+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Our MC-315AC Type Semi-auto Metal Tube Cold Cut Saw Pneumatic Pipe Profile Cutting Machine Series Is Designed for Low Volume to Medium Production Applications on a Daily Basis, for Low Carbon Steel, Non-Ferrous Materials and Stainless Steels Within The Stated Capacities. Machine Can Be Realized Angle Cutting Which Greatly Increase The Cutting Feasibility. Our Metalworking Cold Saws Are Built With Rugged Construction That's Designed Specifically to Reduce Chatter and Wear to Give You a Superior Cut On Many Types Of Metal. It Is Much Safer and More Economical Cutting Machine for Your Choosing To Successful Cutting Just About Anywhere.

_________________________________________________________________________

Model: MC-315AC

Specification: 85mm x 2.5mm

Drive Mode: Electric + Pneumatic

Technical: Cold Saw Cutting

Business Type: Professoinal Manufacture

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 25 Days Dated From Deposit Received

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

MC-315AC Type Semi-auto Metal Tube Cold Cut Saw Pneumatic Pipe Profile Cutting Machine

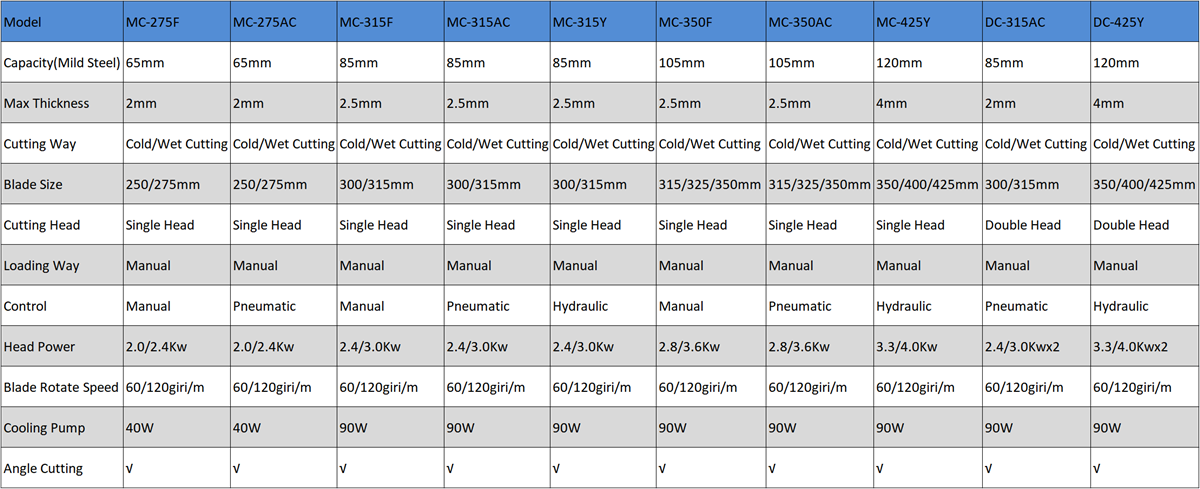

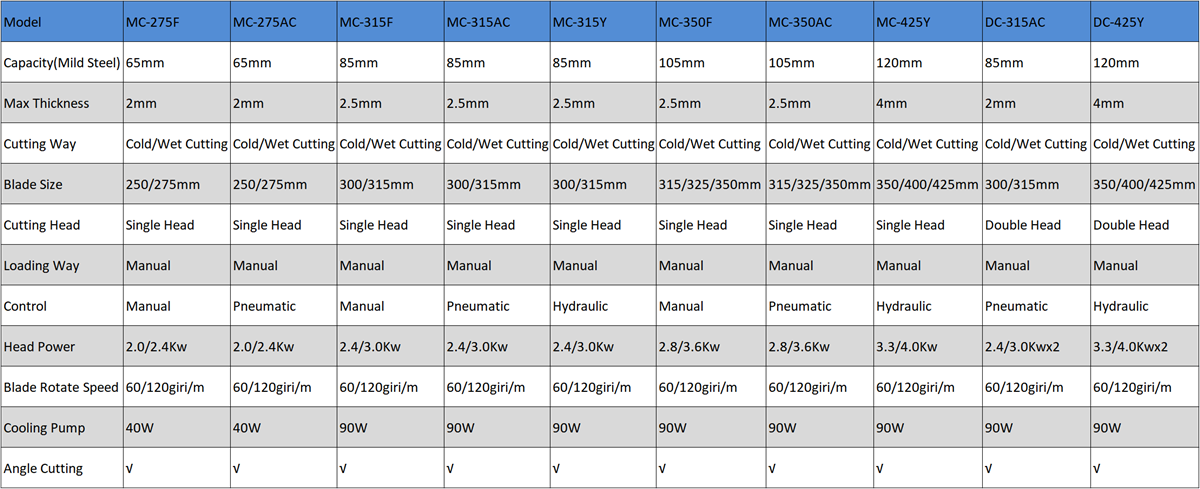

Main Technical Parameters Sheet

Brief Introduction on Cold Cut Saw Pneumatic Pipe Profile Cutting Machine

SLS MC-315AC Type Semi-auto Metal Tube Cold Cut Saw Pneumatic Pipe Profile Cutting Machine with Function of Pneumatic Clamp, Manual Feeding and Pneumatic Cutting. This Model Is Designed for Production Runs, Better Blade Life, Continuous Surface Finish, And to Eliminate Operator Fatigue. Saw Features Includes Semi-Auto Cycling, Which Requires The Operator to Just Push a Button or Foot Pedal While The Saw Does The Rest. Machine Can Be Realized Angle Cutting Which Greatly Increase The Cutting Feasibility. Good Mechanical System Ensures High Cutting Quality Without Burrs on Tube Internal and External. Water Cooling and Lubricate System Prolongs The Life of Machine and Saw Blade. We Keep Many Cold Saw Models In Stock for Quick Shipments.

Features on Cold Cut Saw Pneumatic Pipe Profile Cutting Machine

● Air Operating System:Manual Feeding, Air Clamping and Air Cutting.

● Strengthened and High Precision Flexible Cutting Head (2 Sides 45°): Able to Adjust Angle Freely, High Precision ofAngle, Easy and Quick Adjustment.

● 2 Sides and 2 Way Clamping System: High Precision Cutting, Reduce Vibration and Soundless While Cutting.

● High Perform of Worm Gear Set: High Perform Compare With Bend Saw Type or Others.

● For Any Level of Production, We Use Only High-Quality Components.

● Rigid Cast Iron Saw Bases and Electro-Welded Steel Frames Maintain Accuracy and Minimize Vibrations, Even At Full Capacity.

● Material Available: Steel&Stainless Steel

● Cutting Shape Available: Round, Square, Rectangle, Circular Saw Machine and Other Profiles...

● Available for Several Pieces Cutting Together for Small Pipe Size.

● Length Stopper Improve The Accuracy of Cutting Length.

