+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Precision Engineered for Automotive Excellence: The SLS Fully Automatic Double-End Pipe Forming MachineAt SLS Machinery, we deliver cutting-edge manufacturing solutions designed for the stringent demands of the modern automotive industry. Our flagship Fully Automatic, Dual Hydraulic, 3-Station Tube End Forming Machine embodies this commitment, setting a new standard for efficiency, precision, and reliability in the production of automotive fluid system components. This advanced pipe double end forming machine is engineered to perform complex expanding and reducing operations on both ends of a pipe simultaneously. It is the ideal core equipment for manufacturers of automotive pipe fittings, seeking to achieve unparalleled production quality and throughput…

_________________________________________________________________________

Model: DTM-100CNC-3S

Specification: 125mm(5")x3.0mm

Drive Mode: Mechanical & Hydraulic & Electric

Technical: Press( Forming - Tube End Expaning & Shrinking )

Business Type: Professoinal Manufacturer

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 45 Days Dated From Deposit Received

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

Fully Automatic CNC Double Heads Tube End Forming Machine 3 Station for Automotive Pipe Fittings | SLS Machinery ( DTM-100CNC-3S )

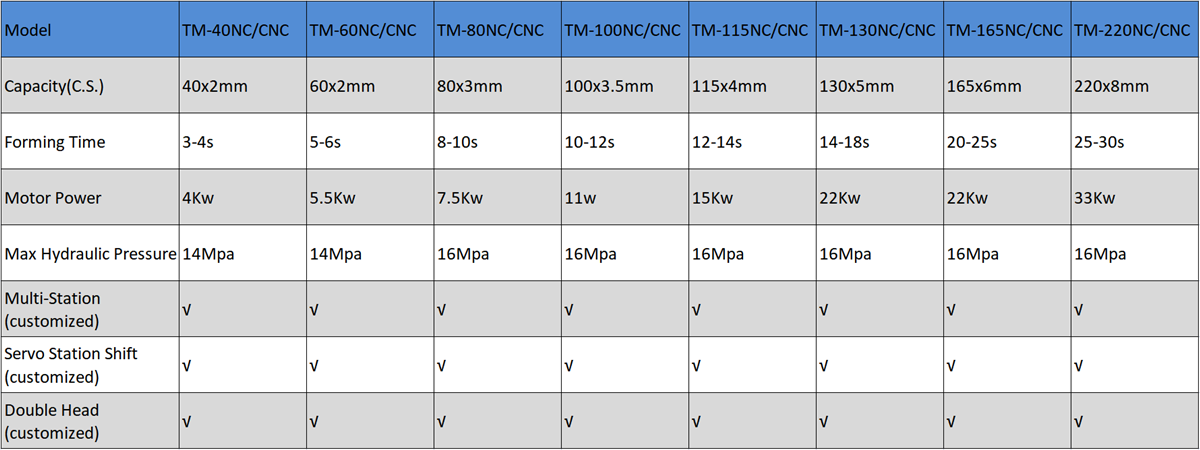

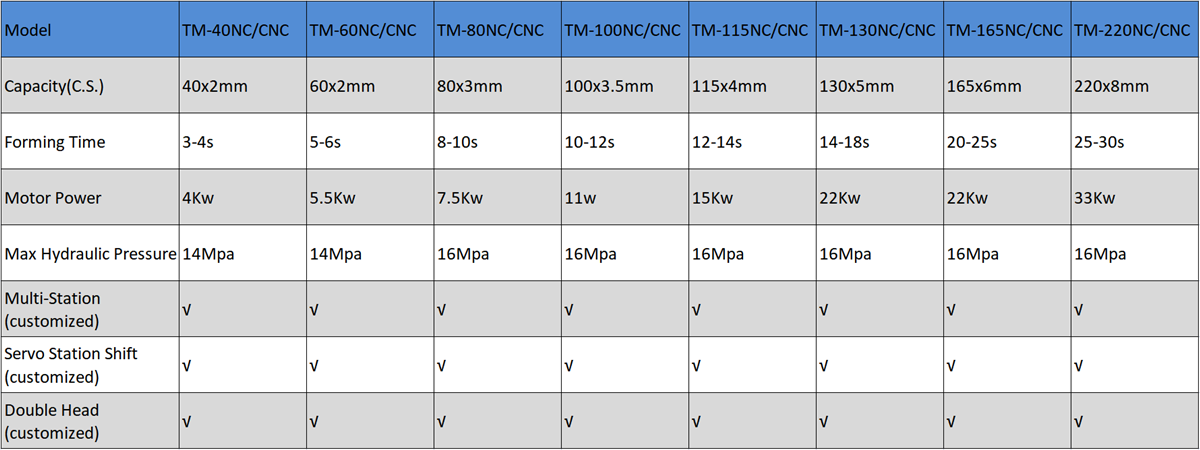

Main Technical Parameters Sheet

Brief Introduction on Fully Automatic CNC Double Heads Tube End Forming Machine

Our high-performance, fully automatic double heads tube end forming machine designed for high-volume manufacturing. This pipe double end forming machine processes both ends of automotive pipes (fuel, brake, AC pipes) simultaneously, doubling your production efficiency and ensuring consistent, high-precision results.

Dual Hydraulic System for Maximum Output:

Experience a near 100% increase in production efficiency. Our machine features two completely independent hydraulic stations, powering a double heads tube end former that processes both pipe ends at once, eliminating sequential processing delays.

