+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

SLS's DEF-50Y Bar Chamfering Machine Is An Advanced Processing Equipment Designed For Precision Chamfering Of Metal Bars. This Machine Is Ideal For Achieving Smooth Deburring, Angled Edge Cuts On Bar Ends For Enhanced Safety And Aesthetics. It Is Equipped With A Powerful Motor And High-Quality Cutting Tools To Ensure Efficient And Accurate Chamfering Of A Variety Of Bar Sizes And Materials Including Steel, Iron, Copper, Aluminum And Other Metals. The Machine Features Adjustable Settings To Accommodate Different Chamfer Angles And Diameters Of Tubes And Rods, Providing Versatility For Different Applications. The Machine Has The Characteristics Of Safety And Durability, Low Maintenance Cost, Simple Operation And High Efficiency...

_________________________________________________________________________

Model: DEF-50Y

Specification: 50mm ( Pipe & Bar )

Drive Mode: Electric + Hydraulic

Technical: Debur Chamfering ( Double Heads )

Business Type: Professoinal Manufacturer

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 35 Days Dated From Deposit Received

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

SLS’s Double Heads Chamfering Machine | Automatic Solutions For Tube Debur Smoothing/Solid Rod Bars & Pipes End Facing

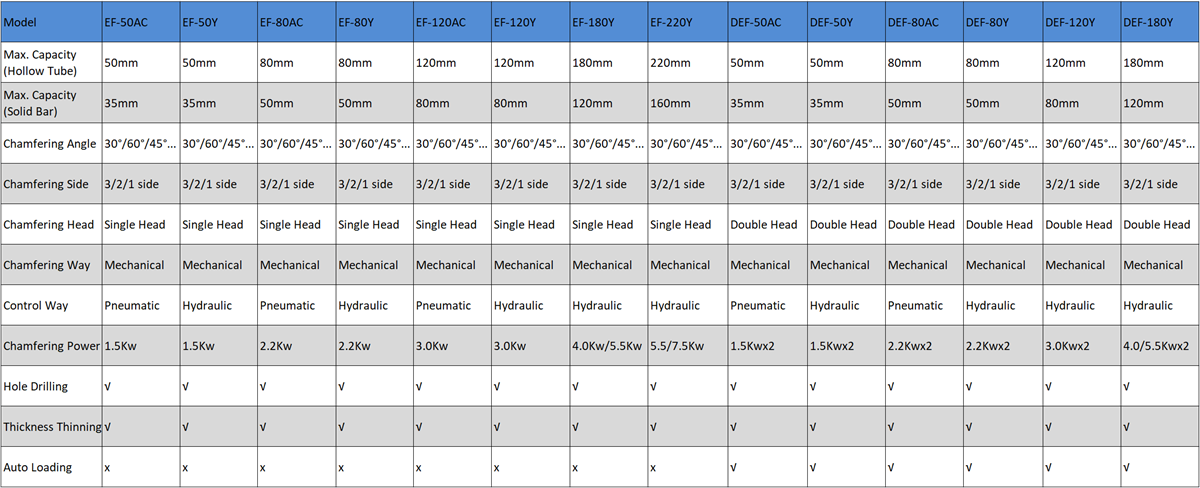

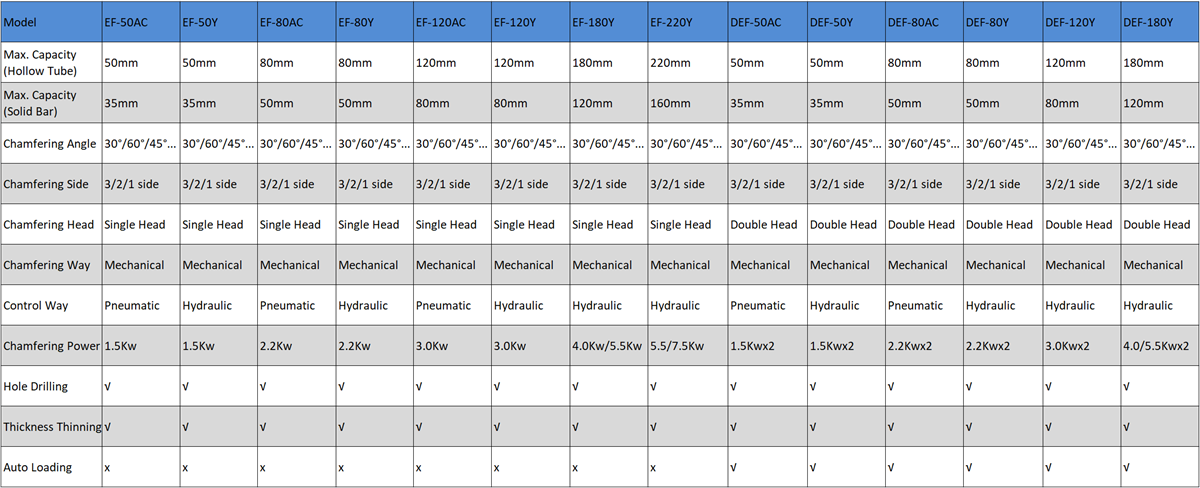

Main Technical Parameters Sheet

Brief Introduction on Solutions For Tube Debur Smoothing/ Bars & Pipes End Facing

