+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

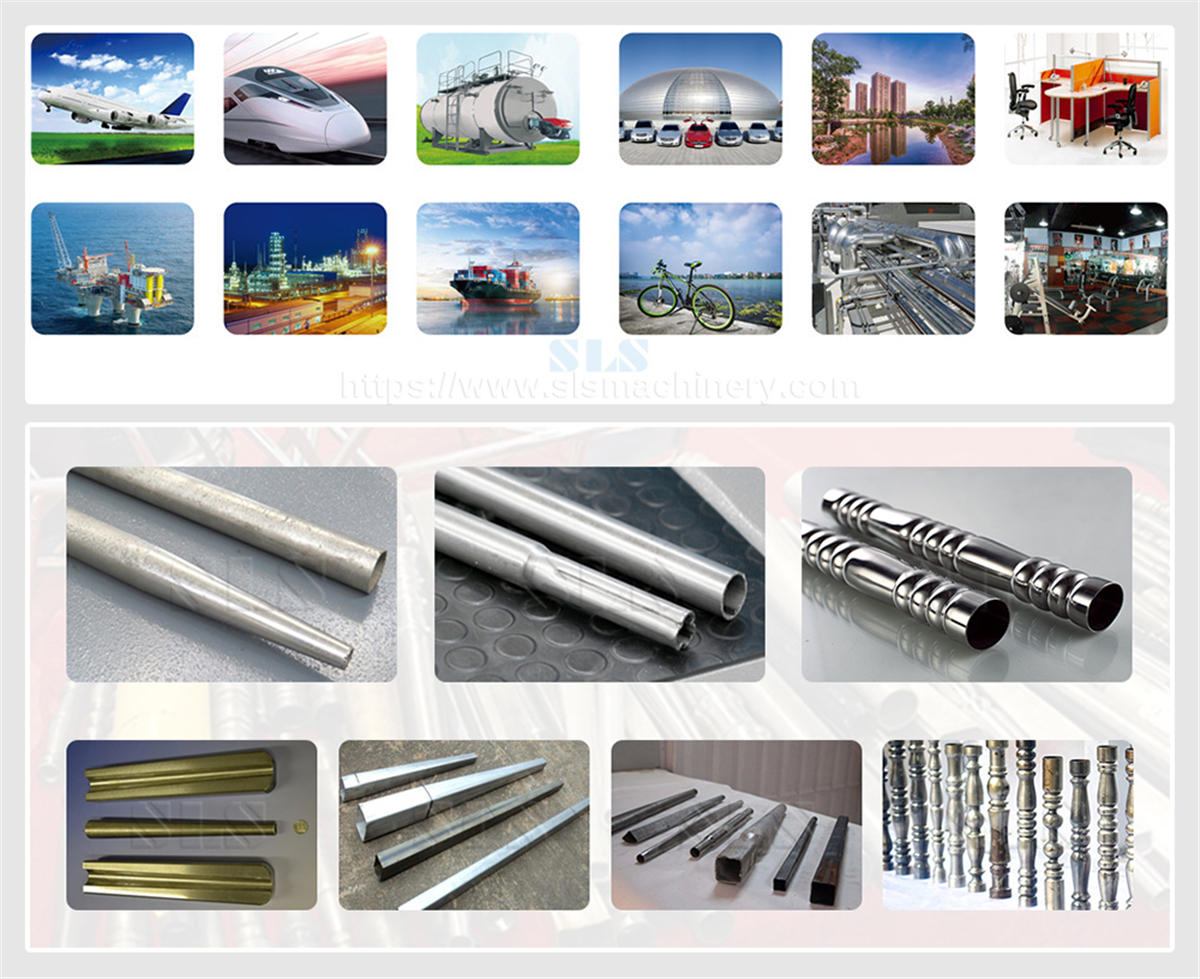

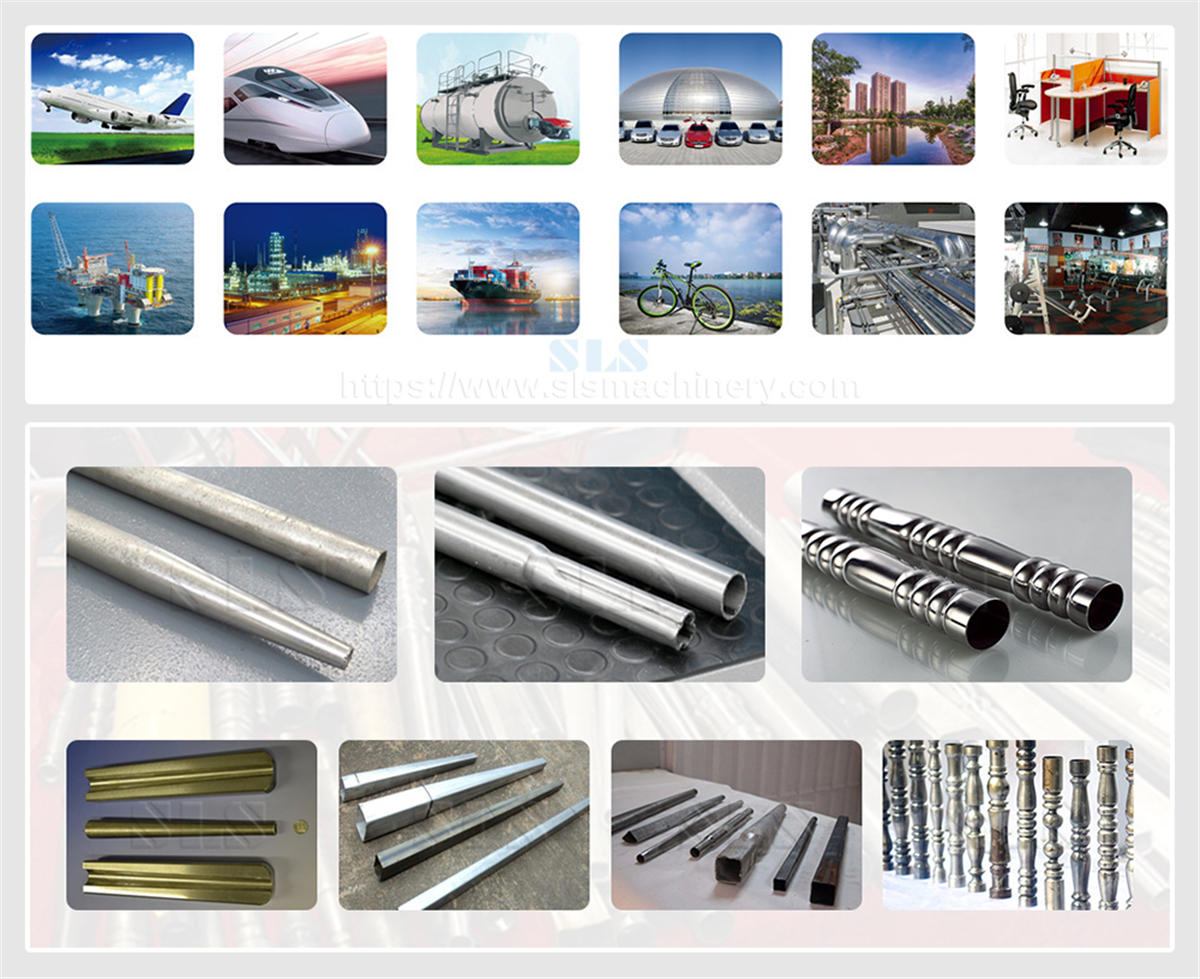

Our TF-50F Type Manual Cone Pipe Cold Forming Tube Swaging Machine Is Used In The Manufacture of Various Parts for The Automotive, Aerospace,Defense Industries and Furniture Industries and Many More By Providing Solutions Which Maximize The Quality and Production Efficiency. For Example, In The Production of Pipes, Hollow Steering Columns, Drive and Guide Shafts,Table Legs&Chair Legs as Well as Various Fasteners.

