+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Our TM-100NC Type Double Head Tube End Expanding Machine | SLS Hydraulic Pipe Expander Forming Solutions, Machine Is Used To Enlarge The Opening Part Of The Pipe. It Is A Double-Head Pipe End Forming Machine With Extremely High Rigidity Structure, Specially Designed For End Forming Of Large Diameter Pipes.Provide Diversified Function Customization - Single-Station Or Multi-Station Molding Processing Operations Can Be Customized According To Customer Drawings Or Sample Workpiece Designs.The End Expansion Expansion Forming Machine Is Ideal For End Expansion, Crimping And Flaring Of Copper, Aluminum And Stainless Steel Pipe Fittings In Automobile Exhaust, Furniture, Air Conditioning, Refrigeration And Other Industries.Convenient Operation, High Precision And High Quality Are What We Pursue. We Are Professional Manufacturers Who Can Provide You With Complete Solutions.

_________________________________________________________________________

Model: TM-100NC/CNC

Specification: 100mm(4")x3.5mm

Drive Mode: Electric + Hydraulic

Technical: Tube Expanding ( End Forming )

Business Type: Professoinal Manufacturer

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 35 Days Dated From Deposit Received

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

TM-100NC Type Double Head Tube End Expanding Machine | SLS Hydraulic Pipe Expander Forming Solutions