SLS's DEF-50Y Bar Chamfering Machine Is An Advanced Processing Equipment Designed For Precision Chamfering Of Metal Bars. This Machine Is Ideal For Achieving Smooth Deburring, Angled Edge Cuts On Bar Ends For Enhanced Safety And Aesthetics. It Is Equipped With A Powerful Motor And High-Quality Cutting Tools To Ensure Efficient And Accurate Chamfering Of A Variety Of Bar Sizes And Materials Including Steel, Iron, Copper, Aluminum And Other Metals. The Machine Features Adjustable Settings To Accommodate Different Chamfer Angles And Diameters Of Tubes And Rods, Providing Versatility For Different Applications. The Machine Has The Characteristics Of Safety And Durability, Low Maintenance Cost, Simple Operation And High Efficiency. We Offer A Variety Of Options, Such As: Manual, Semi-Automatic And Fully-Automatic Bar Precision Chamfering (Chamfering, Taper) Machines, As Well As Special Tool Customization And Design To Meet Your Different Processing Needs. Commitment To Innovation And Quality Is Reflected In The Practical Performance Of Its Bar Chamfering Machines.

Features on Solutions For Tube Debur Smoothing/ Bars & Pipes End Facing

● Control Panel Offers Easy Access to Auto and Manual Operating Modes.

● All The Parts Are Made Under Very Strict Quality Control, So The Quality of Machine Is In High Level and The Specification Is Standardized.

● Equipped with Emergency Stop Device.

● A Circular Tube Modifies An Interior Angle, An External Angle and Flat Plane At One Time With Fastness and Precision.

● Automatic and Manual Working Mode Which Are Convenient for Adjusting The Machine, Mold and Chamfering Knife.

● Material Available: Carbon Steel, Stainless Steel, Copper, Aluminum...

● Chamfering Work Is Driven By Mechanical and Clamping Work Driven By Pneumatic.