Three-Station Precision Forming Process:

Achieve complex geometries with flawless quality. Each end is processed through three dedicated stations in a "Two-Expansion, One-Reduction" sequence. This Three Workstations pipe end forming machine design ensures superior forming quality, reduces stress on materials, and extends tooling life, making it perfect for intricate automotive pipe fittings end forming.

CNC Fully Automated Operation:

Enable "lights-out" production with our integrated robotic loading and unloading system. This automation minimizes manual intervention, ensures consistent cycle times, and significantly reduces labor costs and operational errors.

As a professional manufacturer of tube end forming equipment, SLS Machinery is committed to providing customers with expertly crafted, high-performance tube end processing solutions, safeguarding pipeline connections across various industries with professional manufacturing capabilities.

Features on Fully Automatic CNC Double Heads Tube End Forming Machine

● Equipped with Emergency Stop Device.

● Touch Screen or Human Interface Offers Easy Access to Auto and Manual Operating Modes.

● Suitable for The Expanding for Various Metal Pipes with Different Material and Different Shape.

● Both Manual and Automatic Operations Are Available.

● Tube Clamping and End Forming Driven by Hydraulic.

● Forming Shapes Can Be Convex, Concave, Sectional, Long & Flat, Square, V-Shape, Open Elbow, Flat Elbow...Etc.

● The Design of The Tooling Varies with Work-Piece & Customers Requirements.

● The Design of The Tooling Help Customer Easy to Change.

● All The Parts Are Made Under Very Strict Quality Control, So The Quality of Machine Is In High Level and The Specification Is Standardized.

● Water or Fan Cooling System Ensures The Equipment Long-Time Work Stably Under The High Temperature.

● Foot Pedal Cycle Start.

● Optional:Multi Station Can Be Added to The Machine Based on Detailed Forming Requirement.

● Optional: Double Head Can Be Added to The Machine Based on Detailed Forming Requirement.

● Optional: Multi Station Shifting Can Be Chosen As Servo(Electrical) or Hydraulic Control.

● Optional:An Additional Feeding System Can Be Added to The Machine. The Operating Security Is Greatly Increased Because The Operators Just Do The Unloading & Collecting Job of Finished Pipes.

Main Application

Packaging & Shipping

Contact Us

Fully Automatic CNC Double Heads Tube End Forming Machine 3 Station for Automotive Pipe Fittings | SLS Machinery ( DTM-100CNC-3S )

Main Technical Parameters Sheet

Brief Introduction on Fully Automatic CNC Double Heads Tube End Forming Machine

Our high-performance, fully automatic double heads tube end forming machine designed for high-volume manufacturing. This pipe double end forming machine processes both ends of automotive pipes (fuel, brake, AC pipes) simultaneously, doubling your production efficiency and ensuring consistent, high-precision results.

Dual Hydraulic System for Maximum Output:

Experience a near 100% increase in production efficiency. Our machine features two completely independent hydraulic stations, powering a double heads tube end former that processes both pipe ends at once, eliminating sequential processing delays.

Three-Station Precision Forming Process:

Achieve complex geometries with flawless quality. Each end is processed through three dedicated stations in a "Two-Expansion, One-Reduction" sequence. This Three Workstations pipe end forming machine design ensures superior forming quality, reduces stress on materials, and extends tooling life, making it perfect for intricate automotive pipe fittings end forming.

CNC Fully Automated Operation:

Enable "lights-out" production with our integrated robotic loading and unloading system. This automation minimizes manual intervention, ensures consistent cycle times, and significantly reduces labor costs and operational errors.

As a professional manufacturer of tube end forming equipment, SLS Machinery is committed to providing customers with expertly crafted, high-performance tube end processing solutions, safeguarding pipeline connections across various industries with professional manufacturing capabilities.

Features on Fully Automatic CNC Double Heads Tube End Forming Machine

● Equipped with Emergency Stop Device.

● Touch Screen or Human Interface Offers Easy Access to Auto and Manual Operating Modes.

● Suitable for The Expanding for Various Metal Pipes with Different Material and Different Shape.

● Both Manual and Automatic Operations Are Available.

● Tube Clamping and End Forming Driven by Hydraulic.

● Forming Shapes Can Be Convex, Concave, Sectional, Long & Flat, Square, V-Shape, Open Elbow, Flat Elbow...Etc.

● The Design of The Tooling Varies with Work-Piece & Customers Requirements.

● The Design of The Tooling Help Customer Easy to Change.

● All The Parts Are Made Under Very Strict Quality Control, So The Quality of Machine Is In High Level and The Specification Is Standardized.

● Water or Fan Cooling System Ensures The Equipment Long-Time Work Stably Under The High Temperature.

● Foot Pedal Cycle Start.

● Optional:Multi Station Can Be Added to The Machine Based on Detailed Forming Requirement.

● Optional: Double Head Can Be Added to The Machine Based on Detailed Forming Requirement.

● Optional: Multi Station Shifting Can Be Chosen As Servo(Electrical) or Hydraulic Control.

● Optional:An Additional Feeding System Can Be Added to The Machine. The Operating Security Is Greatly Increased Because The Operators Just Do The Unloading & Collecting Job of Finished Pipes.

Main Application

Packaging & Shipping

Contact Us