+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

We Provide The Most Popular Chamfering Deburring Solution At The Moment: SLS’s EF-120AC Single-Head CNC Chamfering Machine With An Automatic Loading Device, Which Not Only Provides Precise Chamfering Processing, But Also Greatly Improves Efficiency. The SLS EF-120AC Chamfering Machine Has Been The Leading Choice In Its Class For Over 30 Years. Whether You Need To Chamfer Nuts, Studs, Metal Component Edges, Or Other Workpieces, It Delivers Outstanding Results. Chamfers Serve Many Purposes, Including: Removing Sharp Edges To Improve Safety, Allowing For Easier Insertion Or Assembly Of Parts, Improving The Aesthetics Of The Workpiece By Adding Chamfered Edges, Promoting Better Bonding Or Welding In Specific Applications…

_________________________________________________________________________

Model: EF-120C

Specification: Bolts, Nuts, Metal Solid Round Bars, Rods, Tube Edges Chamfering...

Drive Mode: Electric + Hrdraulic

Technical: Cutting And Beveling Machine

Business Type: Professoinal Manufacturer

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 35 Days Dated From Deposit Received

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

EF-120C Type Metal Tube & Solid Bar Chamfer Deburring Equipment | Automatic Feeding Bolt Nut Cutting and Beveling Machine