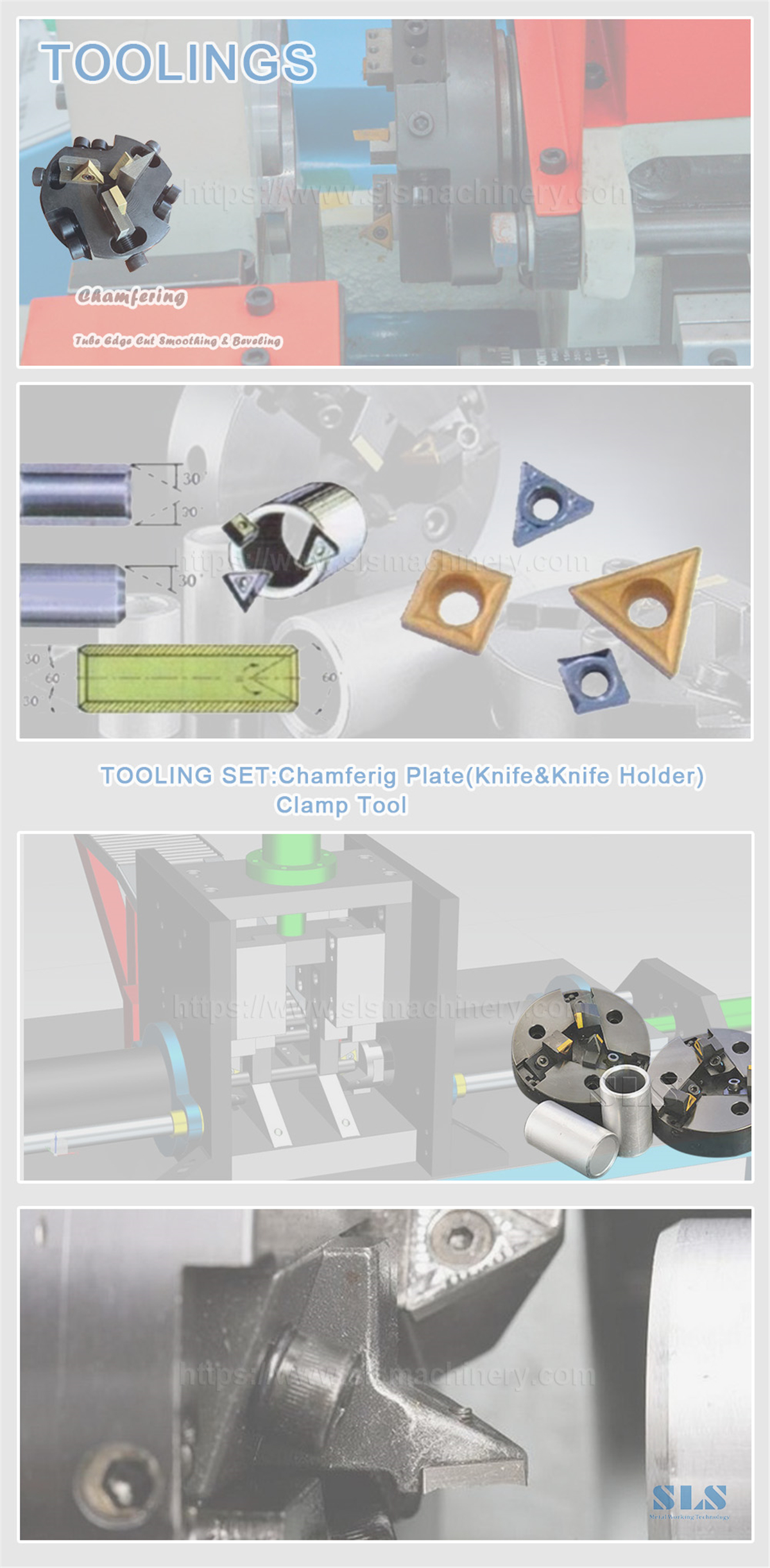

● Clamp Device and Knife Holder Are Precisely Designed for Ensure The Center Line Between Workpiece and Knife Holder At The Same Level.

● Dual Feed Chamfer System:

First Speed------Fast Forward Movement Nearly to Tube End to Save The Time.

Second Speed---Infinitely Variable Forward Adjustable Chamfering Speed to Get Smooth Finish.

