+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Our D.TF-50CNC Taper Processing Of Mountain Bike Straight Handlebars | Tube Both Ends Forming | Pipe Swaging Production Line Is Suitable For Various Handlebar Taper Forming. Simply Put, It Is A Machine For Taper Forming Of Metal Tube Ends. The Principle Is To Achieve Compression Taper Forming Through The Rapid Blows Of Rotating Hammers And Dies. The Integrated Configuration Of The Fully Automatic Loading And Unloading System Can Realize Efficient And Automatic Processing Of Workpieces, Significantly Improving Production Efficiency And Precision. This Equipment Is Widely Used In Bicycles, Motorcycles, Automobiles, Furniture, Medical, Aerospace And Other Industries. It Is An Indispensable And Efficient Intelligent Equipment In Modern Manufacturing…

_________________________________________________________________________

Model: D. TF-50CNC

Specification: 50mm(2")x2.0mm

Drive Mode: Mechanical & Hydraulic

Technical: Tube Both Ends Reduction / Tapered Forming

Business Type: Professoinal Manufacturer

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 35 Days Dated From Deposit Received

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

Taper Processing of Mountain Bike Straight Handlebars | Tube Both Ends Forming | Pipe Swaging Production Line

Main Technical Parameters Sheet

Brief Introduction on Tube Both Ends Forming | Pipe Swaging Production Line

Mountain Bike Straight Handlebars, Also Known As Flat Handlebars, Are A Popular Choice For Riders Seeking A More Upright Riding Position And Increased Control On Technical Terrain. The Handlebar Is A Metal Tube With Tapered Ends, With The Following Common Sizes: 31.8mm, 22.2mm, 25.4mm, 23.6mm (Tube Diameter Reduced).

How To Efficiently Produce Bicycle Straight Handlebars, Or What Kind Of Machine Can Be Selected To Produce High-Precision Straight Handlebars?

The SLS Machine's Tube Taper Forming At Both Ends - Automatic Loading And Unloading Production Line Can Efficiently And Conveniently Complete The One-Time Forming Of The Taper At Both Ends Of The Mountain Bike Straight Handlebar With High Precision.

SLS Machinery Is A Professional Manufacturer Of Metal Tube Processing, Ranging From Simple To Complex CNC Machines: Tube Bending Machines, Tube Cutting Machines, Tube End Forming Machines (Cone Tube Machines, Tube Embossing Machines, Tube Square Machines), Chamfering Machines And Other Automated Tube Processing Machines.

Professional Engineers Are Committed To Providing Complete One-Stop Solutions In The Field Of Metal Tube Processing And Customized Market Needs. Please Contact Us For More Information...

Features on Tube Both Ends Forming | Pipe Swaging Production Line

● Taper Processing of Mountain Bike Straight Handlebars.

● High Finish: Because The Finished Product Has A High Finish, Secondary Processing May Not Be Required, Saving Time And Money.

● Quick Assembly: The Taper Can Be Quickly Connected To Various Additional Components, Such As Industrial Pipelines, Auto Parts Axles, Metal Furniture Legs And Other Components.

● Reduced Inventory Requirements: Since Swaging Can Be Done To The Required Size And Surface, There Are Fewer Existing Parts To Maintain.

● Uses Less Material: Material Moves Lengthwise When Hammered Instead Of Being Wastefully Chipped Away.