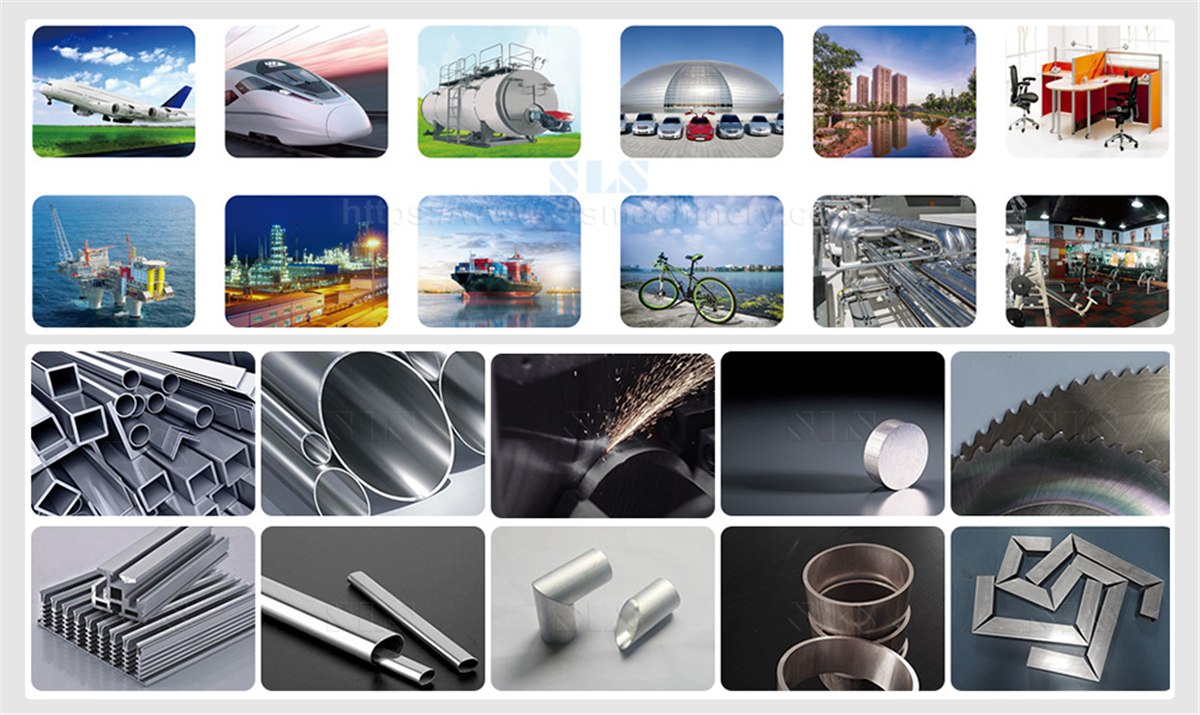

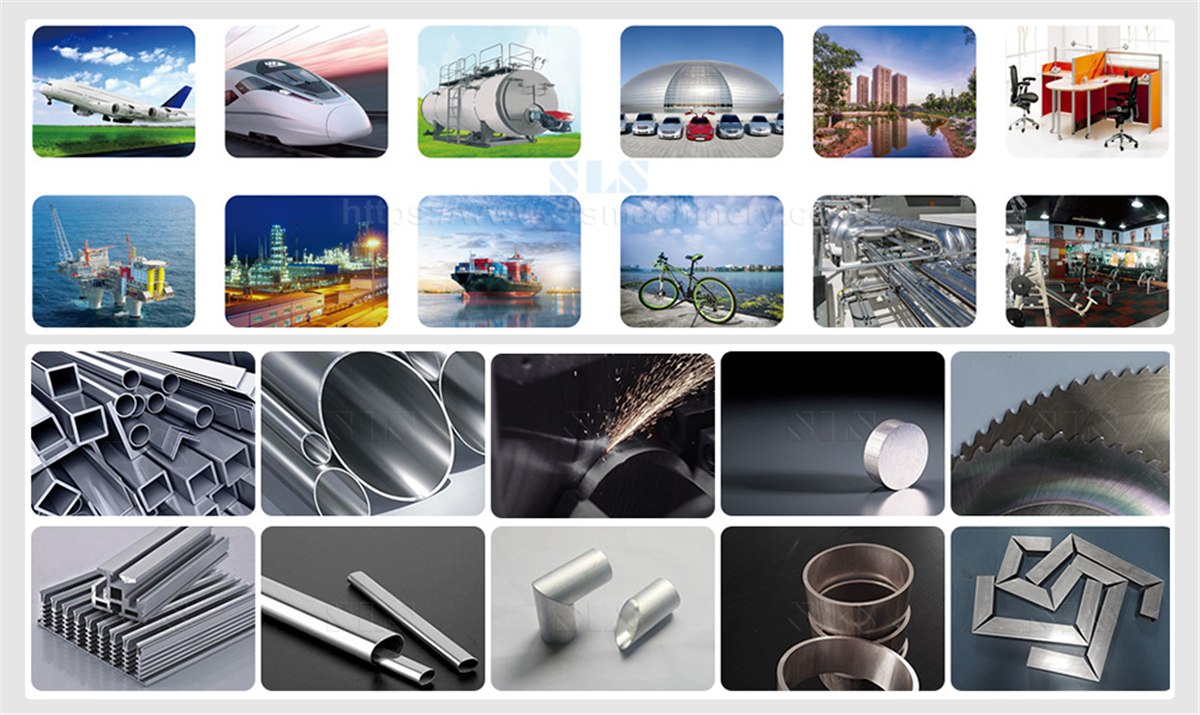

Main Application

Packaging & Shipping

Contact Us

MC-315AC Type Semi-auto Metal Tube Cold Cut Saw Pneumatic Pipe Profile Cutting Machine

Main Technical Parameters Sheet

Brief Introduction on Cold Cut Saw Pneumatic Pipe Profile Cutting Machine

SLS MC-315AC Type Semi-auto Metal Tube Cold Cut Saw Pneumatic Pipe Profile Cutting Machine with Function of Pneumatic Clamp, Manual Feeding and Pneumatic Cutting. This Model Is Designed for Production Runs, Better Blade Life, Continuous Surface Finish, And to Eliminate Operator Fatigue. Saw Features Includes Semi-Auto Cycling, Which Requires The Operator to Just Push a Button or Foot Pedal While The Saw Does The Rest. Machine Can Be Realized Angle Cutting Which Greatly Increase The Cutting Feasibility. Good Mechanical System Ensures High Cutting Quality Without Burrs on Tube Internal and External. Water Cooling and Lubricate System Prolongs The Life of Machine and Saw Blade. We Keep Many Cold Saw Models In Stock for Quick Shipments.

Features on Cold Cut Saw Pneumatic Pipe Profile Cutting Machine

● Air Operating System:Manual Feeding, Air Clamping and Air Cutting.

● Strengthened and High Precision Flexible Cutting Head (2 Sides 45°): Able to Adjust Angle Freely, High Precision ofAngle, Easy and Quick Adjustment.

● 2 Sides and 2 Way Clamping System: High Precision Cutting, Reduce Vibration and Soundless While Cutting.

● High Perform of Worm Gear Set: High Perform Compare With Bend Saw Type or Others.

● For Any Level of Production, We Use Only High-Quality Components.

● Rigid Cast Iron Saw Bases and Electro-Welded Steel Frames Maintain Accuracy and Minimize Vibrations, Even At Full Capacity.

● Material Available: Steel&Stainless Steel

● Cutting Shape Available: Round, Square, Rectangle, Circular Saw Machine and Other Profiles...

● Available for Several Pieces Cutting Together for Small Pipe Size.

● Length Stopper Improve The Accuracy of Cutting Length.

Main Application

Packaging & Shipping

Contact Us