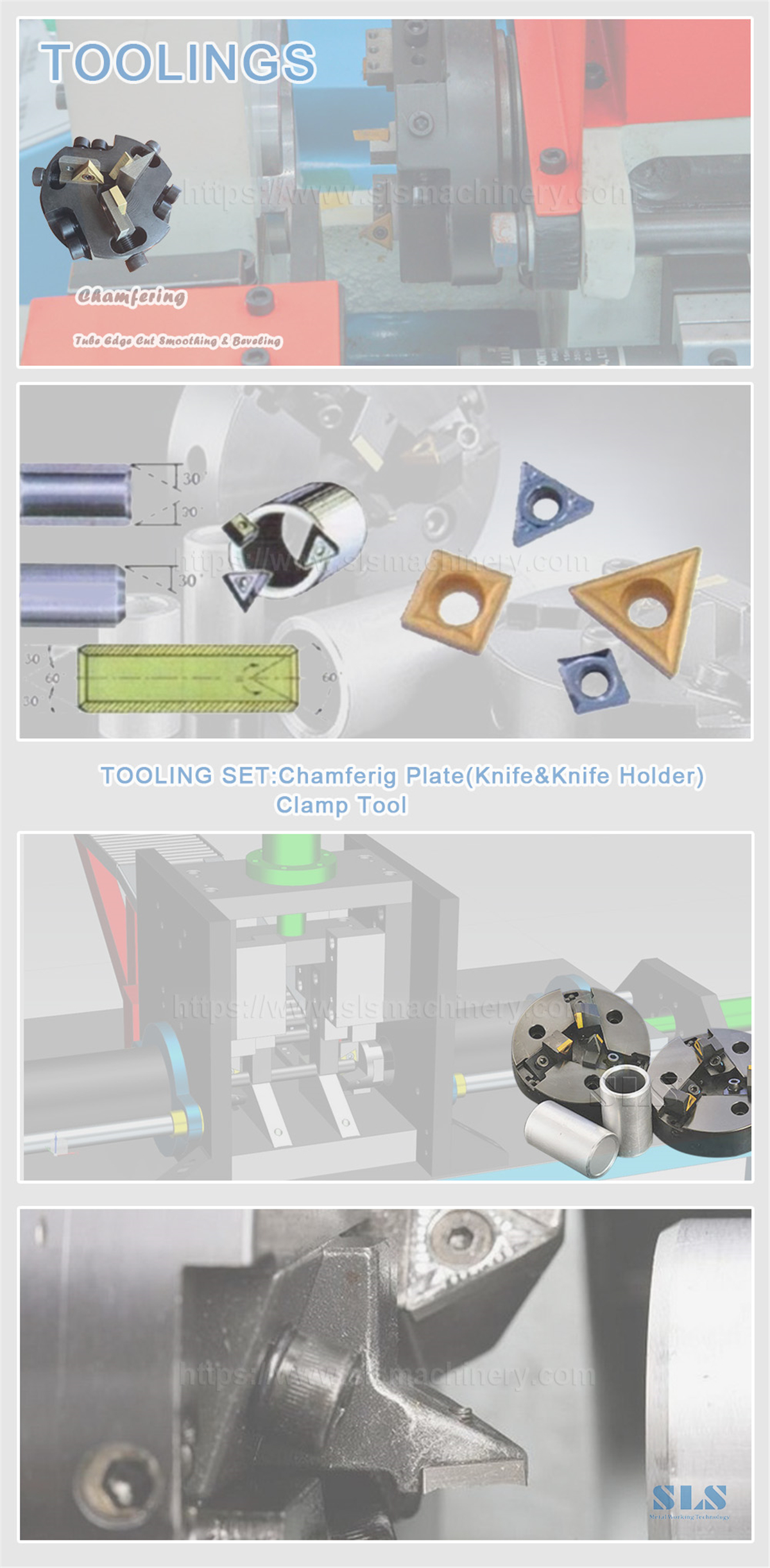

● The Design of The Tooling Help Customer Easy to Change.

● Foot Pedal Cycle Start.

● Optional: An Additional Feeding System Can Be Added to The Machine.

The Operating Security Is Greatly Increased Because The Operators Just Do The Unloading & Collecting Job of Finished Pipes.