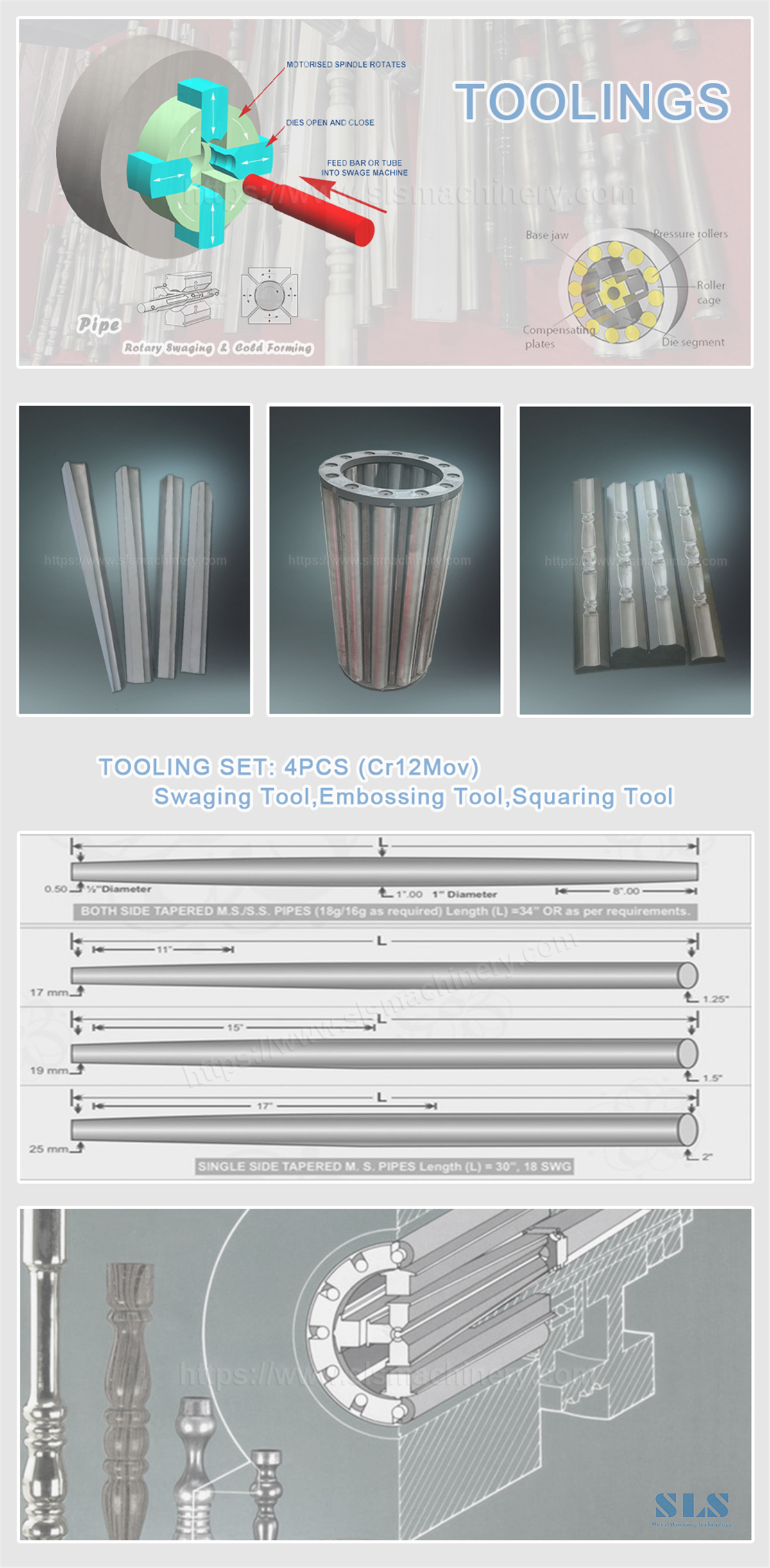

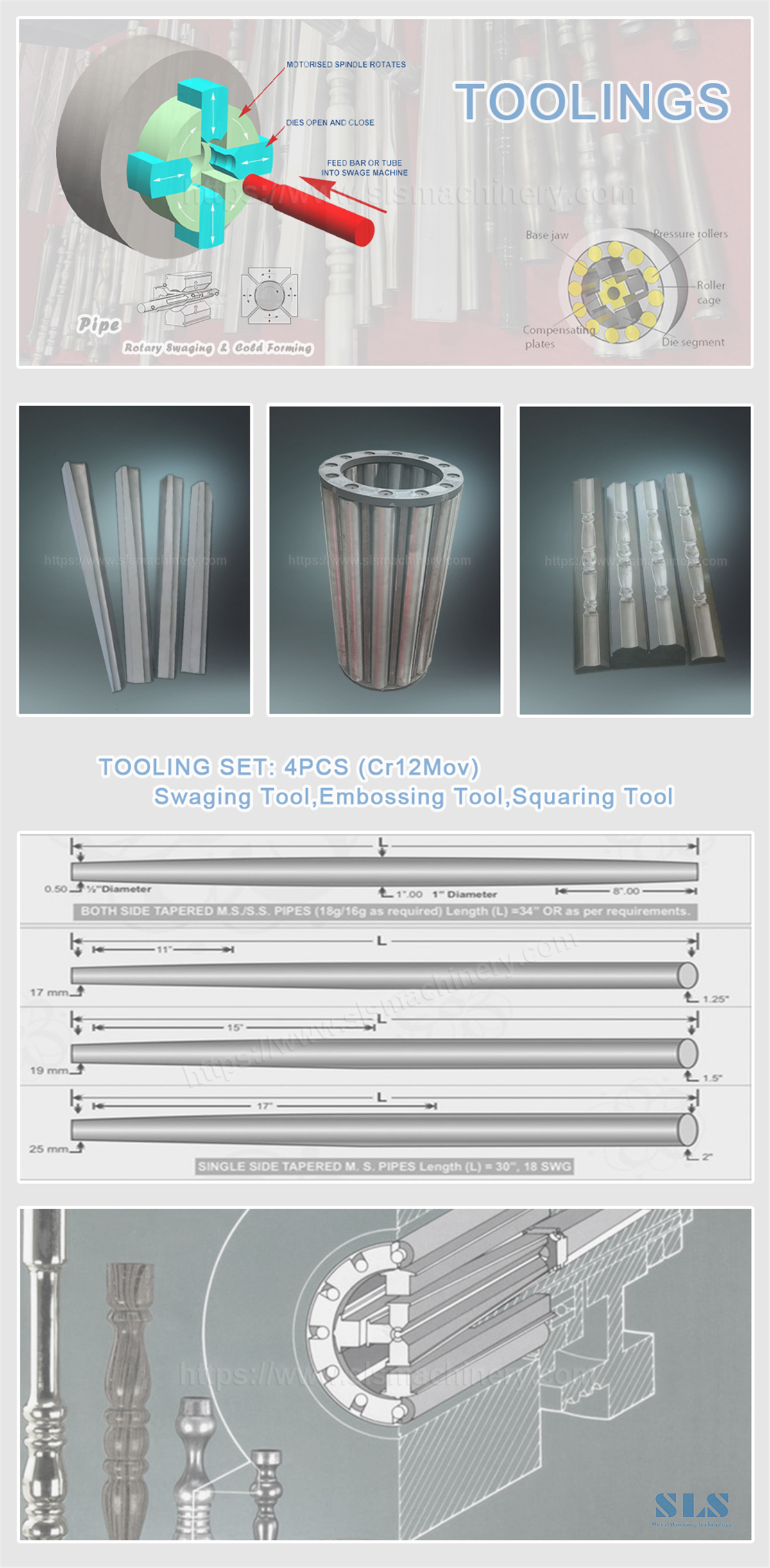

● Low Cost And Flexible Tooling: Rotary Press Tooling Is Incredibly Adaptable, And Die Changes Are Simple And Fast.

● Reduced Labor Costs: Easy To Operate And Does Not Require Highly Skilled Operators, Thus Reducing Labor Costs.

● Using An Auxiliary Mandrel: The Wall Thickness Can Be Better Controlled During The Entire Press Forging Process To Meet Different Processing Needs.

Choosing The Right Pipe Forging Machine Company (SLS Machinery) To Ensure That You Get The Most Efficient Results When Purchasing A Pipe Forging Machine From A Pipe Forging Machine Company, It Is Important To Compare At Least 3 Companies With Our Pipe Forging Machine Performance Parameters.