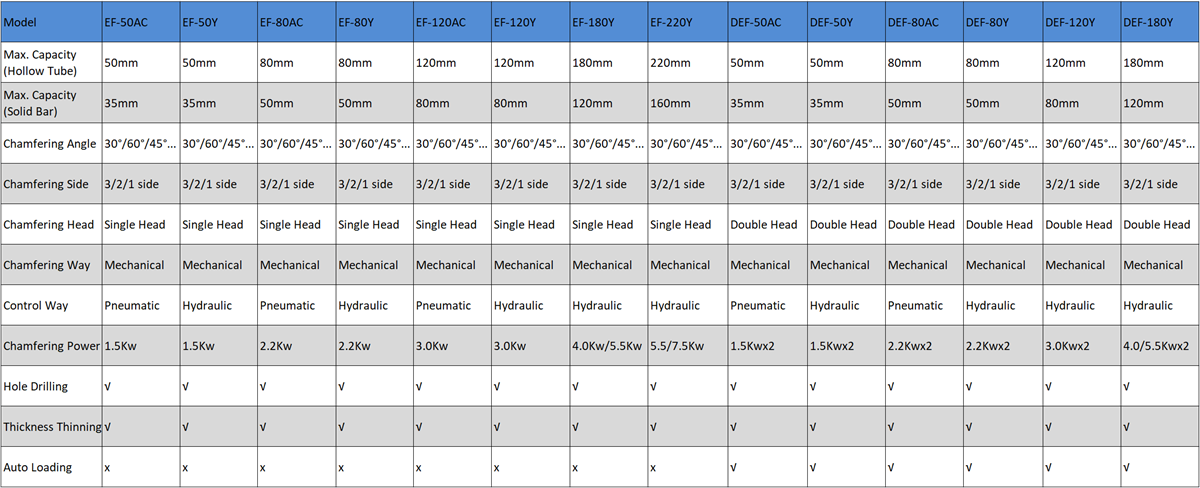

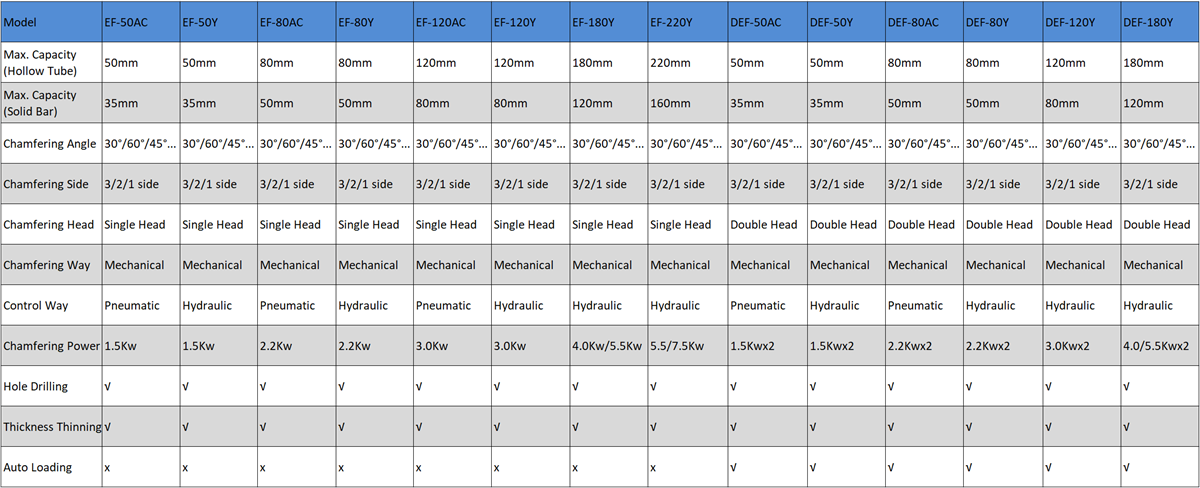

Main Technical Parameters Sheet

Brief Introduction on Automatic Feeding Bolt Nut Cutting and Beveling Machine

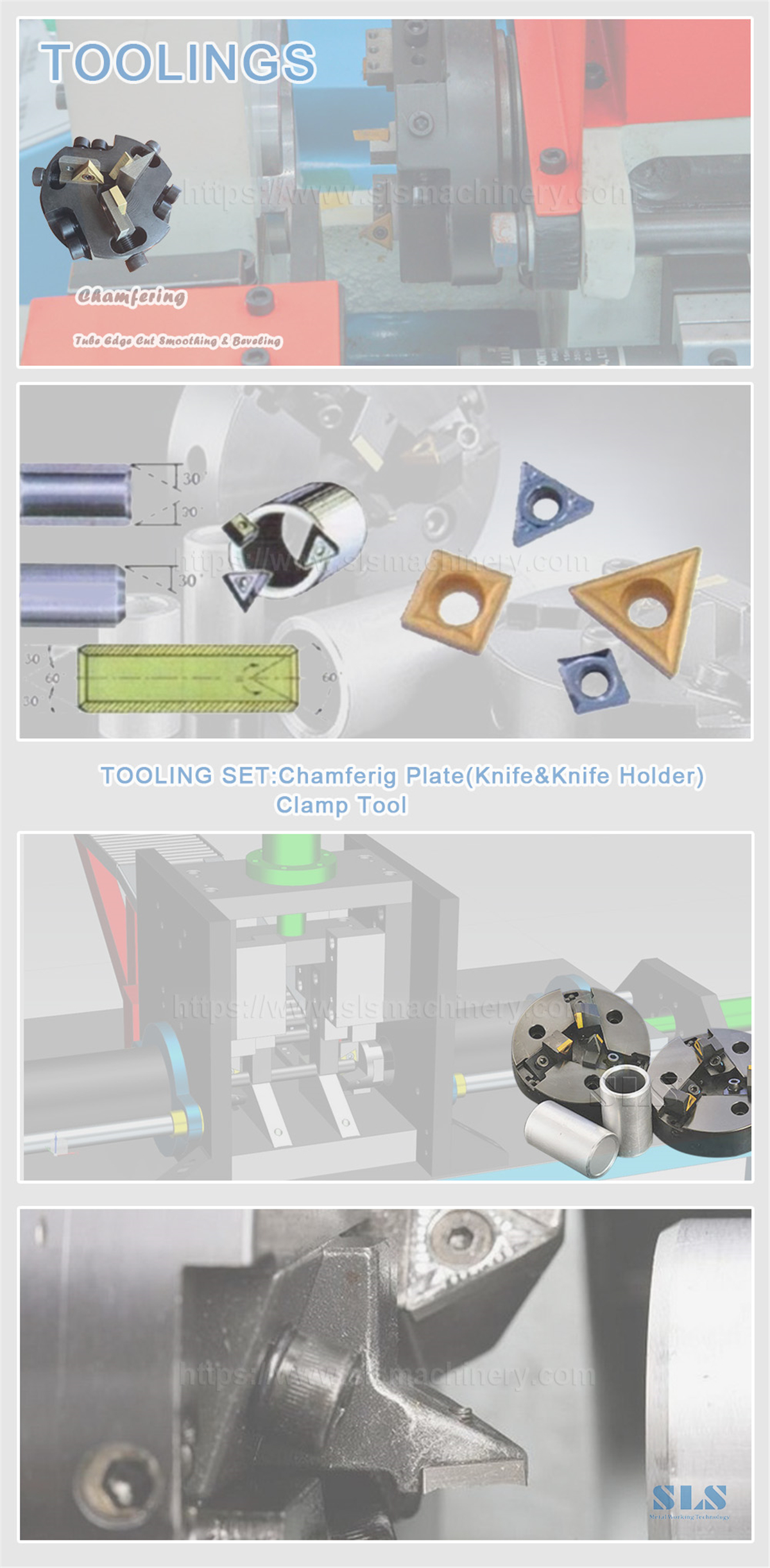

EF-120C Type Metal Tube & Solid Bar Chamfer Deburring Equipment | Automatic Feeding Bolt Nut Cutting And Beveling Machine. Chamfer Tool: Equipped With A Dedicated Chamfer Tool Optimized For Chamfer Applications. This Tool Is Designed To Effectively Remove Material From The Edge Of A Stud, Resulting In A Clean And Well-Defined Chamfered Surface.

