+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Our “MC-400CNC-MH Type Multi-Head Round Square Pipe Auto Tube Cutting Machine with Magazine Loader” which is a new model of very high efficiency cut off machine, we can also name it as circular sawing machine. It combined by auto loading part, tube transition part, cutting part and auto unloading part. Machine covers a wide range of pipe size which is appropriated in many industrial areas like auto parts, furniture,tubes manufacture...This machine maximize the cutting efficiency and minimize the cutting cost. By different sawing requirements, cutting heads number can reduce or increase,after cutting,customized function can be as your one stop solution of pipe processing segment.

_________________________________________________________________________

Model: MC-400CNC-MH

Specification: 76mm x 3mm(Can be customized)

Drive Mode: Hybrid Drive (Electric+Hydraulic)

Technical: Cold Saw Cut Off

Business Type: Professoinal Manufacture Factory

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 45 Days Dated From Deposit Received

Warranty: 24months

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

MC-400CNC-MH Type Multi-Head Round Square Pipe Auto Tube Cutting Machine with Magazine Loader

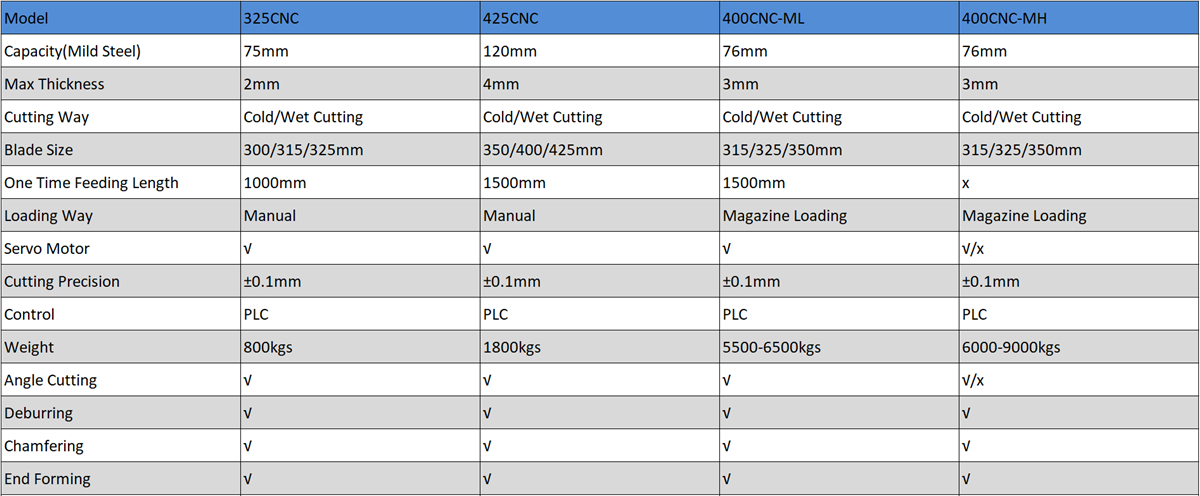

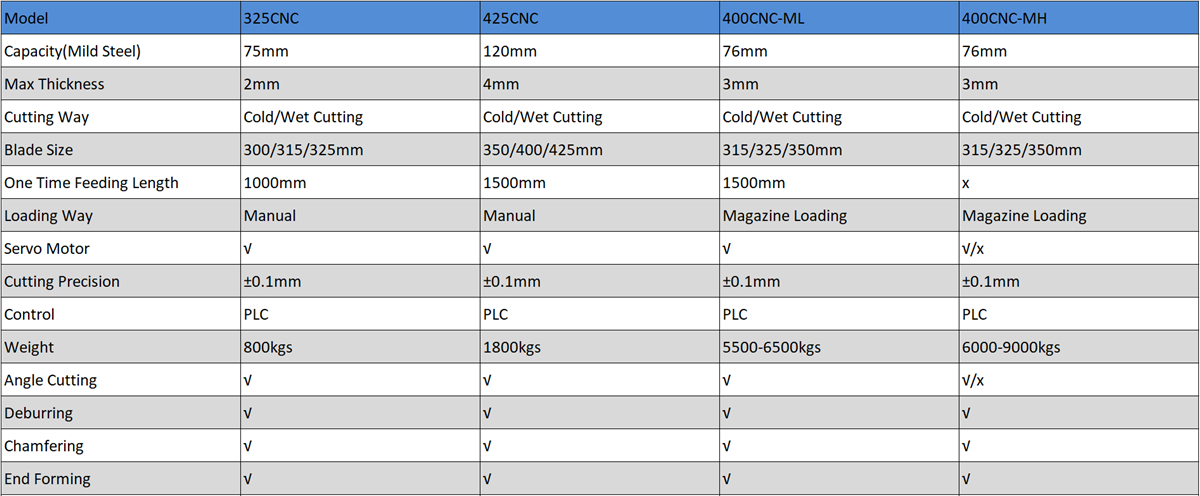

Main Technical Parameters Sheet

Brief Introduction on Multi-Head Magazine Loader Auto Tube Cutting Machine

SLS MC-400CNC-MH Type Multi-Head Round Square Pipe Auto Tube Cutting Machine with Magazine Loader is a real comprehensive and high efficiency equipment specially designed and innovated to big cutting volume needs. From operator point of view, one operator can manage 2 pieces of multi heads cutting line to helps reduce labor cost; From machine work point of view, loading one whole bundle of original pipes into magazine loader, machine will automatically cutting without any helps of worker. Whereas, it not only one piece by one piece cut of,but many pieces cut off together which determined by heads working number,this helps reduce energy consumption and greatly increase output. It is a compatible and versatile machine can serve different pipe size and different pipe shape to maximize working mission. Together with electrical controlling system,this line performs in precision,versatility and stability.

Features on Multi-Head Magazine Loader Auto Tube Cutting Machine

Mechanical Parts:

Heads Distance Adjusting can be flexible choose as by manual or by electric(servo motor).

Several cutting heads working together to greatly increase the working efficiency.

Auto bundle loading reduce labor cost and stable cutting working.

Rigid cast iron cutting head and strong and good quality welded steel structure to reduce machine vibration and increase machine working accuracy.

Clamp tool: front and back clamp way not only convenient auto loading ,but improve the clamp stability.

Available for max 2 cutting pieces together for small pipe size.

Hydraulic Parts&Lubrication:

Hydraulic Controlling: Auto Loading, Tube Clamping(Releasing),Tube Lifting(Down)...

Hydraulic Station: Famous brand valves.

Hydraulic Oil: 46# or 68# anti resist hydraulic oil

Water emulation to lubricate and cooling saw blade.

Lubrication for mechanical movement part to maintain machine working life.

Electrical Parts:

PLC controlling system

Easy control panel to help worker easy operate.

Optional:

Connect with Chamfering Machine

Connect with Deburring Machine

Connect with Pipe Forming Machine

Connect with Pipe Washing System

Servo Motor Cutting Heads Distance Adjust

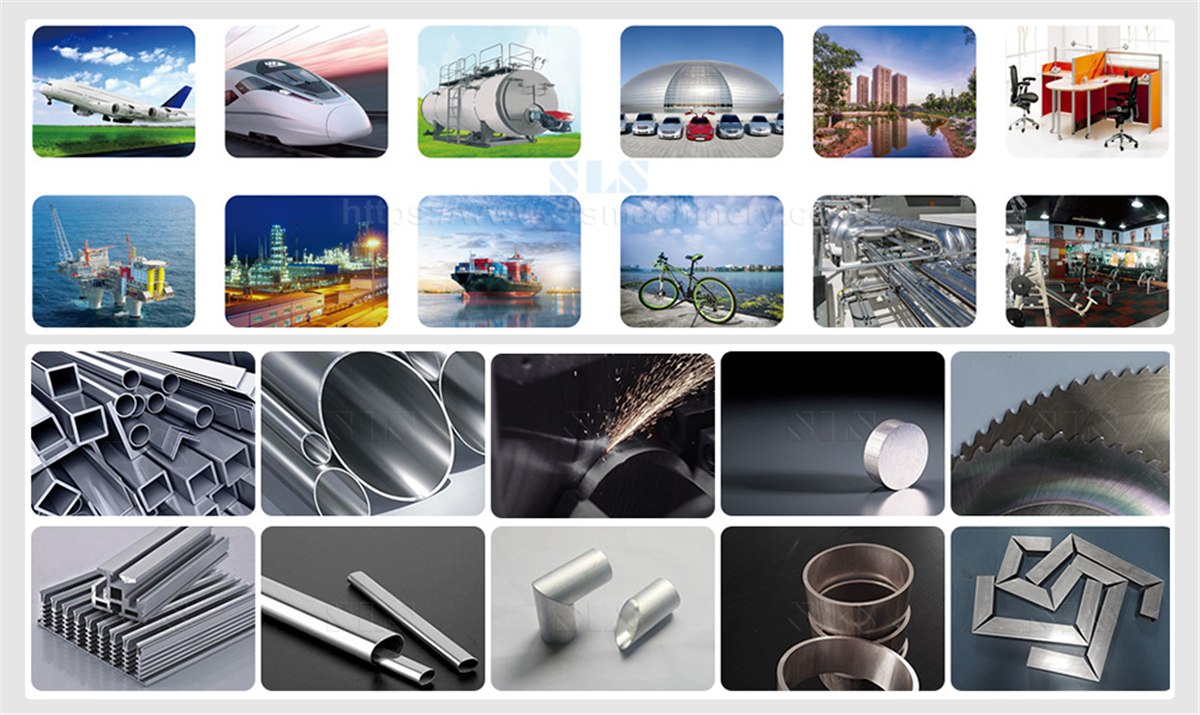

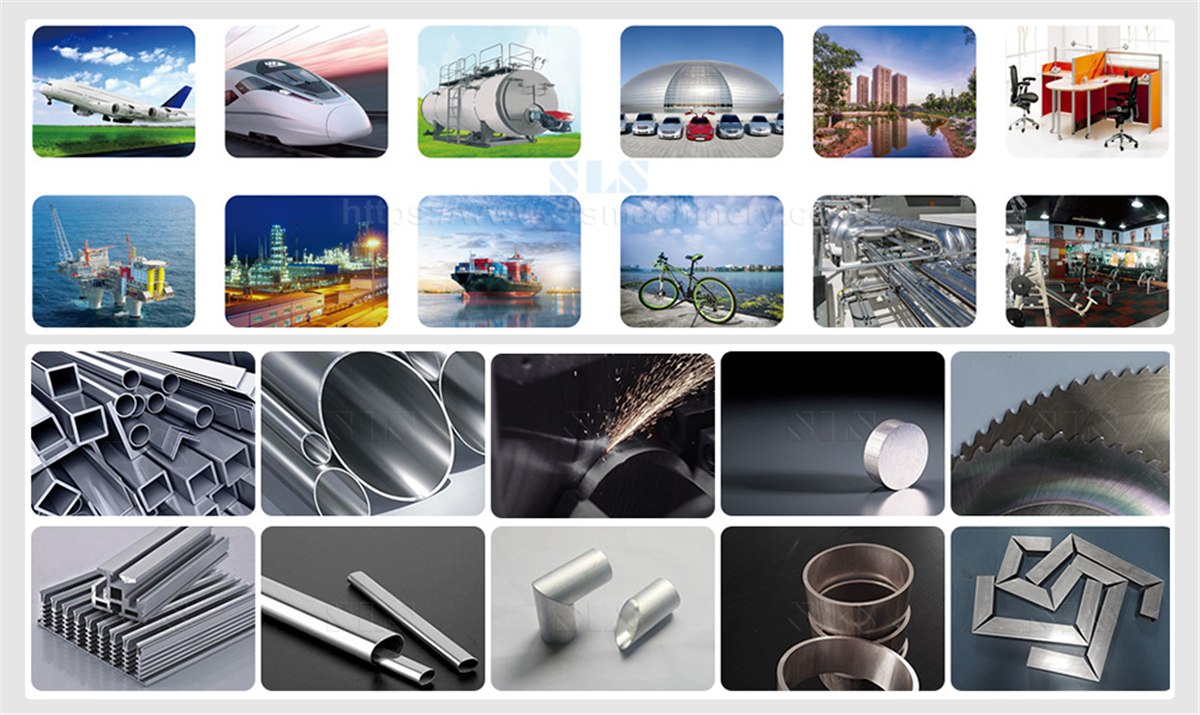

Main Application

Packaging & Shipping

Contact Us

MC-400CNC-MH Type Multi-Head Round Square Pipe Auto Tube Cutting Machine with Magazine Loader

Main Technical Parameters Sheet

Brief Introduction on Multi-Head Magazine Loader Auto Tube Cutting Machine

SLS MC-400CNC-MH Type Multi-Head Round Square Pipe Auto Tube Cutting Machine with Magazine Loader is a real comprehensive and high efficiency equipment specially designed and innovated to big cutting volume needs. From operator point of view, one operator can manage 2 pieces of multi heads cutting line to helps reduce labor cost; From machine work point of view, loading one whole bundle of original pipes into magazine loader, machine will automatically cutting without any helps of worker. Whereas, it not only one piece by one piece cut of,but many pieces cut off together which determined by heads working number,this helps reduce energy consumption and greatly increase output. It is a compatible and versatile machine can serve different pipe size and different pipe shape to maximize working mission. Together with electrical controlling system,this line performs in precision,versatility and stability.

Features on Multi-Head Magazine Loader Auto Tube Cutting Machine

Mechanical Parts:

Heads Distance Adjusting can be flexible choose as by manual or by electric(servo motor).

Several cutting heads working together to greatly increase the working efficiency.

Auto bundle loading reduce labor cost and stable cutting working.

Rigid cast iron cutting head and strong and good quality welded steel structure to reduce machine vibration and increase machine working accuracy.

Clamp tool: front and back clamp way not only convenient auto loading ,but improve the clamp stability.

Available for max 2 cutting pieces together for small pipe size.

Hydraulic Parts&Lubrication:

Hydraulic Controlling: Auto Loading, Tube Clamping(Releasing),Tube Lifting(Down)...

Hydraulic Station: Famous brand valves.

Hydraulic Oil: 46# or 68# anti resist hydraulic oil

Water emulation to lubricate and cooling saw blade.

Lubrication for mechanical movement part to maintain machine working life.

Electrical Parts:

PLC controlling system

Easy control panel to help worker easy operate.

Optional:

Connect with Chamfering Machine

Connect with Deburring Machine

Connect with Pipe Forming Machine

Connect with Pipe Washing System

Servo Motor Cutting Heads Distance Adjust

Main Application

Packaging & Shipping

Contact Us