+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Our 89 NC Type Stainless Steel Aluminum Door Frame And Window Guide Rail Profile Bending Machine | Special Shaped Pipes Curved Bender Is A Device That Uses Mechanical Force Or Hydraulic Drive And A Mold To Plastically Bend Metal Pipes And Profiles. The Core Principle Is To Clamp The Material Through A Fixed End, Use A Bending Die Or Roller To Apply Radial Pressure, And Bend The Material Around A Predetermined Axis, While Using Anti-Wrinkle Blocks Or Mandrels To Prevent Cross-Sectional Deformation. In The Processing Of Door Frames, Window Frames, Guide Rails, Profiles And Special Pipes (Such As Special-Shaped Pipes And Thin-Walled Pipes), Pipe Bender Has Become A Key Equipment Due To Its High Precision And High Efficiency. For Example, Aluminum Alloy Or Stainless Steel Door Frames And Window Frames Often Need To Be Bent At Multiple Angles To Meet The Needs Of Building Structures, Such As Curved Floor-To-Ceiling Windows Or Arched Door Designs. The Pipe Bender Can Accurately Achieve Complex Shapes Such As Arcs And Right Angles To Ensure Seamless Splicing.

_________________________________________________________________________

Model: 89NC

Specification: Special Shaped (All)

Drive Mode: Electric + Hydraulic

Suit Bending: 2D Bending

Business Type: Professoinal Manufacturer

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 35 Days Dated From Deposit Received

Contact us :info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

89 NC Type Stainless Steel Aluminum Door Frame and Window Guide Rail Profile Bending Machine | Special Shaped Pipes Curved Bender

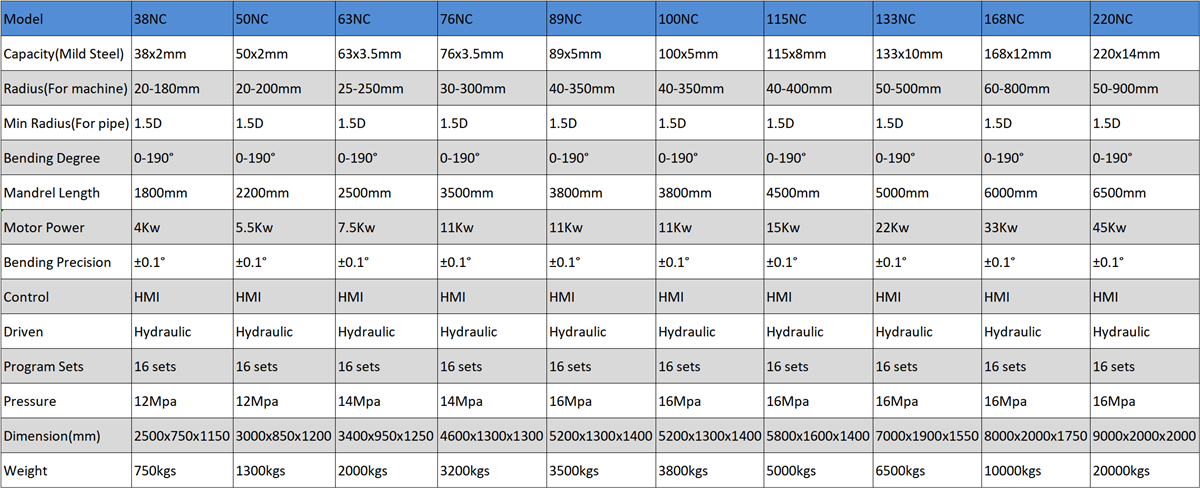

Main Technical Parameters Sheet

Brief Introduction on Door Frame and Window Guide Rail Profile Bending Machine

A Pipe Bender Is A Device That Uses Mechanical Force Or Hydraulic Drive And Dies To Plastically Bend Metal Pipes And Profiles. Its Core Principle Is To Clamp The Material At The Fixed End, Apply Radial Pressure Using A Bending Die Or Roller, And Bend The Material Around A Predetermined Axis, While Using Anti-Wrinkle Blocks Or Mandrels To Prevent Cross-Sectional Deformation. In The Processing Of Door Frames, Window Frames, Guide Rails, Profiles And Special Pipes (Such As Special-Shaped Pipes And Thin-Walled Pipes), Pipe Benders Have Become Key Equipment Due To Their High Precision And High Efficiency.

Application Scenarios

1. Door And Window Frames: Aluminum Alloy Or Stainless Steel Door And Window Frames Often Need To Be Bent At Multiple Angles To Meet The Needs Of Building Structures, Such As Curved Floor-To-Ceiling Windows Or Arched Door Designs. The Pipe Bending Machine Can Accurately Achieve Complex Shapes Such As Arcs And Right Angles To Ensure Seamless Splicing.

2. Guide Rails And Profiles: Automation Equipment Guide Rails, Shelf Support Profiles, Etc. Require High Straightness And Arc Consistency. The Pipe Bending Machine Controls The Bending Angle And Radius Through The CNC System, Which Is Suitable For Mass Production.