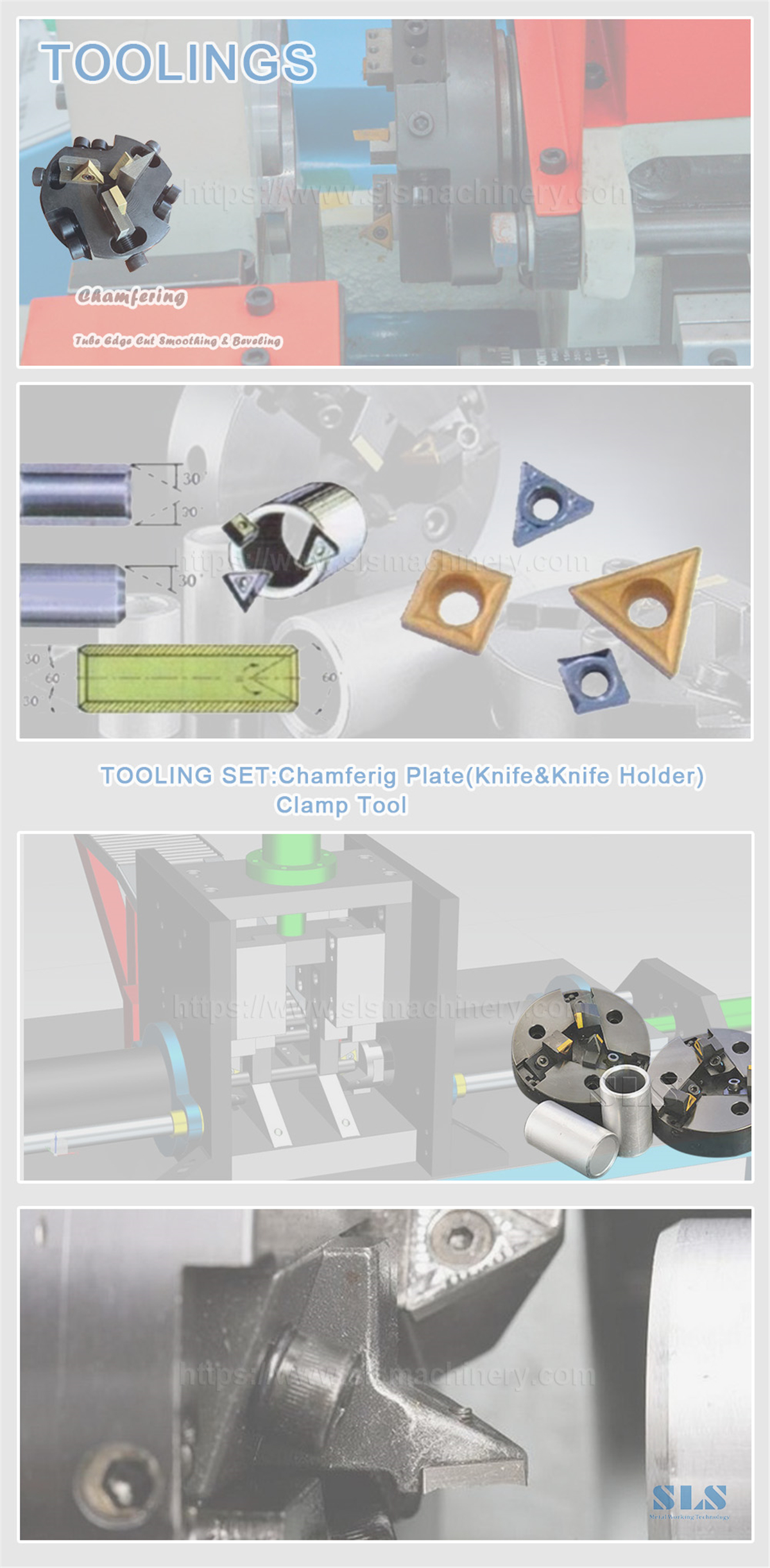

Adjustable Angle: The Machine Can Easily Adjust The Chamfering Angle To Suit Different Requirements. By Rotating The Cutting Tool, You Can Quickly Set The Chamfer Angle To 30° Or 45°, Depending On Your Needs. Diameter Adjustment: Diameter Adjustment Is Available, Allowing You To Match The Appropriate Chamfer Tool Diameter To Stud Size. This Ensures A Precise Fit And Optimal Chamfer Performance.

