+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

SLS Machinery’s 76 Type CNC-4A-2S CNC Precision Pipe Bending Machine | Tube Bends Form Solutions - Frame Chassis Square Tubular Automated Bender ( Multidimensional and automated bending of tubes). Highly efficient automatic bending technology for small and big bending tasks with the greatest precision. Our fully automated solutions mean optimum cycle times and large production volumes. The outstanding flexibility of our advanced CNC tube bending machines gives you economical bending process and meets the most demanding requirements. If you are looking for a suitable pipe bending machine, then contacting us is definitely the right thing to do...

_________________________________________________________________________

Model: 76CNC-4A-2S

Specification: Square Rectangle Profile - Wall Thickness ≤4mm

Drive Mode: CNC Electric ( Automated Bending )

Suit Bending: Multidimensional and automated bending

Business Type: Professoinal Manufacturer

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 45 Days Dated From Deposit Received

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

76 Type CNC-4A-2S CNC Precision Pipe Bending Machine | Tube Bends Form Solutions - Frame Chassis Square Tubular Automated Bender

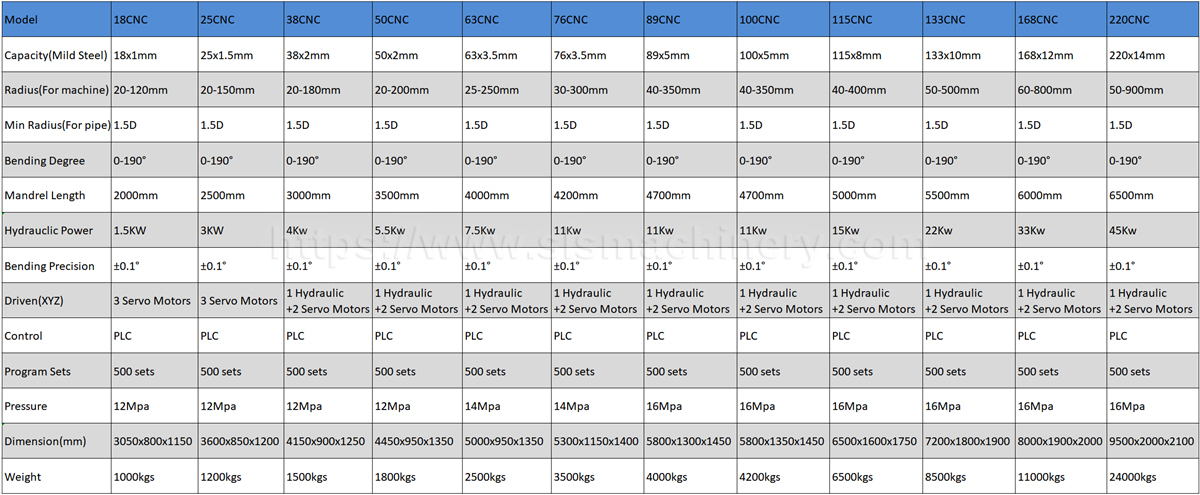

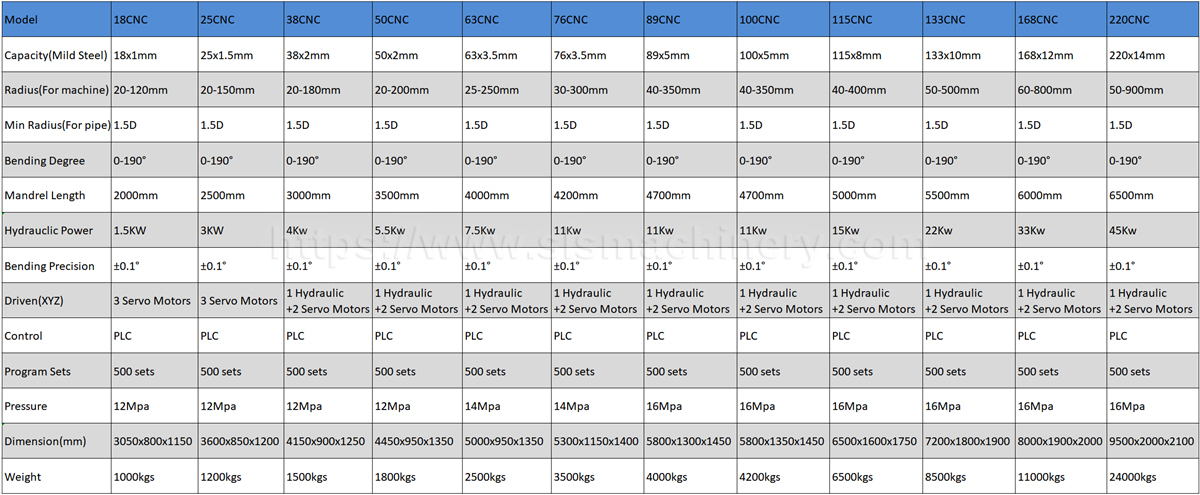

Main Technical Parameters Sheet

Brief Introduction on Frame Chassis Square Tubular Automated Bender

SLS Machinery’s 76 Type CNC-4A-2S CNC Precision Pipe Bending Machine | Tube Bends Form Solutions - Frame Chassis Square Tubular Automated Bender are designed for both general and precision bending applications in a wide variety of industries such as HVAC, aerospace, automotive, and furniture. Our precision CNC tube bending machines will save you money by providing maximum flexibility while offering the latest in features and advanced technology.