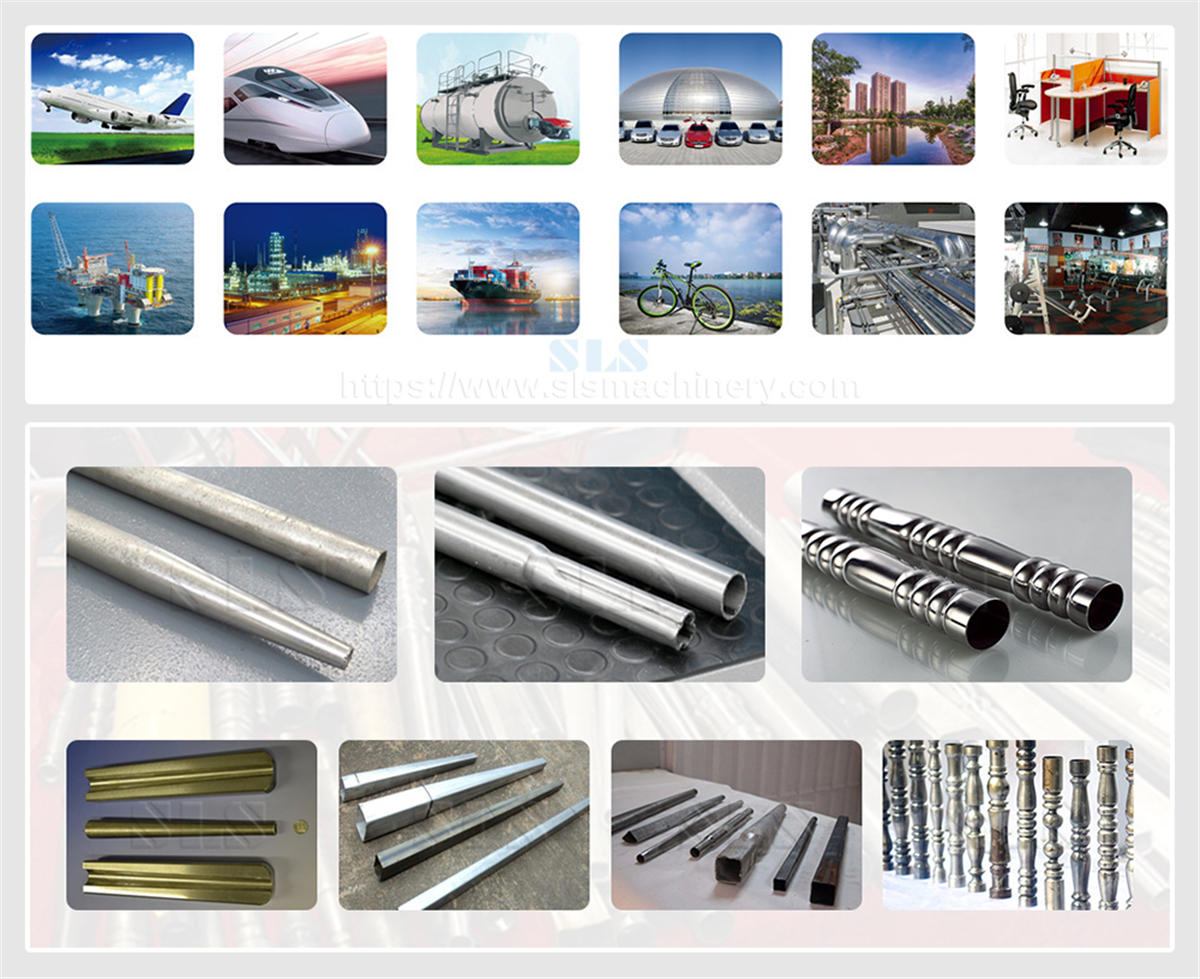

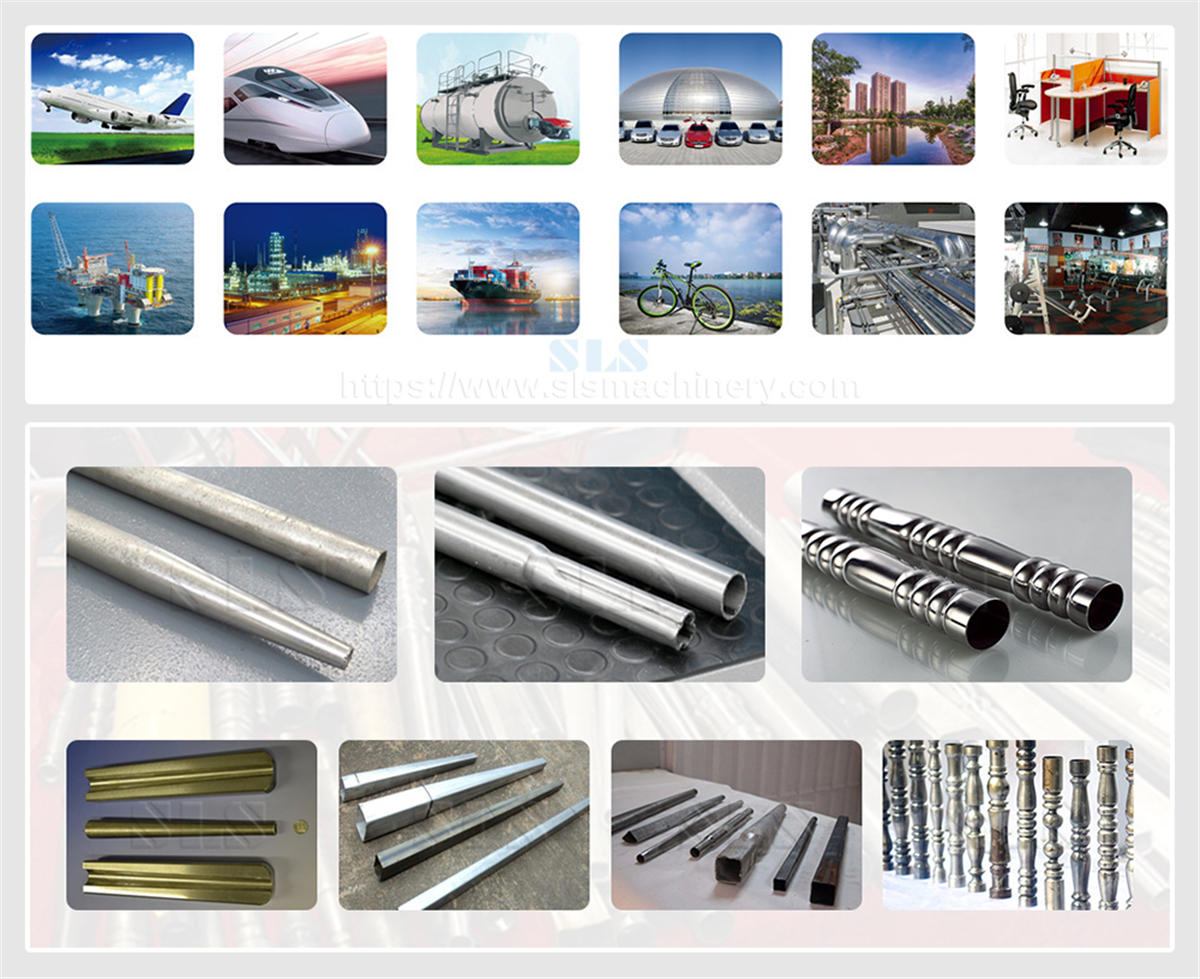

Main Application

Packaging & Shipping

Contact Us

Taper Processing of Mountain Bike Straight Handlebars | Tube Both Ends Forming | Pipe Swaging Production Line

Main Technical Parameters Sheet

Brief Introduction on Tube Both Ends Forming | Pipe Swaging Production Line

Mountain Bike Straight Handlebars, Also Known As Flat Handlebars, Are A Popular Choice For Riders Seeking A More Upright Riding Position And Increased Control On Technical Terrain. The Handlebar Is A Metal Tube With Tapered Ends, With The Following Common Sizes: 31.8mm, 22.2mm, 25.4mm, 23.6mm (Tube Diameter Reduced).

How To Efficiently Produce Bicycle Straight Handlebars, Or What Kind Of Machine Can Be Selected To Produce High-Precision Straight Handlebars?

The SLS Machine's Tube Taper Forming At Both Ends - Automatic Loading And Unloading Production Line Can Efficiently And Conveniently Complete The One-Time Forming Of The Taper At Both Ends Of The Mountain Bike Straight Handlebar With High Precision.

SLS Machinery Is A Professional Manufacturer Of Metal Tube Processing, Ranging From Simple To Complex CNC Machines: Tube Bending Machines, Tube Cutting Machines, Tube End Forming Machines (Cone Tube Machines, Tube Embossing Machines, Tube Square Machines), Chamfering Machines And Other Automated Tube Processing Machines.

Professional Engineers Are Committed To Providing Complete One-Stop Solutions In The Field Of Metal Tube Processing And Customized Market Needs. Please Contact Us For More Information...

