+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Our Boiler Pipe Serpentine Bending Machine | Two Heads - Left and Right Double Head CNC Tube Bender ( DH-76CNC-3A-2S-LR ) - DB booster is SLS’s answer to the specific needs of heat-exchanger, the boiler, waste burner and steam sectors - giving your business the boost it needs. The ideal solution for the efficient series production of tube serpentines, the CNC DB range of automatic booster bending machines is equipped with an intuitive CNC multi-axis control unit, an integrated tube positioning device and a smart booster with programmable boost factor. The CNC DB machines are particularly precise and primarily suitable for the mandrel-free bending of boiler tubes and tube serpentines. To control the booster effect on the bend, the user can dynamically manage its behaviour throughout the bending process - from 0° to 192° - using the machine software interface. Technical information: Ø38 x 4 @ CLR 32 (0.8 x OD) material: S275Users who require more process customisation options can choose to add a flip-over table, terminal end bender, ejector or tube magazine...

_________________________________________________________________________

Model: DH-76CNC-3A-32S-LR

Specification: Square, Rectangle, Profile, Circle, Round Tubes - Wall Thickness ≤6mm

Drive Mode: Electric + Hydraulic ( Auto Bending )

Suit Bending: 3D Bends ( Big Radius )

Business Type: Professoinal Manufacturer

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 45 Days Dated From Deposit Received

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

Boiler Pipe Serpentine Bending Machine | Two Heads - Left and Right Double Head CNC Tube Bender ( DH-76CNC-3A-2S-LR )