Reliable Spindle Speed Control: The Ability To Adjust Spindle Speed Using Operator Controls Gives You The Flexibility To Optimize Cutting Speeds For Different Materials And Achieve The Desired Chamfering Results. Precision And Repeatability: Designed To Provide A Consistent And Repeatable Chamfer For Every Stud. Its Precise Cutting Tool Adjustment And Precise Spindle Speed Control Help Achieve Uniform Chamfer Sizes Across Multiple Workpieces.

Operator Controls And Interface: Featuring User-Friendly Operator Controls And An Intuitive Interface, Tool Speed, Chamfer Angle And Other Settings Can Be Easily Adjusted. This Improves User Convenience And Productivity During The Chamfering Process.

If You Have Any Need, Please Contact Us...

Features on Automatic Feeding Bolt Nut Cutting and Beveling Machine

● Control Panel Offers Easy Access to Auto and Manual Operating Modes.

● Equipped with Emergency Stop Device.

● All The Parts Are Made Under Very Strict Quality Control, So The Quality of Machine Is In High Level and The Specification Is Standardized.

● Chamfering Work Is Driven By Mechanical and Clamping Work Driven By Hydraulic.

● A Circular Tube Modifies An Interior Angle, An External Angle and Flat Plane At One Time with Fastness and Precision.

● Automatic and Manual Working Mode Which Are Convenient for Adjusting The Machine, Mold and Chamfering Knife.

● Material Available: Carbon Steel, Stainless Steel, Copper, Aluminum...

● Clamp Device and Knife Holder Are Precisely Designed for Ensure The Center Line Between Workpiece and Knife Holder At The Same Level.

● Dual Feed Chamfer System:

First Speed------Fast Forward Movement Nearly to Tube End to Save The Time.

Second Speed---Infinitely Variable Forward Adjustable Chamfering Speed to Get Smooth Finish.

● Foot Pedal Cycle Start.

● The Design of The Tooling Help Customer Easy to Change.

● Optional: Double Head Can Be Added to The Machine Based on Detailed Chamfering Requirement.