_________________________________________________________________________

Model: TF-50F

Specification: 50mm(2")x1.5mm

Drive Mode: Mechanical

Technical: Cold Forming

Business Type: Professoinal Manufacture

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 20 Days Dated From Deposit Received

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

TF-50F Type Manual Cone Pipe Cold Forming Tube Swaging Machine

Main Technical Parameters Sheet

Brief Introduction on Manual Cone Pipe Cold Forming Tube Swaging Machine

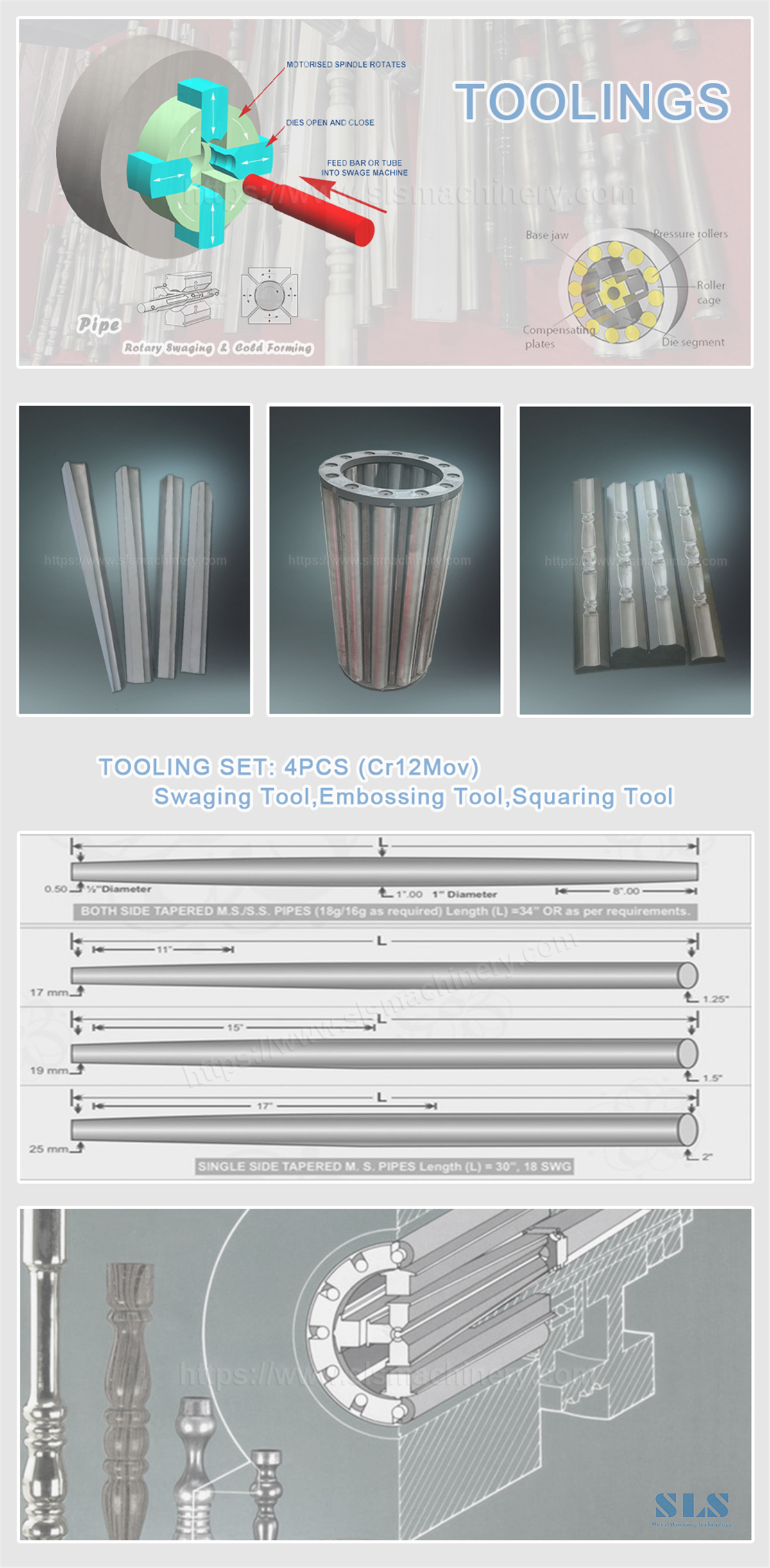

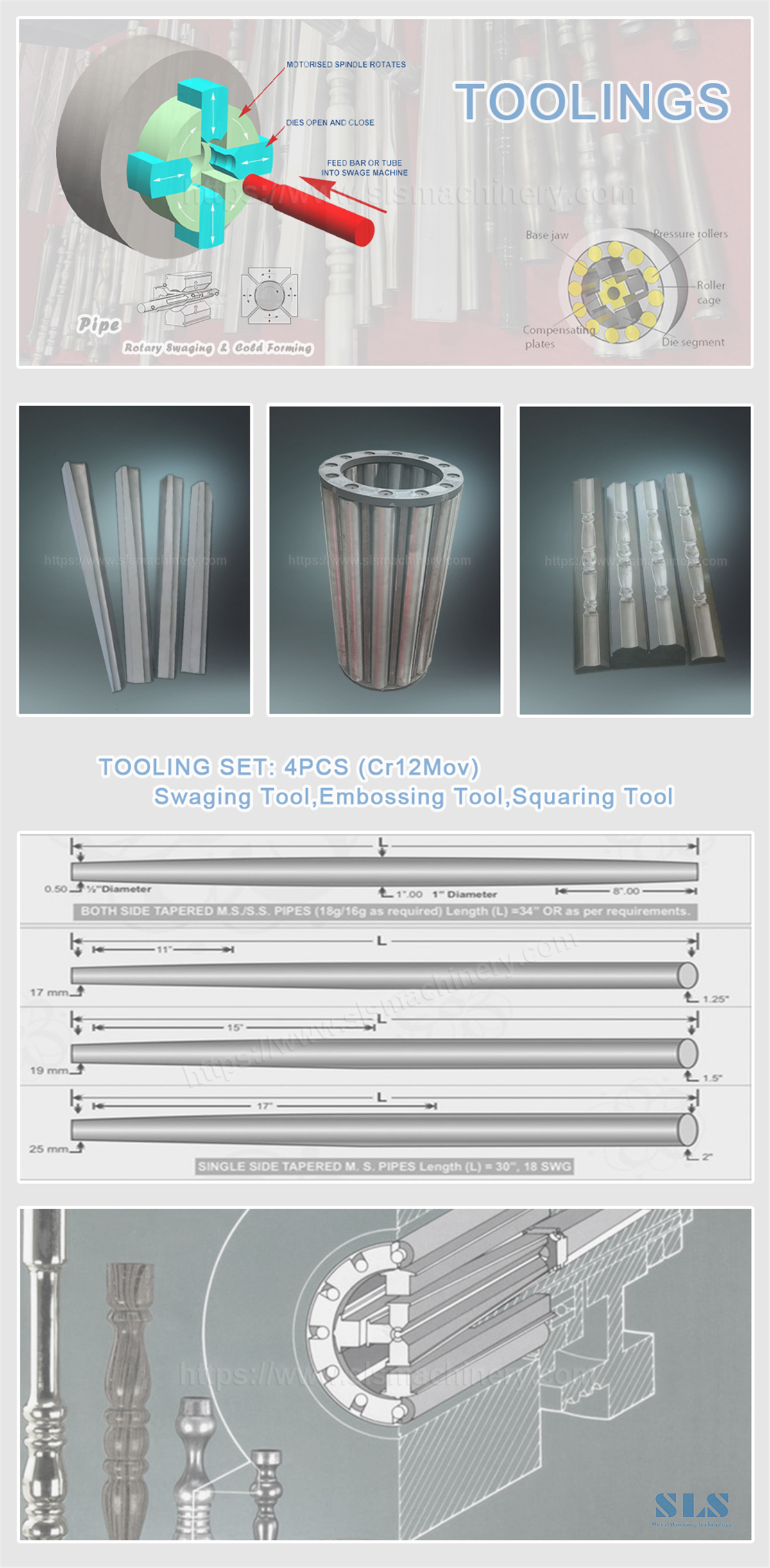

SLS TF-50F Type Manual Cone Pipe Cold Forming Tube Swaging Machine Is a Special Kind of Tube Cold Tapering Machine. In Other Words, Rotary Swaging Is Designed As a Cost-efficient Alternative to Traditional Metal Forging and Machining Operations. The Function By Using Four Die Rotary Hammering Mechanisms to Taper a Tube to Its Final Form. As The Tube Is Fed Into The Machine, It Will Be Swaged By The Dies To Taper It Into The Desired Form, Which Will Be Set According to The Specifications On The Control Mechanism. By Applying German Advanced Technology and Good Mechanism & Electrical Quality Controlling, Machine with Extremely Advantage of Low Noise.

Choose From a Manual, Semi-automatic, or Automatic Pipe Tapering Machine to Best Meet Your Level of Production.