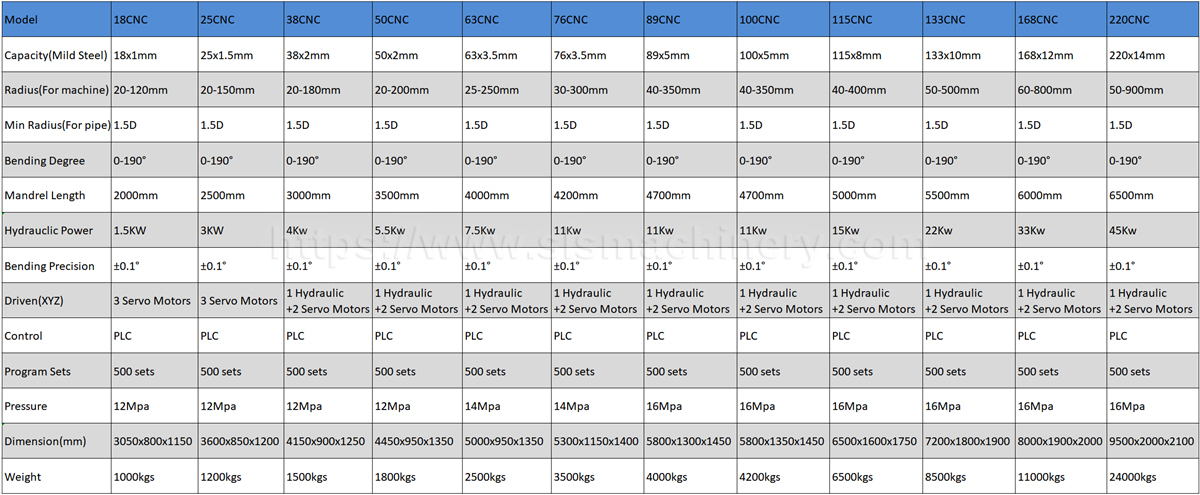

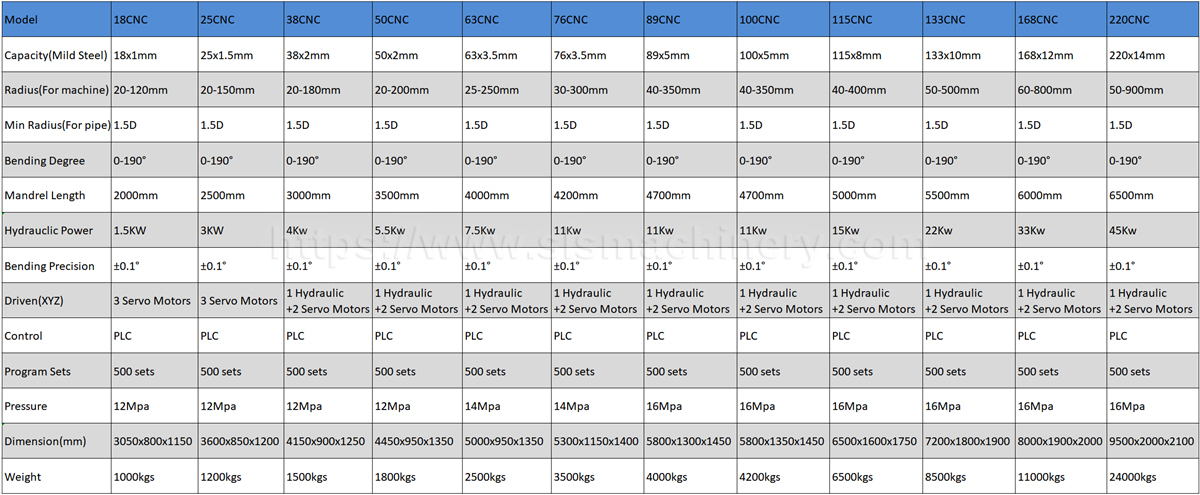

Main Technical Parameters Sheet

Brief Introduction on Two Heads - Left and Right Double Head CNC Tube Bender

Boiler Pipe Serpentine Bending Machine | Two Heads - Left and Right Double Head CNC Tube Bender ( DH-76CNC-3A-2S-LR ) Our DB booster is SLS’s answer to the specific needs of heat-exchanger, the boiler, waste burner and steam sectors - giving your business the boost it needs. The ideal solution for the efficient series production of tube serpentines, the CNC DB range of automatic booster bending machines is equipped with an intuitive CNC multi-axis control unit, an integrated tube positioning device and a smart booster with programmable boost factor. The CNC DB machines are particularly precise and primarily suitable for the mandrel-free bending of boiler tubes and tube serpentines. To control the booster effect on the bend, the user can dynamically manage its behaviour throughout the bending process - from 0° to 192° - using the machine software interface. Technical information: Ø38 x 4 @ CLR 32 (0.8 x OD) material: S275 Users who require more process customisation options can choose to add a flip-over table, terminal end bender, ejector or tube magazine.

The BOILER & POWER range of tube bending machines are designed specifically for continuous multi-shift operation in challenging conditions. Moreover, the cold bending process, which is gentle on the material, can also ensure that the microstructure of the high-strength and alternating-strength materials remains virtually unchanged.

The booster bending machines from our BOILER & POWER ranges outperform the tolerance specifications for wall thinning and ovality prescribed by all international standards including EN 12952 and ASME B31.1.

Thanks to our industry experience and technical expertise, we are able to offer you the right solution to ensure your lasting success.

Modern boiler and power plant construction requires high-performance machines capable of bending challenging materials to meet stringent specifications. For this reason, we developed a unique mandrel-free bending process that is benefiting many users worldwide. We can help you to continuously update your manufacturing process, at the same time making it more cost-effective. As well as automatic tube bending machines for boiler tubes and tube serpentines, the BOILER & POWER range also includes less expensive, semi-automatic variants, tube bending machines with two bending heads and membrane wall bending machines. Please feel free to contact us without obligation to discuss your individual requirements.

We are a world-leading company with decades of experience in developing and producing high-quality tube bending machines. From machines for custom manufacture and small batches and tube bending machines for large-scale production to special units for highly complex tube geometries – we have the right solution for every tube diameter, application and industry. Whether you are looking for a hydraulic, (part-)electric or hybrid drive, a smart EcoLine package or a combination with one of our modular equipment options, our portfolio includes the right solution for your specific needs.

See for yourself or contact us directly for an individual consultation.

DH-76CNC-3A-2S-LR:

Bending (Y-Axis): Controlled by Hydraulic Oil Pump Motor.

Feeding (X-Axis): Controlled by Servomotor.

Rotating (Z-Axis): Controlled by Servomotor.

Machine Head movement: Controlled by Servomotor.

2S-LR: 2-Layer bending, Left & Right Two Heads. - DIRECTIONAL BENDING

Features on Two Heads - Left and Right Double Head CNC Tube Bender

● Interactive PLC Touch Screen Offers Easy Access to Auto And Manual Operating Modes.

● Standard Clockwise Bending Direction.

● System Diagnostics and Multiple Language Capability.

● Obtain Quality Repeatable Bends In Metal Steel, Stainless, Aluminum, Copper, Alloy, Titanium and Brass.

● Maximum 600 Sets of Program Storage,Maximum 32 Bends for Each Program.

● With Independent Programmable Speeds on Y, B(By Electrical Adjust) and C Axis(By Oil Flow Adjust).

