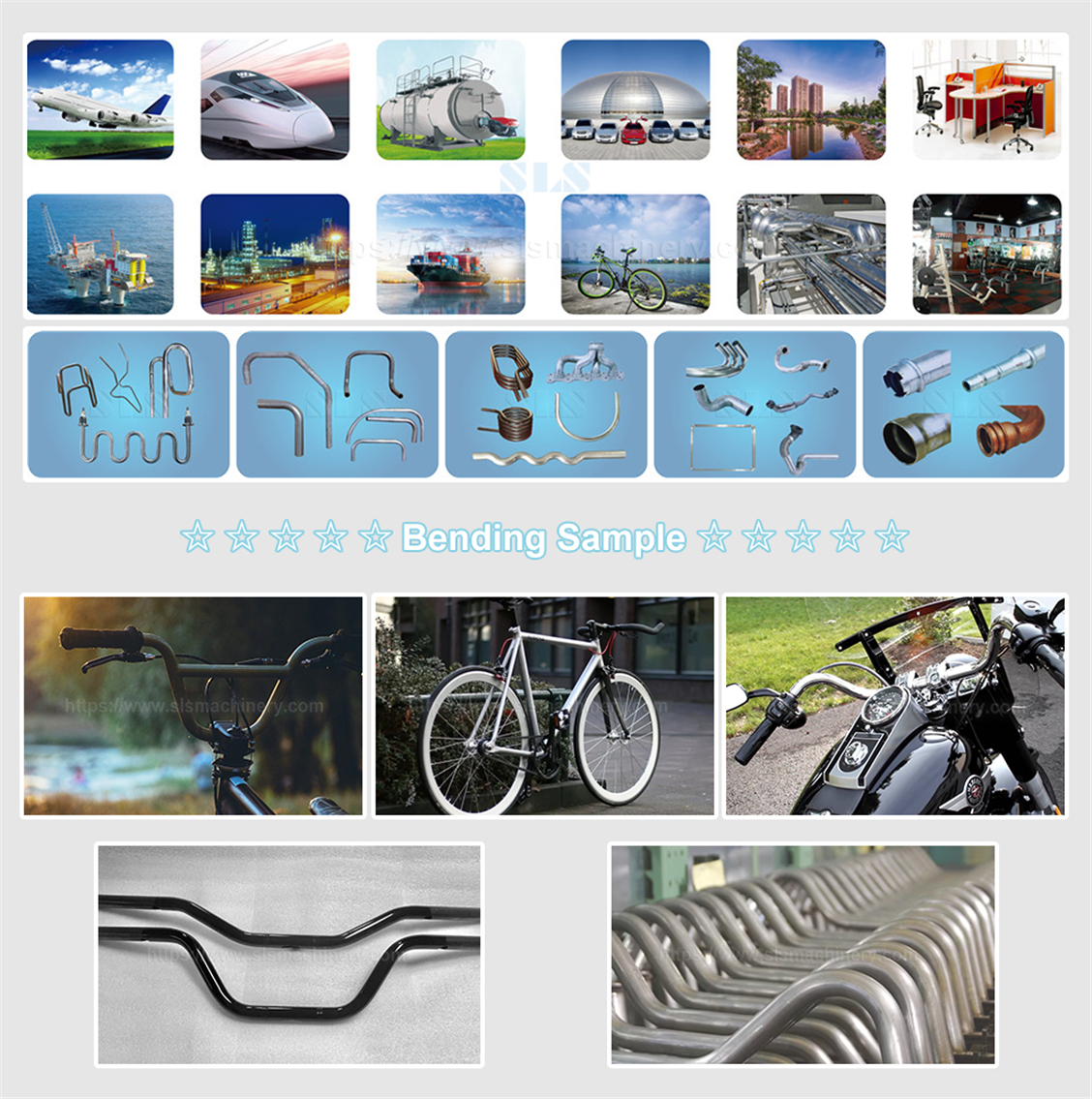

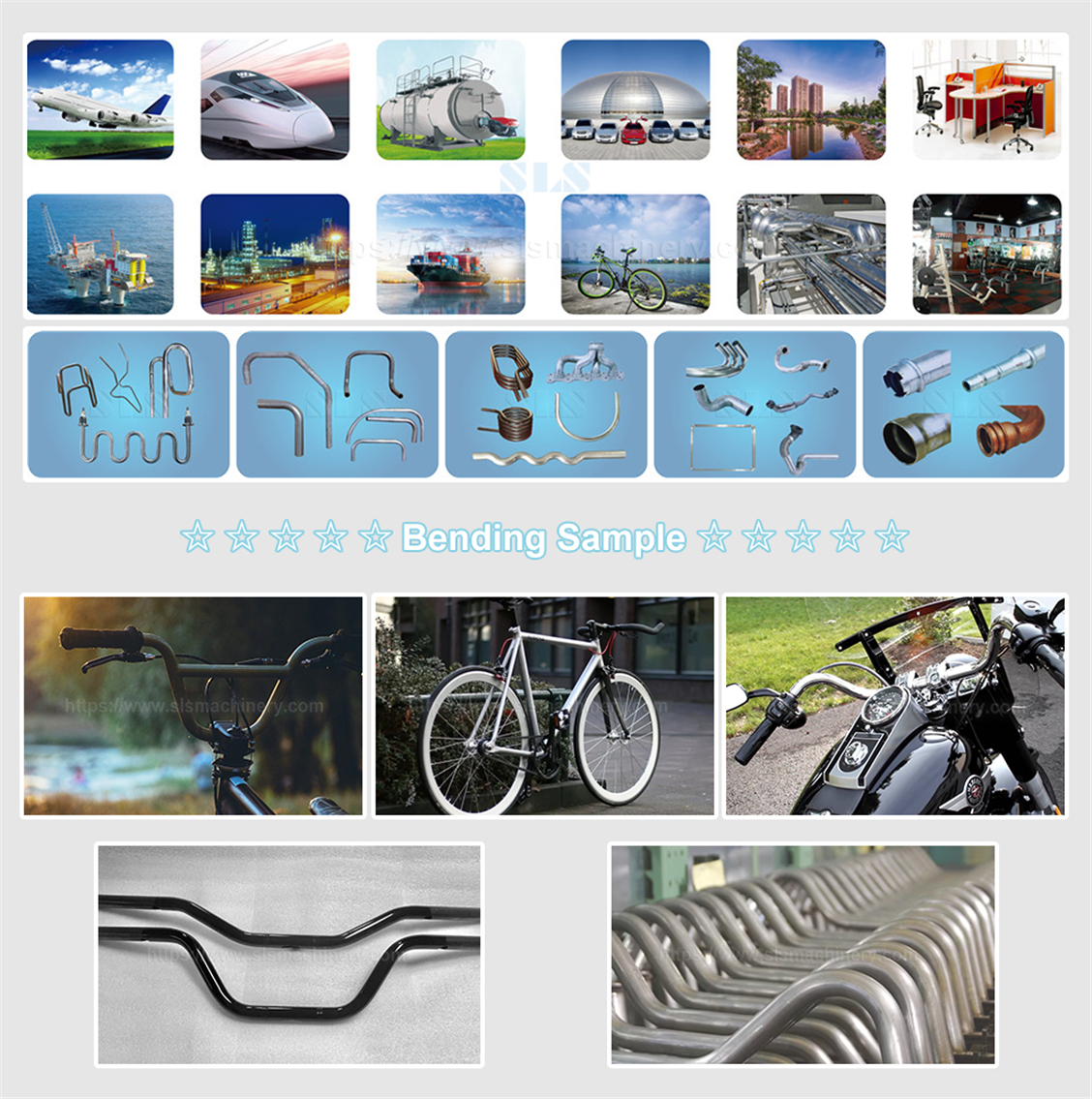

Main Application

Packaging & Shipping

Contact Us

TEconomical Automatic Pipe Bending Machine | CNC Tube Bender - 76 Modle 5 Axis 3 Layer Dies with Push Bend

Main Technical Parameters Sheet

Brief Introduction on Automatic Pipe Bending Machine | CNC Tube Bender

SLS - Economical Automatic Pipe Bending Machine | CNC Tube Bender - 76 Modle 5 Axis 3 Layer Dies with Push Bend, It Equipped with PLC Which Manage Bending (Y), Feeding (X), Rotation (Z), Move Up and Down(A) & Move Left and Right(B) In a Complete Automatic Cycle.

5A:

Bending (Y-Axis): Controlled by Servomotor.

Feeding (X-Axis): Controlled by Servomotor.

Rotating (Z-Axis): Controlled by Servomotor.

Move Up and Down(A): Controlled by Servomotor.

Move Left and Right(B): Controlled by Servomotor.

3SV:

Three-Layer Mold + Auxiliary Push Bending To Meet The Requirements Of Higher Precision And More Complex Bending.

SLS Machinery Can Providing A One-Stop Fully Automatic Tube Bending Solution Means More Choices in Functions and Configurations. For Example: Multi-Layer Bending Dies with Automatic Die Change, Which Allow Various Radii and The Most Complex Tube Geometries to Be Achieved. Equipped With Push Bending, Even the Most Complex Bends Can Be Achieved with Extreme Precision.

SLS Machinery's Tube Bending Machines Are Designed to Provide Customers Around the World with The Highest Quality and Reliability, Providing You with The Most Economical Tube Bending Equipment That Meets the Most Demanding Requirements.

Features on Automatic Pipe Bending Machine | CNC Tube Bender

● Interactive PLC Touch Screen Offers Easy Access to Auto And Manual Operating Modes.

● Standard Clockwise Bending Direction.

● System Diagnostics and Multiple Language Capability.

● With Independent Programmable Speeds on Y, B(By Electrical Adjust) and C Axis(By Oil Flow Adjust).

● Maximum 500 Sets of Program Storage,Maximum 32 Bends for Each Program.

● Obtain Quality Repeatable Bends In Steel, Stainless, Aluminum, Titanium and Brass.

● Bending Axis-Driven by Cylinder,Feeding Axis-Driven by Servo Motor,Rotating Axis-Driven by Servo Motor.

● With Air Cooling System or Water Cooling System.

● One Set of Tooling for Draw Bending.

● Electric: As Required (3 Phase 220V or 380V or 415V...).

Main Application

Packaging & Shipping

Contact Us