CNC benders can be used as stand along machines or building blocks to create a fully automated fabrication cell. All machines can be coupled to auto loaders with weld-seam detectors and unloaders for lean operations.

Precision CNC Tube Bending is well known throughout the industry for excelling in "tough" automated pipe bending solutions such as:

• Thin Wall Tube Bending eg. 3 1/2" O.D. .012" Wall

• Tight Radius 1D (1 Diameter) Tube Bends ... and less!

• Large Diameter Tube Bends to 10 inch Diameter ... and more!

• Small Diameter Tube Bends from 1/32" Diameter

• Tube in a Tube Bends and Assembly

• Square pipe bending characteristics, - more infomation contact us...

• Other complex Tube Fabrication

Please contact us! The Precision Tube Bending Team of experienced and dedicated employees is ready to serve you for all of your tube bending and tube fabrication needs. Let us demonstrate what we can do to earn your business.

4A-2S:

Bending (Y-Axis): Controlled by Servomotor.

Feeding (X-Axis): Controlled by Servomotor.

Rotating (Z-Axis): Controlled by Servomotor.

Machine Head movement: Controlled by Servomotor.

2-Layer bending mold to achieve different bending radii.

Features on Frame Chassis Square Tubular Automated Bender

● Standard Clockwise Bending Direction.

● Interactive PLC Touch Screen Offers Easy Access to Auto And Manual Operating Modes.

● System Diagnostics and Multiple Language Capability.

● Obtain Quality Repeatable Bends In Steel, Stainless, Aluminum, Titanium and Brass.

● Maximum 500 Sets of Program Storage,Maximum 32 Bends for Each Program.

● With Independent Programmable Speeds on Y, B(By Electrical Adjust) and C Axis(By Oil Flow Adjust).

● Bending Axis-Driven by Cylinder,Feeding Axis-Driven by Servo Motor,Rotating Axis-Driven by Servo Motor.

● One Set of Tooling for Draw Bending.

● With Air Cooling System or Water Cooling System.

● Electric: As Required (3 Phase 220V or 380V or 415V...).

● CE & RD & OEM & ODM and More Support ...

Main Application

Packaging & Shipping

Contact Us

76 Type CNC-4A-2S CNC Precision Pipe Bending Machine | Tube Bends Form Solutions - Frame Chassis Square Tubular Automated Bender

Main Technical Parameters Sheet

Brief Introduction on Frame Chassis Square Tubular Automated Bender

SLS Machinery’s 76 Type CNC-4A-2S CNC Precision Pipe Bending Machine | Tube Bends Form Solutions - Frame Chassis Square Tubular Automated Bender are designed for both general and precision bending applications in a wide variety of industries such as HVAC, aerospace, automotive, and furniture. Our precision CNC tube bending machines will save you money by providing maximum flexibility while offering the latest in features and advanced technology.

CNC benders can be used as stand along machines or building blocks to create a fully automated fabrication cell. All machines can be coupled to auto loaders with weld-seam detectors and unloaders for lean operations.

Precision CNC Tube Bending is well known throughout the industry for excelling in "tough" automated pipe bending solutions such as:

• Thin Wall Tube Bending eg. 3 1/2" O.D. .012" Wall

• Tight Radius 1D (1 Diameter) Tube Bends ... and less!

• Large Diameter Tube Bends to 10 inch Diameter ... and more!

• Small Diameter Tube Bends from 1/32" Diameter

• Tube in a Tube Bends and Assembly

• Square pipe bending characteristics, - more infomation contact us...

• Other complex Tube Fabrication

Please contact us! The Precision Tube Bending Team of experienced and dedicated employees is ready to serve you for all of your tube bending and tube fabrication needs. Let us demonstrate what we can do to earn your business.

4A-2S:

Bending (Y-Axis): Controlled by Servomotor.

Feeding (X-Axis): Controlled by Servomotor.

Rotating (Z-Axis): Controlled by Servomotor.

Machine Head movement: Controlled by Servomotor.

2-Layer bending mold to achieve different bending radii.

Features on Frame Chassis Square Tubular Automated Bender

● Standard Clockwise Bending Direction.

● Interactive PLC Touch Screen Offers Easy Access to Auto And Manual Operating Modes.

● System Diagnostics and Multiple Language Capability.

● Obtain Quality Repeatable Bends In Steel, Stainless, Aluminum, Titanium and Brass.

● Maximum 500 Sets of Program Storage,Maximum 32 Bends for Each Program.

● With Independent Programmable Speeds on Y, B(By Electrical Adjust) and C Axis(By Oil Flow Adjust).

● Bending Axis-Driven by Cylinder,Feeding Axis-Driven by Servo Motor,Rotating Axis-Driven by Servo Motor.

● One Set of Tooling for Draw Bending.

● With Air Cooling System or Water Cooling System.

● Electric: As Required (3 Phase 220V or 380V or 415V...).

● CE & RD & OEM & ODM and More Support ...

Main Application

Packaging & Shipping

Contact Us