Features on Tube Both Ends Forming | Pipe Swaging Production Line

● Taper Processing of Mountain Bike Straight Handlebars.

● High Finish: Because The Finished Product Has A High Finish, Secondary Processing May Not Be Required, Saving Time And Money.

● Quick Assembly: The Taper Can Be Quickly Connected To Various Additional Components, Such As Industrial Pipelines, Auto Parts Axles, Metal Furniture Legs And Other Components.

● Reduced Inventory Requirements: Since Swaging Can Be Done To The Required Size And Surface, There Are Fewer Existing Parts To Maintain.

● Uses Less Material: Material Moves Lengthwise When Hammered Instead Of Being Wastefully Chipped Away.

● Low Cost And Flexible Tooling: Rotary Press Tooling Is Incredibly Adaptable, And Die Changes Are Simple And Fast.

● Reduced Labor Costs: Easy To Operate And Does Not Require Highly Skilled Operators, Thus Reducing Labor Costs.

● Using An Auxiliary Mandrel: The Wall Thickness Can Be Better Controlled During The Entire Press Forging Process To Meet Different Processing Needs.

Choosing The Right Pipe Forging Machine Company (SLS Machinery) To Ensure That You Get The Most Efficient Results When Purchasing A Pipe Forging Machine From A Pipe Forging Machine Company, It Is Important To Compare At Least 3 Companies With Our Pipe Forging Machine Performance Parameters.

Main Application

Packaging & Shipping

Contact Us