+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

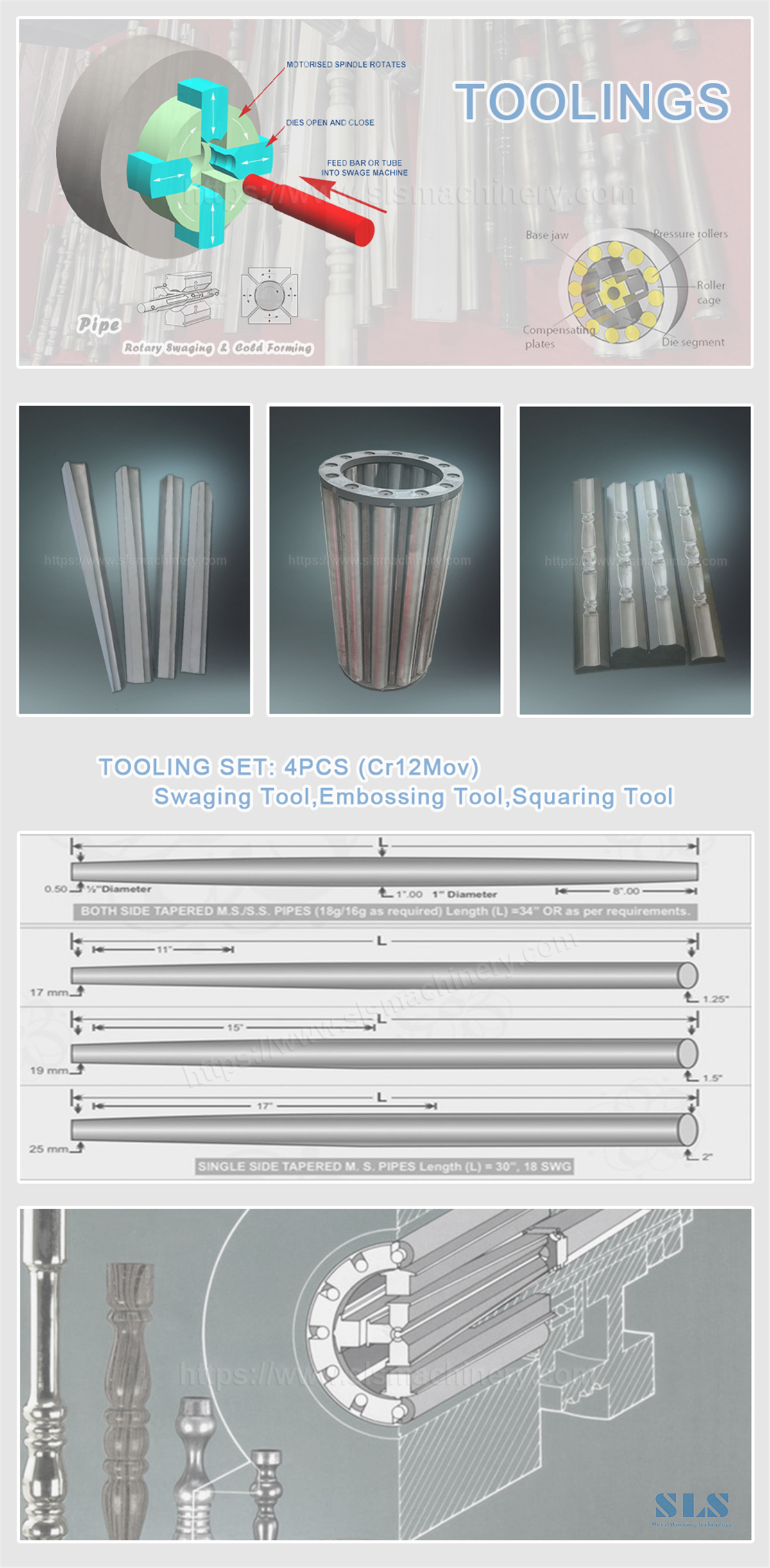

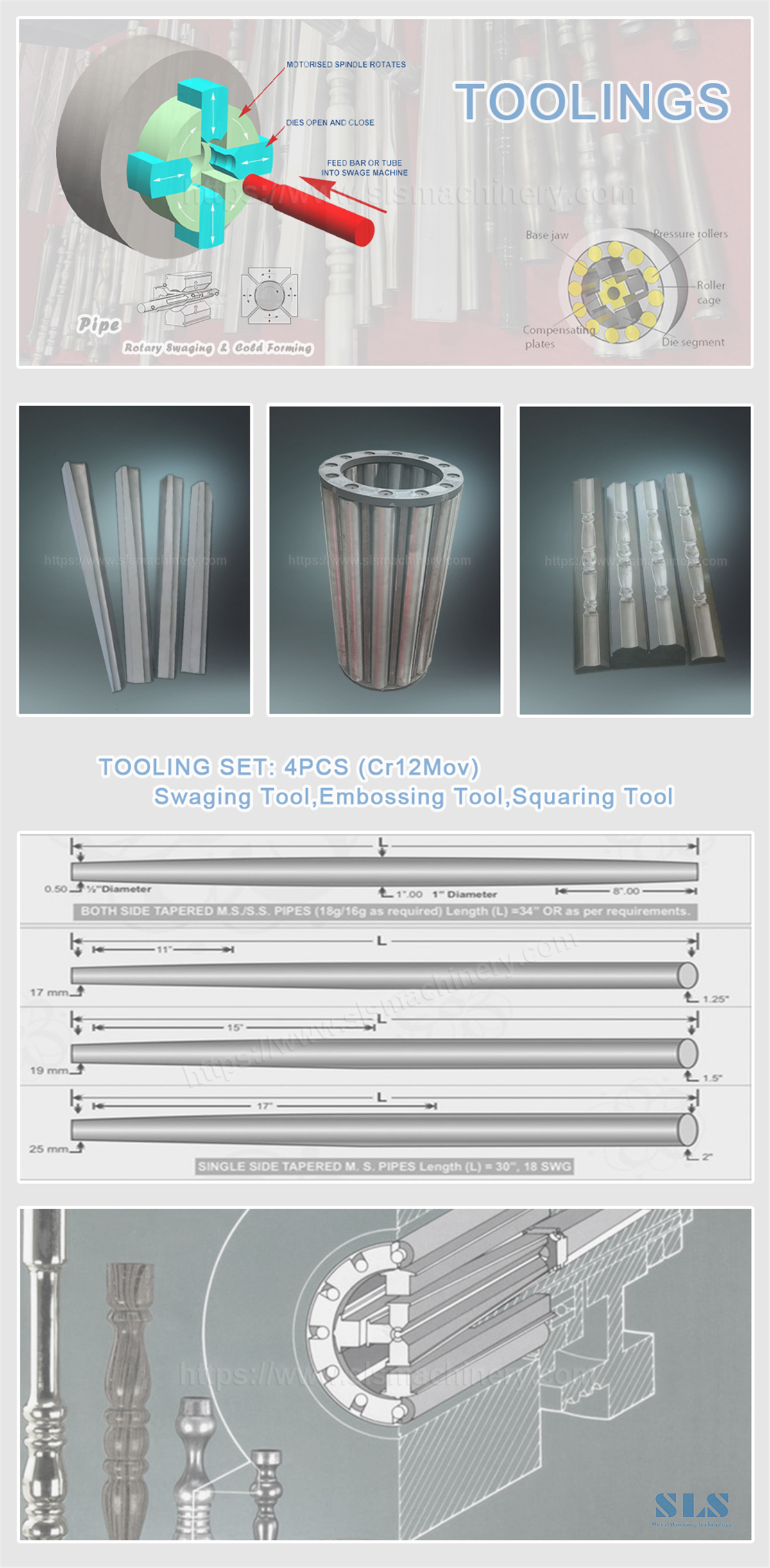

Our Pipe Rotary Swaging Machine Is A Pipe End Forming Machine. The Principle Is A Device Used To Reduce Or Form The End Of A Metal Pipe Or Solid Bar By Compressing It Through A Series Of Very Rapid Blows With A Die And A Rotary Hammer. That Is To Say, During The Rotary Forging Process, The Forming Die Driven By The Hammer Rotates Around The Workpiece. As The Spindle Rotates, Centrifugal Force Throws The Hammer And Die Outward Toward A Series Of Rollers Surrounding The Spindle. Each Time The Hammer Blocks Strike An Opposite Roll, They Are Driven Inward - Causing The Die Halves To Close And Compress The Metal Being Forged. Tube Swaging Forging Can Be Hot Forging Or Cold Forging, But Cold Forging Is More Popular Because It Can Not Only Harden Most Materials, But Also Improve The Grain Structure In The Process To Give Parts Greater Strength And An Unusually Fine Finish…

_________________________________________________________________________

Model: TF-76Y

Specification: 76mm(3")x2.5mm

Drive Mode: Mechanical & Hydraulic

Technical: Tube End Forming / Cold Forging ( 4 Rotary Hammers )