● Bending Axis-Driven by Cylinder,Feeding Axis-Driven by Servo Motor,Rotating Axis-Driven by Servo Motor.

● One Set of Tooling for Draw Bending.

● With Air Cooling System or Water Cooling System.

● Electric: As Required (3 Phase 220V or 380V or 415V...).

● CE & RD & OEM & ODM and More Support ...

Main Application

Packaging & Shipping

Contact Us

Boiler Pipe Serpentine Bending Machine | Two Heads - Left and Right Double Head CNC Tube Bender ( DH-76CNC-3A-2S-LR )

Main Technical Parameters Sheet

Brief Introduction on Two Heads - Left and Right Double Head CNC Tube Bender

Boiler Pipe Serpentine Bending Machine | Two Heads - Left and Right Double Head CNC Tube Bender ( DH-76CNC-3A-2S-LR ) Our DB booster is SLS’s answer to the specific needs of heat-exchanger, the boiler, waste burner and steam sectors - giving your business the boost it needs. The ideal solution for the efficient series production of tube serpentines, the CNC DB range of automatic booster bending machines is equipped with an intuitive CNC multi-axis control unit, an integrated tube positioning device and a smart booster with programmable boost factor. The CNC DB machines are particularly precise and primarily suitable for the mandrel-free bending of boiler tubes and tube serpentines. To control the booster effect on the bend, the user can dynamically manage its behaviour throughout the bending process - from 0° to 192° - using the machine software interface. Technical information: Ø38 x 4 @ CLR 32 (0.8 x OD) material: S275 Users who require more process customisation options can choose to add a flip-over table, terminal end bender, ejector or tube magazine.

The BOILER & POWER range of tube bending machines are designed specifically for continuous multi-shift operation in challenging conditions. Moreover, the cold bending process, which is gentle on the material, can also ensure that the microstructure of the high-strength and alternating-strength materials remains virtually unchanged.

The booster bending machines from our BOILER & POWER ranges outperform the tolerance specifications for wall thinning and ovality prescribed by all international standards including EN 12952 and ASME B31.1.

Thanks to our industry experience and technical expertise, we are able to offer you the right solution to ensure your lasting success.

Modern boiler and power plant construction requires high-performance machines capable of bending challenging materials to meet stringent specifications. For this reason, we developed a unique mandrel-free bending process that is benefiting many users worldwide. We can help you to continuously update your manufacturing process, at the same time making it more cost-effective. As well as automatic tube bending machines for boiler tubes and tube serpentines, the BOILER & POWER range also includes less expensive, semi-automatic variants, tube bending machines with two bending heads and membrane wall bending machines. Please feel free to contact us without obligation to discuss your individual requirements.

We are a world-leading company with decades of experience in developing and producing high-quality tube bending machines. From machines for custom manufacture and small batches and tube bending machines for large-scale production to special units for highly complex tube geometries – we have the right solution for every tube diameter, application and industry. Whether you are looking for a hydraulic, (part-)electric or hybrid drive, a smart EcoLine package or a combination with one of our modular equipment options, our portfolio includes the right solution for your specific needs.

See for yourself or contact us directly for an individual consultation.

DH-76CNC-3A-2S-LR:

Bending (Y-Axis): Controlled by Hydraulic Oil Pump Motor.

Feeding (X-Axis): Controlled by Servomotor.

Rotating (Z-Axis): Controlled by Servomotor.

Machine Head movement: Controlled by Servomotor.

2S-LR: 2-Layer bending, Left & Right Two Heads. - DIRECTIONAL BENDING

Features on Two Heads - Left and Right Double Head CNC Tube Bender

● Interactive PLC Touch Screen Offers Easy Access to Auto And Manual Operating Modes.

● Standard Clockwise Bending Direction.

● System Diagnostics and Multiple Language Capability.

● Obtain Quality Repeatable Bends In Metal Steel, Stainless, Aluminum, Copper, Alloy, Titanium and Brass.

● Maximum 600 Sets of Program Storage,Maximum 32 Bends for Each Program.

● With Independent Programmable Speeds on Y, B(By Electrical Adjust) and C Axis(By Oil Flow Adjust).

● Bending Axis-Driven by Cylinder,Feeding Axis-Driven by Servo Motor,Rotating Axis-Driven by Servo Motor.

● One Set of Tooling for Draw Bending.

● With Air Cooling System or Water Cooling System.

● Electric: As Required (3 Phase 220V or 380V or 415V...).

● CE & RD & OEM & ODM and More Support ...

Main Application

Packaging & Shipping

Contact Us