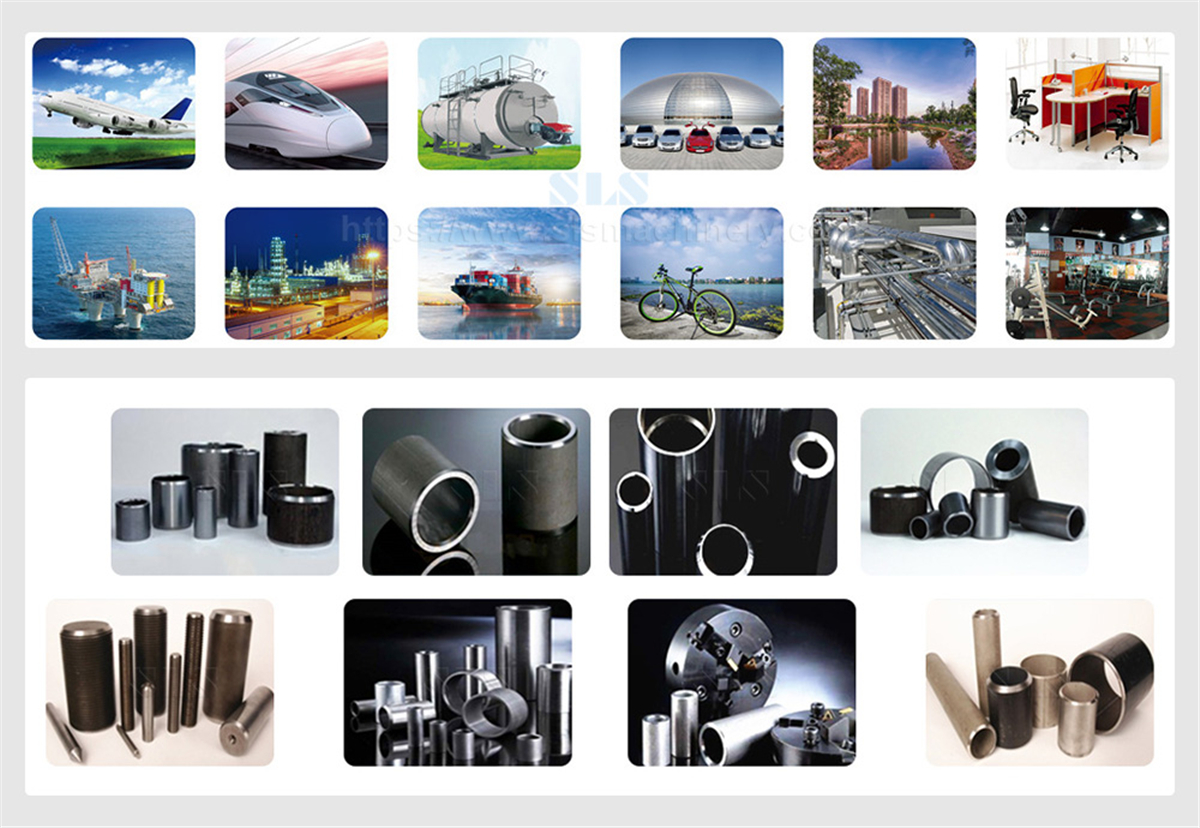

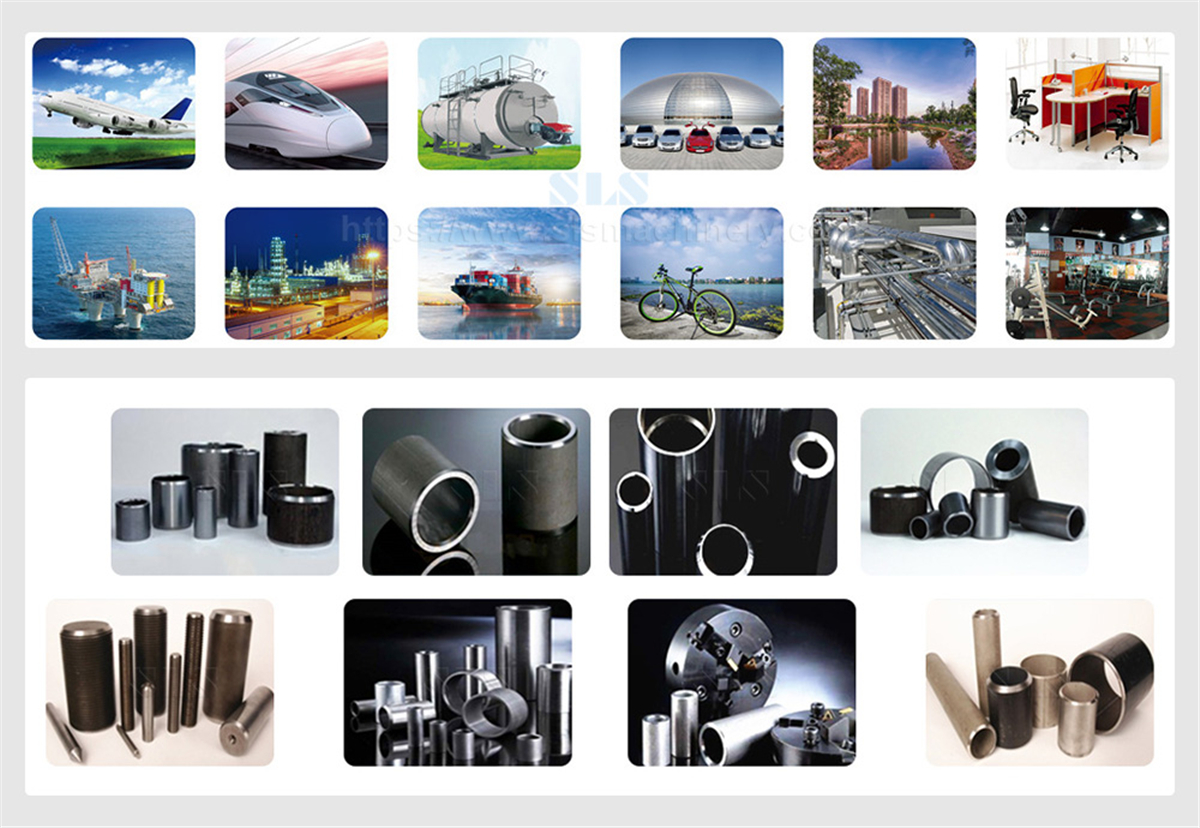

Main Application

Packaging & Shipping

Contact Us

SLS’s Double Heads Chamfering Machine | Automatic Solutions For Tube Debur Smoothing/Solid Rod Bars & Pipes End Facing

Main Technical Parameters Sheet

Brief Introduction on Solutions For Tube Debur Smoothing/ Bars & Pipes End Facing

SLS's DEF-50Y Bar Chamfering Machine Is An Advanced Processing Equipment Designed For Precision Chamfering Of Metal Bars. This Machine Is Ideal For Achieving Smooth Deburring, Angled Edge Cuts On Bar Ends For Enhanced Safety And Aesthetics. It Is Equipped With A Powerful Motor And High-Quality Cutting Tools To Ensure Efficient And Accurate Chamfering Of A Variety Of Bar Sizes And Materials Including Steel, Iron, Copper, Aluminum And Other Metals. The Machine Features Adjustable Settings To Accommodate Different Chamfer Angles And Diameters Of Tubes And Rods, Providing Versatility For Different Applications. The Machine Has The Characteristics Of Safety And Durability, Low Maintenance Cost, Simple Operation And High Efficiency. We Offer A Variety Of Options, Such As: Manual, Semi-Automatic And Fully-Automatic Bar Precision Chamfering (Chamfering, Taper) Machines, As Well As Special Tool Customization And Design To Meet Your Different Processing Needs. Commitment To Innovation And Quality Is Reflected In The Practical Performance Of Its Bar Chamfering Machines.