Business Type: Professoinal Manufacturer

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 35 Days Dated From Deposit Received

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

4 Rotary Hammers Pipe Swaging Machine | Tube End Forming Machine | Pipe Taper Reducing Swager

Main Technical Parameters Sheet

Brief Introduction on 4 Rotary Hammers Pipe Swaging Machine

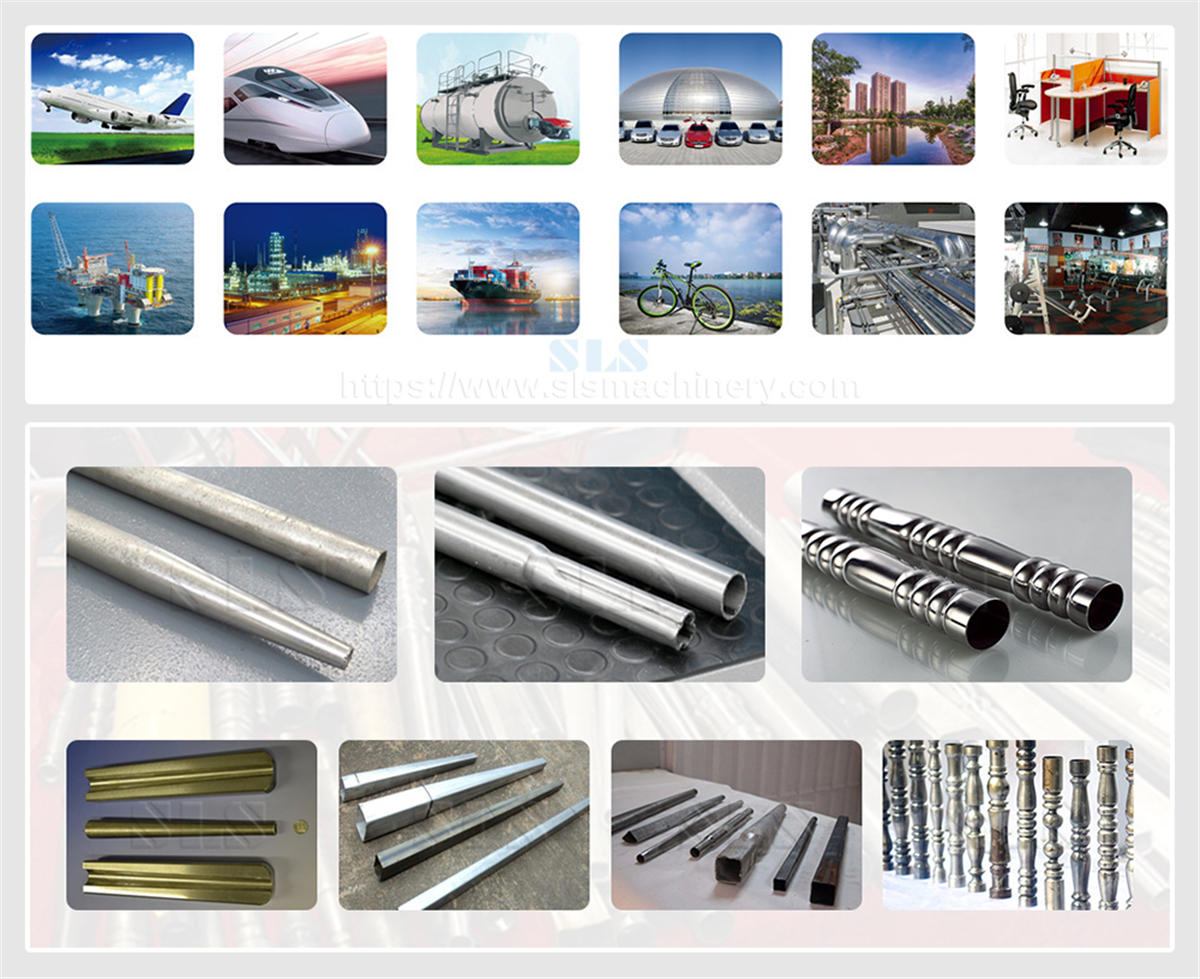

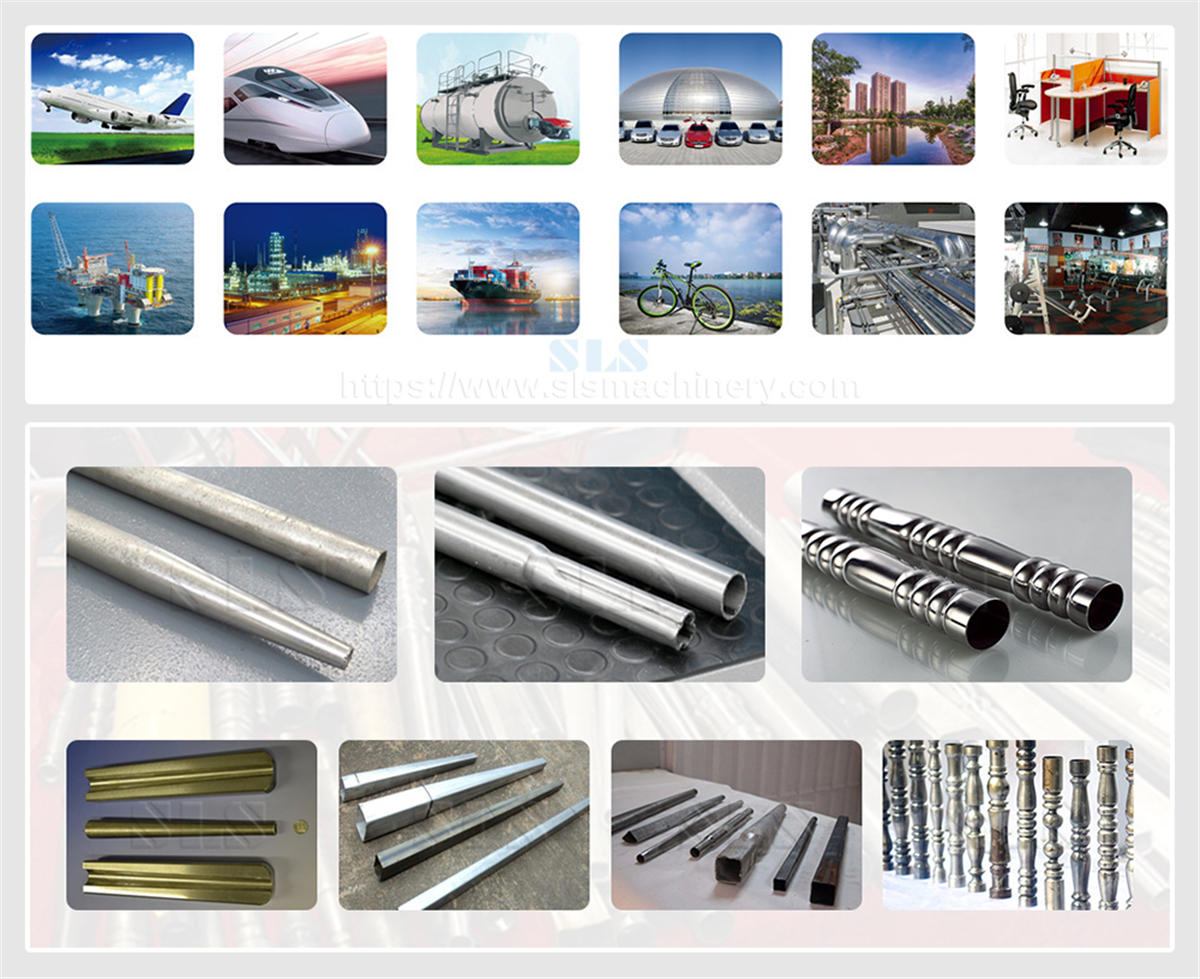

4 Rotary Hammers Pipe Swaging Machine | Tube End Forming Machine | Pipe Taper Reducing Swager, Our Machine Is The Best Choice For Designing And Processing Pipe Parts And Can Be Used For A Variety Of Non-Ferrous And Ferrous Materials. It Is Widely Used In Industries Such As Aerospace, Automotive, Medical, Military, Sporting Goods And Home Furnishing Industries To Produce Products. Swaging Is Essentially A Metal Forming Technology That Can Change The Size Of The End Of A Rod, Solid Bar, Or Pipe. Simply Put, Pipe Forging Is The Process Of Changing The Diameter (Taper) Of The Pipe End Through A Mold And A Rotating Hammer.

About Automation Solutions For Pipe Rotary Swaging Presses, SLS Designs And Fully Integrates Solutions To Maximize Efficiency And Reduce Press Operation Costs. SLS Is A Leader In The Metal Forming Industry, With Extensive Experience In Both Professionally Designing New Custom Systems And Retrofitting And Integrating New Systems Around Existing SLS Equipment. We Also Provide Replacement Parts, Tooling, Molds And Rebuild Services For Your Machine. Exceptional Customer Service, Repair/Rebuild Programs And Operator Training Put Our Machines In A Variety Of Applications Around The World. For Any Needs And Questions, Please Feel Free To Contact Us For Help.