Features on Hand Operated Metal Tube Pipe Swaging Machine

● Operation Panel Offers Easy Operation of Machine.

● All The Parts Are Made Under Very Strict Quality Control, So The Quality of Machine is In High Level and The Specification is Standardized.

● Machine Featured As Manual Pipe Loading, Manual Pipe Feeding Into Machine, Automatic Rotary Swaging.

● A High Quality Shaping Will Use Tools That Move The Dies In and Out, Offering as Many as 3000 Blows Per Minute to Hammer The Tube Into The Desired Shape.

● The Thickness of The Pipe and The Strength of The Material to Be Tapered Will Also Impact How The Materials Should be Prepared to Create a Clean Tapered Edge.

● Available Pipe Material: Steel, Stainless, Aluminum, Titanium and Brass...

● The Design of The Tooling Help Customer Easy to Change.

● Very Low Loise During Working: 75-85db.

● CE&ISO 9001:2000.

Main Application

Packaging & Shipping

Contact Us

TF-50F Type Manual Cone Pipe Cold Forming Tube Swaging Machine

Main Technical Parameters Sheet

Brief Introduction on Manual Cone Pipe Cold Forming Tube Swaging Machine

SLS TF-50F Type Manual Cone Pipe Cold Forming Tube Swaging Machine Is a Special Kind of Tube Cold Tapering Machine. In Other Words, Rotary Swaging Is Designed As a Cost-efficient Alternative to Traditional Metal Forging and Machining Operations. The Function By Using Four Die Rotary Hammering Mechanisms