Features on Solutions For Tube Debur Smoothing/ Bars & Pipes End Facing

● Control Panel Offers Easy Access to Auto and Manual Operating Modes.

● All The Parts Are Made Under Very Strict Quality Control, So The Quality of Machine Is In High Level and The Specification Is Standardized.

● Equipped with Emergency Stop Device.

● A Circular Tube Modifies An Interior Angle, An External Angle and Flat Plane At One Time With Fastness and Precision.

● Automatic and Manual Working Mode Which Are Convenient for Adjusting The Machine, Mold and Chamfering Knife.

● Material Available: Carbon Steel, Stainless Steel, Copper, Aluminum...

● Chamfering Work Is Driven By Mechanical and Clamping Work Driven By Pneumatic.

● Clamp Device and Knife Holder Are Precisely Designed for Ensure The Center Line Between Workpiece and Knife Holder At The Same Level.

● Dual Feed Chamfer System:

First Speed------Fast Forward Movement Nearly to Tube End to Save The Time.

Second Speed---Infinitely Variable Forward Adjustable Chamfering Speed to Get Smooth Finish.

● The Design of The Tooling Help Customer Easy to Change.

● Foot Pedal Cycle Start.

● Optional: An Additional Feeding System Can Be Added to The Machine.

The Operating Security Is Greatly Increased Because The Operators Just Do The Unloading & Collecting Job of Finished Pipes.

Main Application

Packaging & Shipping

Contact Us