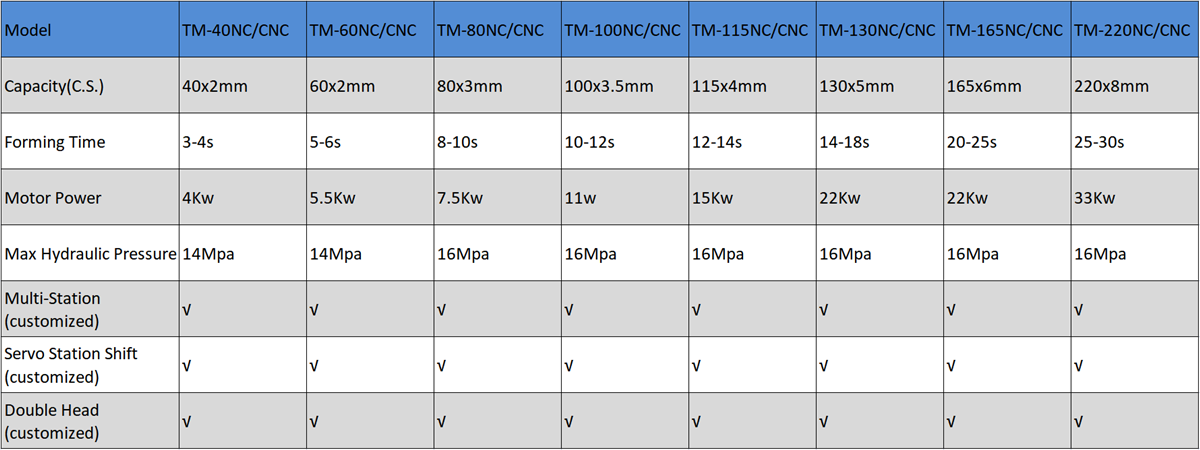

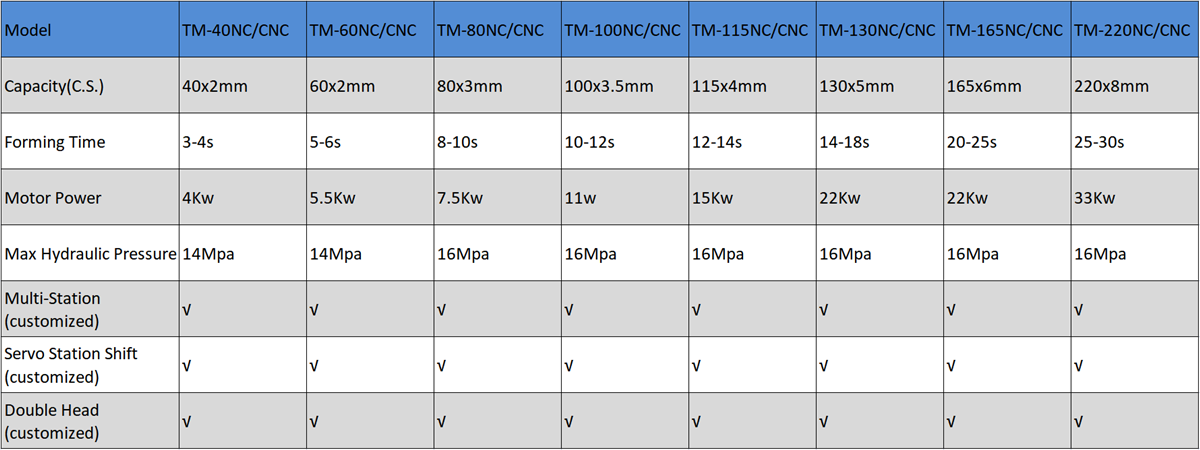

Main Technical Parameters Sheet

Brief Introduction on Double Head Tube End Expanding Machine

SLS TM-100NC Type Double Head Tube End Expanding Machine | SLS Hydraulic Pipe Expander Forming Solutions, Machine Is Used To Enlarge The Opening Part Of The Pipe. It Is A Double-Head Pipe End Forming Machine With Extremely High Rigidity Structure, Specially Designed For End Forming Of Large Diameter Pipes.Provide Diversified Function Customization - Single-Station Or Multi-Station Molding Processing Operations Can Be Customized According To Customer Drawings Or Sample Workpiece Designs.The End Expansion Expansion Forming Machine Is Ideal For End Expansion, Crimping And Flaring Of Copper, Aluminum And Stainless Steel Pipe Fittings In Automobile Exhaust, Furniture, Air Conditioning, Refrigeration And Other Industries.Convenient Operation, High Precision And High Quality Are What We Pursue. We Are Professional Manufacturers Who Can Provide You With Complete Solutions.

Features on Double Head Tube End Expanding Machine

● Both Ends Can Be Formed At One Time, Saving More Time And Greatly Improving Production Efficiency.

● Processing Size, Outer Diameter: 10-120mm Pipe.

● Full Hydraulic, Plunger And Clamping Cylinder.

● Adopting NC Control System And Touch Screen, It Is Easy To Operate.

● Hydraulic Cylinders Are Used To Control The Movement Of The Mold (More Than Two Stations), Which Is Accurate And Stable.

● It Adopts High-Precision Linear Guide Rail To Push Forward Smoothly.

● The Mold Change Adopts High-Performance Imported Hydraulic Valve Core. Simple Tool Change And Setup.

● Equipped With A Hydraulic Cooling System To Ensure Long-Term Stable Operation Under High Temperatures.

● The Mobile Foot Switch Has Two Functions: Start And Emergency Stop.

Main Application

Packaging & Shipping

Contact Us

TM-100NC Type Double Head Tube End Expanding Machine | SLS Hydraulic Pipe Expander Forming Solutions

Main Technical Parameters Sheet

Brief Introduction on Double Head Tube End Expanding Machine

SLS TM-100NC Type Double Head Tube End Expanding Machine | SLS Hydraulic Pipe Expander Forming Solutions, Machine Is Used To Enlarge The Opening Part Of The Pipe. It Is A Double-Head Pipe End Forming Machine With Extremely High Rigidity Structure, Specially Designed For End Forming Of Large Diameter Pipes.Provide Diversified Function Customization - Single-Station Or Multi-Station Molding Processing Operations Can Be Customized According To Customer Drawings Or Sample Workpiece Designs.The End Expansion Expansion Forming Machine Is Ideal For End Expansion, Crimping And Flaring Of Copper, Aluminum And Stainless Steel Pipe Fittings In Automobile Exhaust, Furniture, Air Conditioning, Refrigeration And Other Industries.Convenient Operation, High Precision And High Quality Are What We Pursue. We Are Professional Manufacturers Who Can Provide You With Complete Solutions.

Features on Double Head Tube End Expanding Machine

● Both Ends Can Be Formed At One Time, Saving More Time And Greatly Improving Production Efficiency.

● Processing Size, Outer Diameter: 10-120mm Pipe.

● Full Hydraulic, Plunger And Clamping Cylinder.

● Adopting NC Control System And Touch Screen, It Is Easy To Operate.

● Hydraulic Cylinders Are Used To Control The Movement Of The Mold (More Than Two Stations), Which Is Accurate And Stable.

● It Adopts High-Precision Linear Guide Rail To Push Forward Smoothly.

● The Mold Change Adopts High-Performance Imported Hydraulic Valve Core. Simple Tool Change And Setup.

● Equipped With A Hydraulic Cooling System To Ensure Long-Term Stable Operation Under High Temperatures.

● The Mobile Foot Switch Has Two Functions: Start And Emergency Stop.

Main Application

Packaging & Shipping

Contact Us