to Taper a Tube to Its Final Form. As The Tube Is Fed Into The Machine, It Will Be Swaged By The Dies To Taper It Into The Desired Form, Which Will Be Set According to The Specifications On The Control Mechanism. By Applying German Advanced Technology and Good Mechanism & Electrical Quality Controlling, Machine with Extremely Advantage of Low Noise.

Choose From a Manual, Semi-automatic, or Automatic Pipe Tapering Machine to Best Meet Your Level of Production.

Features on Hand Operated Metal Tube Pipe Swaging Machine

● Operation Panel Offers Easy Operation of Machine.

● All The Parts Are Made Under Very Strict Quality Control, So The Quality of Machine is In High Level and The Specification is Standardized.

● Machine Featured As Manual Pipe Loading, Manual Pipe Feeding Into Machine, Automatic Rotary Swaging.

● A High Quality Shaping Will Use Tools That Move The Dies In and Out, Offering as Many as 3000 Blows Per Minute to Hammer The Tube Into The Desired Shape.

● The Thickness of The Pipe and The Strength of The Material to Be Tapered Will Also Impact How The Materials Should be Prepared to Create a Clean Tapered Edge.

● Available Pipe Material: Steel, Stainless, Aluminum, Titanium and Brass...

● The Design of The Tooling Help Customer Easy to Change.

● Very Low Loise During Working: 75-85db.

● CE&ISO 9001:2000.

Main Application

Packaging & Shipping

Contact Us