Features on 4 Rotary Hammers Pipe Swaging Machine

● High Finish: Because The Finished Product Has A High Finish, Secondary Processing May Not Be Required, Saving Time And Money.

● Quick Assembly: The Taper Can Be Quickly Connected To Various Additional Components, Such As Industrial Pipelines, Auto Parts Axles, Metal Furniture Legs And Other Components.

● Uses Less Material: Material Moves Lengthwise When Hammered Instead Of Being Wastefully Chipped Away.

● Reduced Labor Costs: Easy To Operate And Does Not Require Highly Skilled Operators, Thus Reducing Labor Costs.

● Low Cost And Flexible Tooling: Rotary Press Tooling Is Incredibly Adaptable, And Die Changes Are Simple And Fast.

● Reduced Inventory Requirements: Since Swaging Can Be Done To The Required Size And Surface, There Are Fewer Existing Parts To Maintain.

● Using An Auxiliary Mandrel: The Wall Thickness Can Be Better Controlled During The Entire Press Forging Process To Meet Different Processing Needs.

Choosing The Right Pipe Forging Machine Company (SLS Machinery) To Ensure That You Get The Most Efficient Results When Purchasing A Pipe Forging Machine From A Pipe Forging Machine Company, It Is Important To Compare At Least 3 Companies With Our Pipe Forging Machine Performance Parameters.

Main Application

Packaging & Shipping

Contact Us

4 Rotary Hammers Pipe Swaging Machine | Tube End Forming Machine | Pipe Taper Reducing Swager

Main Technical Parameters Sheet

Brief Introduction on 4 Rotary Hammers Pipe Swaging Machine

4 Rotary Hammers Pipe Swaging Machine | Tube End Forming Machine | Pipe Taper Reducing Swager, Our Machine Is The Best Choice For Designing And Processing Pipe Parts And Can Be Used For A Variety Of Non-Ferrous And Ferrous Materials. It Is Widely Used In Industries Such As Aerospace, Automotive, Medical, Military, Sporting Goods And Home Furnishing Industries To Produce Products. Swaging Is Essentially A Metal Forming Technology That Can Change The Size Of The End Of A Rod, Solid Bar, Or Pipe. Simply Put, Pipe Forging Is The Process Of Changing The Diameter (Taper) Of The Pipe End Through A Mold And A Rotating Hammer.

About Automation Solutions For Pipe Rotary Swaging Presses, SLS Designs And Fully Integrates Solutions To Maximize Efficiency And Reduce Press Operation Costs. SLS Is A Leader In The Metal Forming Industry, With Extensive Experience In Both Professionally Designing New Custom Systems And Retrofitting And Integrating New Systems Around Existing SLS Equipment. We Also Provide Replacement Parts, Tooling, Molds And Rebuild Services For Your Machine. Exceptional Customer Service, Repair/Rebuild Programs And Operator Training Put Our Machines In A Variety Of Applications Around The World. For Any Needs And Questions, Please Feel Free To Contact Us For Help.

Features on 4 Rotary Hammers Pipe Swaging Machine

● High Finish: Because The Finished Product Has A High Finish, Secondary Processing May Not Be Required, Saving Time And Money.

● Quick Assembly: The Taper Can Be Quickly Connected To Various Additional Components, Such As Industrial Pipelines, Auto Parts Axles, Metal Furniture Legs And Other Components.

● Uses Less Material: Material Moves Lengthwise When Hammered Instead Of Being Wastefully Chipped Away.

● Reduced Labor Costs: Easy To Operate And Does Not Require Highly Skilled Operators, Thus Reducing Labor Costs.

● Low Cost And Flexible Tooling: Rotary Press Tooling Is Incredibly Adaptable, And Die Changes Are Simple And Fast.

● Reduced Inventory Requirements: Since Swaging Can Be Done To The Required Size And Surface, There Are Fewer Existing Parts To Maintain.

● Using An Auxiliary Mandrel: The Wall Thickness Can Be Better Controlled During The Entire Press Forging Process To Meet Different Processing Needs.

Choosing The Right Pipe Forging Machine Company (SLS Machinery) To Ensure That You Get The Most Efficient Results When Purchasing A Pipe Forging Machine From A Pipe Forging Machine Company, It Is Important To Compare At Least 3 Companies With Our Pipe Forging Machine Performance Parameters.

Main Application

Packaging & Shipping

Contact Us