+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Our MC-325CNC Type Pneumatic Metal Steel Copper Aluminum Small Tube 45 Degree Pipe Saw Cutting Machine Series Can Do Different Cutting Volume Based on Customer's Production Requiremen Covering a Wide Range of Diameters and Applications. Are you searching for an automatic cutting machine for cutting metal pipes based on economy but with certain production efficiency? If you are interested in our cold sawing machine, we will provide you a comprehensive solution for pipe cutting, allowing you to spend less cost,but more smoothly put into production. We always strive to find the most suitable pipe cutting solution, taking not only your ideas but also your needs into consideration during the process.In consultation with you, we will consider which type of cutting machine best suits your production and budget requirements. So, contact us now.

_________________________________________________________________________

Model: MC-325CNC (Pneumatic or Hydraulic)

Specification: 75mm x 2mm

Drive Mode: Electric+Hydraulic

Technical: Tube Cold Cutting Sawing

Business Type: Professoinal Manufacture

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 20-25 Days Dated From Deposit Received

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

MC-325CNC Type Pneumatic Metal Steel Copper Aluminum Small Tube 45 Degree Pipe Saw Cutting Machine

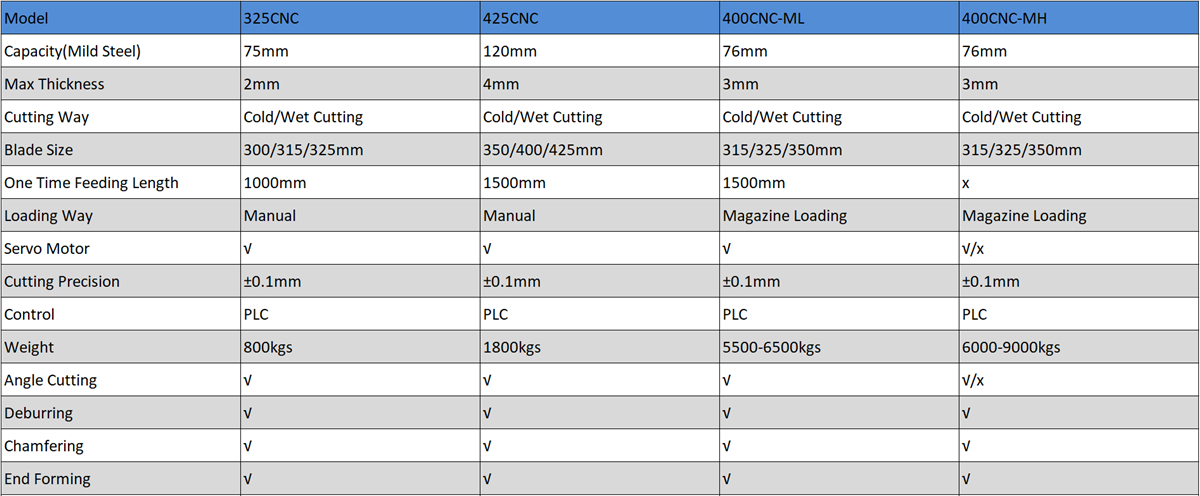

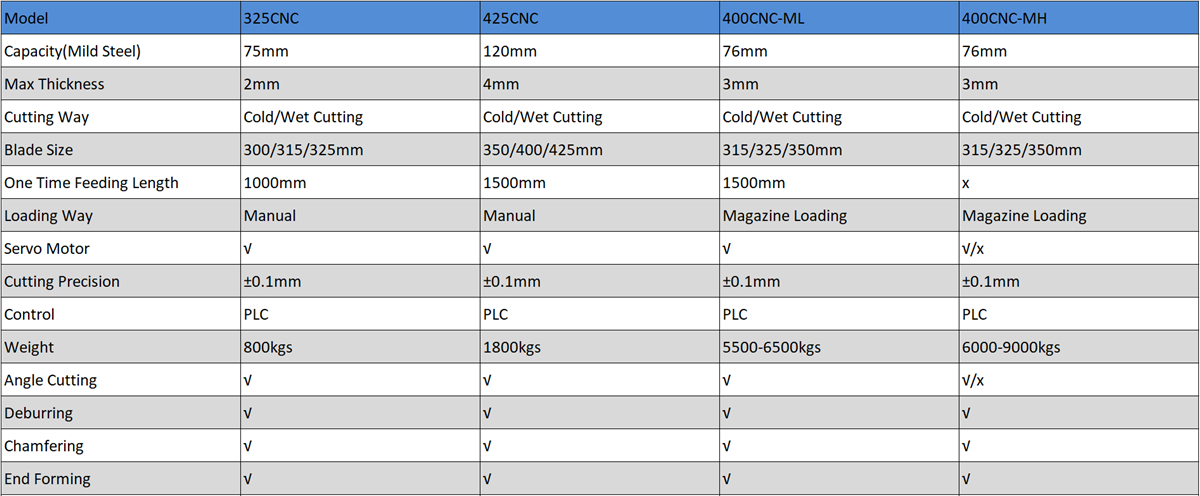

Main Technical Parameters Sheet

Brief Introduction on Small Tube 45 Degree Pipe Saw Cutting Machine

SLS MC-325CNC Type Pneumatic Metal Steel Copper Aluminum Small Tube 45 Degree Pipe Saw Cutting Machine-An excellent choice for cutting of small to medium production. Automatic cold saws combine classic circular saw cutting principles with CNC/NC-controlled feed and grip clamp, also offering extreme economy and flexibility. The design also takes into account the ergonomic operator panel including emergency stop, programming console(touch screen) and cutting parameters. Why cold saws been so popular among all industrial sawing and cuttings? Because it is simple to use, versatile and powerful. The sawing head is unified and standard, thus customers can also upgrade to a production line for cutting metal pipes by adding auto loading and unloading systems. Of course, different industries have completely different cutting solutions.After all, the process involves not only just sawing, we can also take care of deburring, chamfering, measuring, end forming and cleaning where tube after cutting.

Features on Small Tube 45 Degree Pipe Saw Cutting Machine

Interactive PLC and Touch Screen Controlling Offers Easy Access to Auto and Manual Operating Modes.

Worm and gear drive for trouble-free operation

Adjustable Cutting Length Which Can Be Set on Touch Screen.

Hydraulic or pneumatic driven system

2-speed motor for flexible cutting

Rigid Cast Iron Saw Bases and Electro-Welded Steel Frames Maintain Accuracy And Minimize Vibrations, Even At Full Capacity.

Cutting Shape Available: Round, Square, Rectangle and Other Profiles.

Available for Several Pieces Cutting Together for Small Pipe Size.

2 Sides and 2 Way Clamping System: High Precision Cutting, Reduce Vibration and Soundless While Cutting.

Clamping, Saw Blade Advancing and Backward, Clamp Releasing Are Hydraulic or Pneumatic Driven.

Automatic cutting cycle

Automatic feeding cycle

Automatic clamp vise clamp and release

Heavy-duty sheet metal base

Good Cutting Quality for Tube Internal and External Without Burs.

Small Noisy

Water Cooling and Lubricate System Prolongs The Life of Machine and Saw Blade.