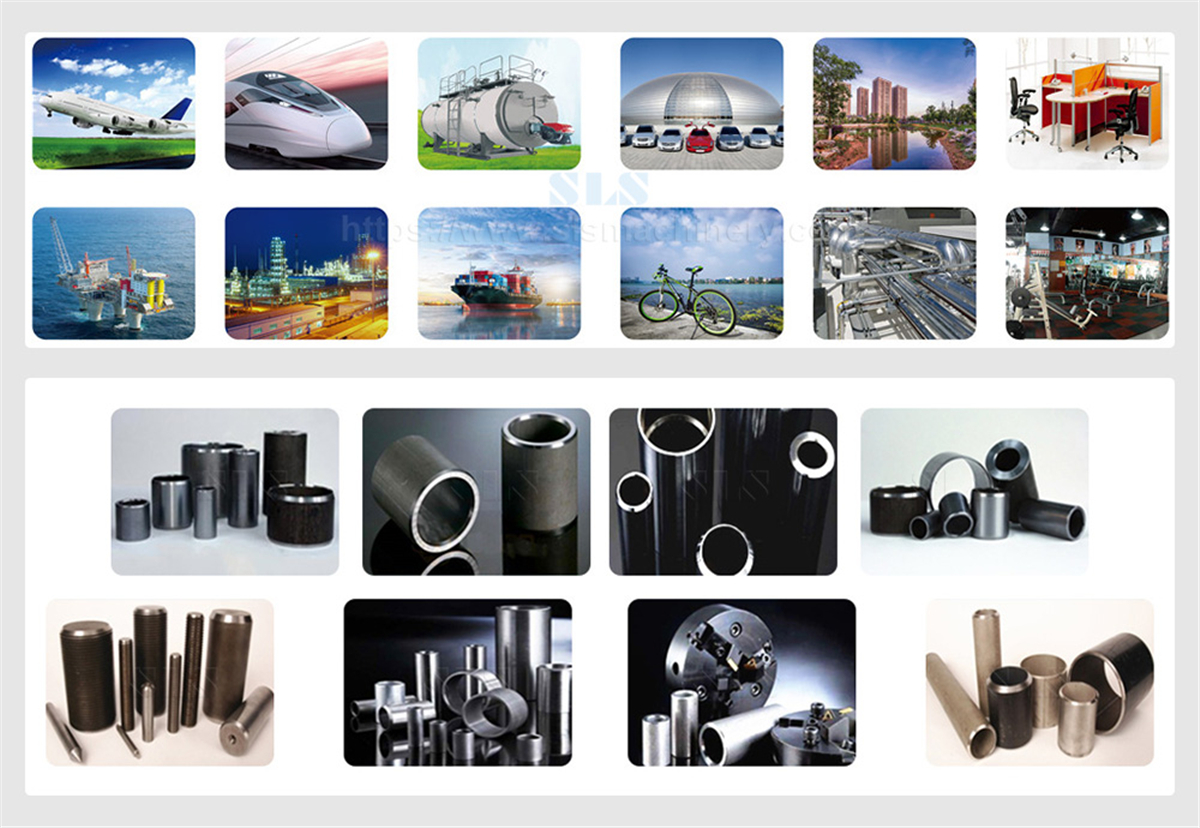

Main Application

Packaging & Shipping

Contact Us

EF-120C Type Metal Tube & Solid Bar Chamfer Deburring Equipment | Automatic Feeding Bolt Nut Cutting and Beveling Machine

Main Technical Parameters Sheet

Brief Introduction on Automatic Feeding Bolt Nut Cutting and Beveling Machine

EF-120C Type Metal Tube & Solid Bar Chamfer Deburring Equipment | Automatic Feeding Bolt Nut Cutting And Beveling Machine. Chamfer Tool: Equipped With A Dedicated Chamfer Tool Optimized For Chamfer Applications. This Tool Is Designed To Effectively Remove Material From The Edge Of A Stud, Resulting In A Clean And Well-Defined Chamfered Surface.

Adjustable Angle: The Machine Can Easily Adjust The Chamfering Angle To Suit Different Requirements. By Rotating The Cutting Tool, You Can Quickly Set The Chamfer Angle To 30° Or 45°, Depending On Your Needs. Diameter Adjustment: Diameter Adjustment Is Available, Allowing You To Match The Appropriate Chamfer Tool Diameter To Stud Size. This Ensures A Precise Fit And Optimal Chamfer Performance.

Reliable Spindle Speed Control: The Ability To Adjust Spindle Speed Using Operator Controls Gives You The Flexibility To Optimize Cutting Speeds For Different Materials And Achieve The Desired Chamfering Results. Precision And Repeatability: Designed To Provide A Consistent And Repeatable Chamfer For Every Stud. Its Precise Cutting Tool Adjustment And Precise Spindle Speed Control Help Achieve Uniform Chamfer Sizes Across Multiple Workpieces.

Operator Controls And Interface: Featuring User-Friendly Operator Controls And An Intuitive Interface, Tool Speed, Chamfer Angle And Other Settings Can Be Easily Adjusted. This Improves User Convenience And Productivity During The Chamfering Process.

If You Have Any Need, Please Contact Us...

Features on Automatic Feeding Bolt Nut Cutting and Beveling Machine

● Control Panel Offers Easy Access to Auto and Manual Operating Modes.

● Equipped with Emergency Stop Device.

● All The Parts Are Made Under Very Strict Quality Control, So The Quality of Machine Is In High Level and The Specification Is Standardized.

● Chamfering Work Is Driven By Mechanical and Clamping Work Driven By Hydraulic.

● A Circular Tube Modifies An Interior Angle, An External Angle and Flat Plane At One Time with Fastness and Precision.

● Automatic and Manual Working Mode Which Are Convenient for Adjusting The Machine, Mold and Chamfering Knife.

● Material Available: Carbon Steel, Stainless Steel, Copper, Aluminum...

● Clamp Device and Knife Holder Are Precisely Designed for Ensure The Center Line Between Workpiece and Knife Holder At The Same Level.

● Dual Feed Chamfer System:

First Speed------Fast Forward Movement Nearly to Tube End to Save The Time.

Second Speed---Infinitely Variable Forward Adjustable Chamfering Speed to Get Smooth Finish.

● Foot Pedal Cycle Start.

● The Design of The Tooling Help Customer Easy to Change.

● Optional: Double Head Can Be Added to The Machine Based on Detailed Chamfering Requirement.

Main Application

Packaging & Shipping

Contact Us