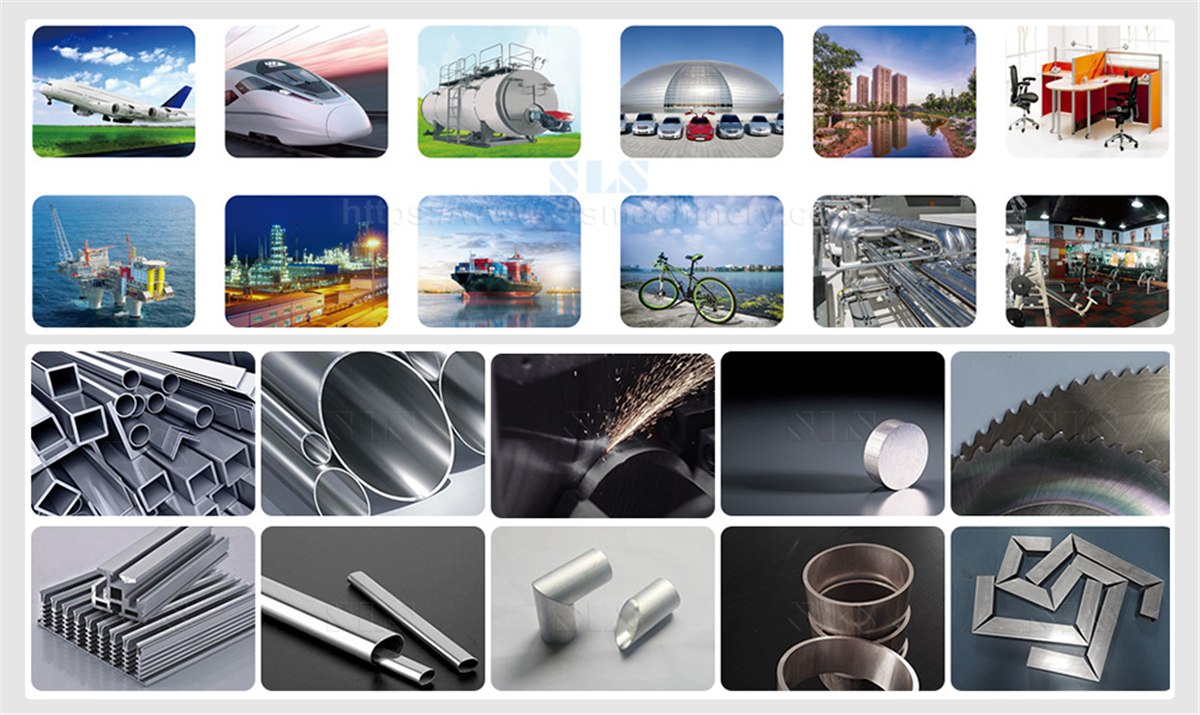

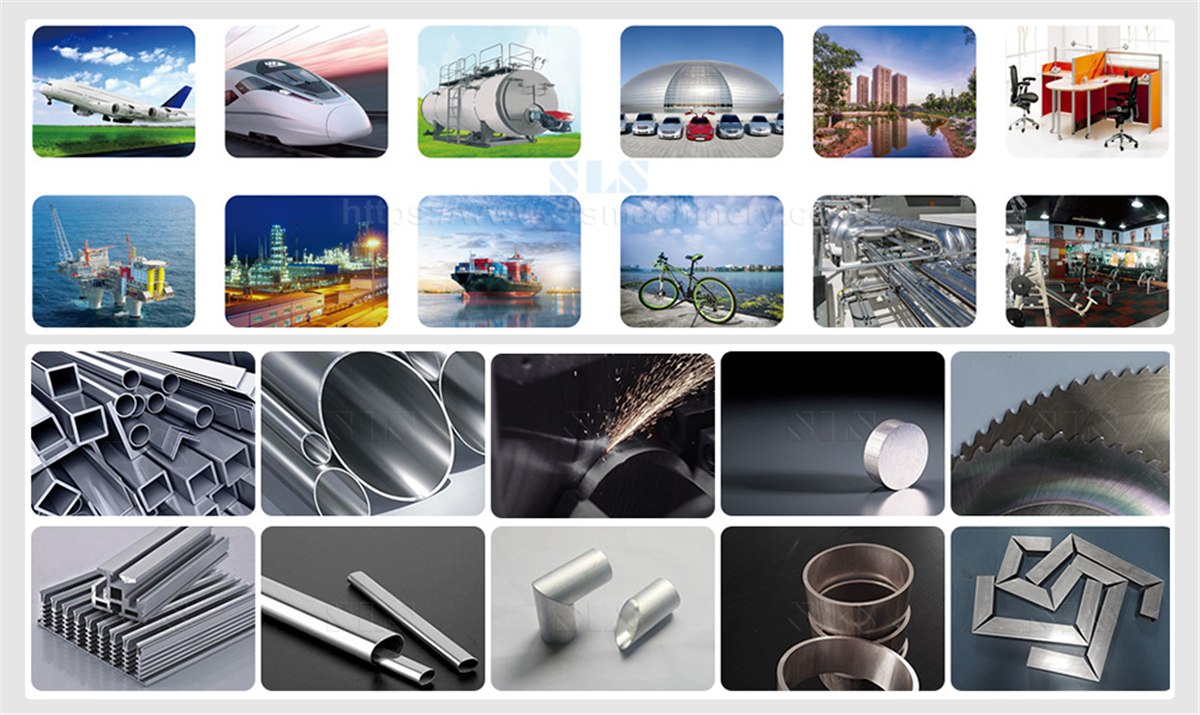

Main Application

Packaging & Shipping

Contact Us

MC-325CNC Type Pneumatic Metal Steel Copper Aluminum Small Tube 45 Degree Pipe Saw Cutting Machine

Main Technical Parameters Sheet

Brief Introduction on Small Tube 45 Degree Pipe Saw Cutting Machine

SLS MC-325CNC Type Pneumatic Metal Steel Copper Aluminum Small Tube 45 Degree Pipe Saw Cutting Machine-An excellent choice for cutting of small to medium production. Automatic cold saws combine classic circular saw cutting principles with CNC/NC-controlled feed and grip clamp, also offering extreme economy and flexibility. The design also takes into account the ergonomic operator panel including emergency stop, programming console(touch screen) and cutting parameters. Why cold saws been so popular among all industrial sawing and cuttings? Because it is simple to use, versatile and powerful. The sawing head is unified and standard, thus customers can also upgrade to a production line for cutting metal pipes by adding auto loading and unloading systems. Of course, different industries have completely different cutting solutions.After all, the process involves not only just sawing, we can also take care of deburring, chamfering, measuring, end forming and cleaning where tube after cutting.

Features on Small Tube 45 Degree Pipe Saw Cutting Machine

Interactive PLC and Touch Screen Controlling Offers Easy Access to Auto and Manual Operating Modes.

Worm and gear drive for trouble-free operation

Adjustable Cutting Length Which Can Be Set on Touch Screen.

Hydraulic or pneumatic driven system

2-speed motor for flexible cutting

Rigid Cast Iron Saw Bases and Electro-Welded Steel Frames Maintain Accuracy And Minimize Vibrations, Even At Full Capacity.

Cutting Shape Available: Round, Square, Rectangle and Other Profiles.

Available for Several Pieces Cutting Together for Small Pipe Size.

2 Sides and 2 Way Clamping System: High Precision Cutting, Reduce Vibration and Soundless While Cutting.

Clamping, Saw Blade Advancing and Backward, Clamp Releasing Are Hydraulic or Pneumatic Driven.

Automatic cutting cycle

Automatic feeding cycle

Automatic clamp vise clamp and release

Heavy-duty sheet metal base

Good Cutting Quality for Tube Internal and External Without Burs.

Small Noisy

Water Cooling and Lubricate System Prolongs The Life of Machine and Saw Blade.

Main Application

Packaging & Shipping

Contact Us