3. Special Pipes: For Special-Shaped Cross-Section Materials Such As Flat Pipes For Furniture And Automobile Exhaust Pipes, Customized Molds Are Required. The Pipe Bending Machine Achieves Diversified Bending By Replacing The Mold To Avoid Indentations Or Cracks Caused By Traditional Processing.

The Key Role Of Pipe Bending Machines In The Fields Of Construction, Home Furnishing And Industry Stems From Their Ability To Combine The Theory Of Material Plastic Deformation With Modern CNC Technology. They Can Not Only Meet The Aesthetics Of Complex Designs, But Also Take Into Account Functionality And Production Efficiency, Making Them Irreplaceable Equipment In Profile Processing.

Features on Door Frame and Window Guide Rail Profile Bending Machine

● Human Interface/PLC Controlling System Offers Easy Access to Auto and Manual Operating Modes.

● Maximum 16 Sets Of Program Storage, Maximum 16 Bends for Each Program.

● Standard Clockwise Bending Direction.

● Mounted as Adjustable Speed Valve on Pressure Die Ensures The Synchronization of Bending.

● Encoder Installation Ensures The Accuracy and Stability of Bending.

● Machine Equipped with Mandrel Or Non Mandrel Bending.

● Bending Axis-Driven By Hydraulic, Feeding Axis-Manual, Rotating Axis-Manual.

● Available Bending Material In Steel, Stainless, Aluminum, Brass, Alloy ...

● Available Pipe Shape: Round, Square, Rectangle, Oval, Bar, Profile...

● Electric: As Required (3 Phase 220V Or 380V Or 415V...)

● Water Cooling System.

Main Application

Packaging & Shipping

Contact Us

89 NC Type Stainless Steel Aluminum Door Frame and Window Guide Rail Profile Bending Machine | Special Shaped Pipes Curved Bender

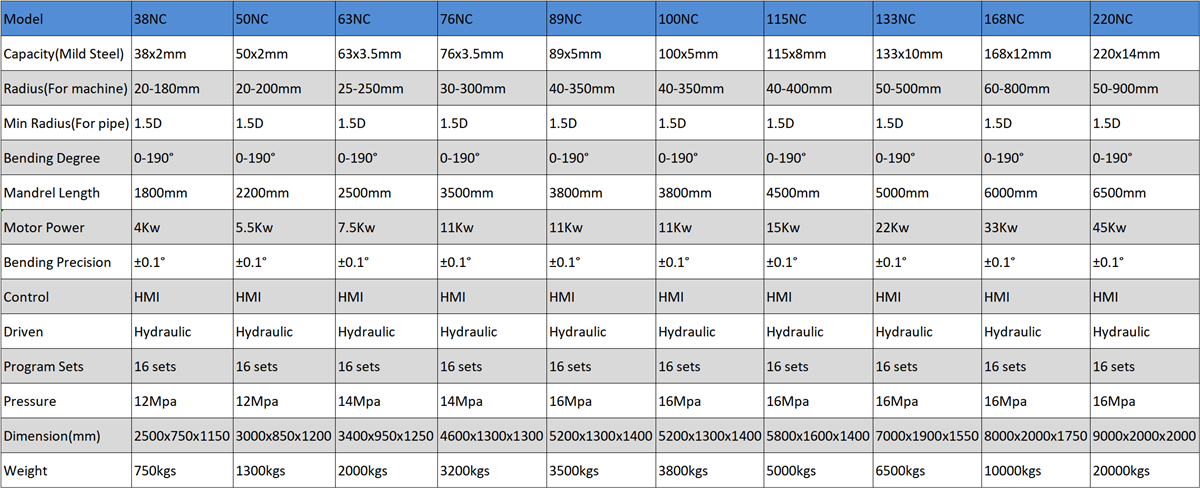

Main Technical Parameters Sheet

Brief Introduction on Door Frame and Window Guide Rail Profile Bending Machine

A Pipe Bender Is A Device That Uses Mechanical Force Or Hydraulic Drive And Dies To Plastically Bend Metal Pipes And Profiles. Its Core Principle Is To Clamp The Material At The Fixed End, Apply Radial Pressure Using A Bending Die Or Roller, And Bend The Material Around A Predetermined Axis, While Using Anti-Wrinkle Blocks Or Mandrels To Prevent Cross-Sectional Deformation. In The Processing Of Door Frames, Window Frames, Guide Rails, Profiles And Special Pipes (Such As Special-Shaped Pipes And Thin-Walled Pipes), Pipe Benders Have Become Key Equipment Due To Their High Precision And High Efficiency.

Application Scenarios

1. Door And Window Frames: Aluminum Alloy Or Stainless Steel Door And Window Frames Often Need To Be Bent At Multiple Angles To Meet The Needs Of Building Structures, Such As Curved Floor-To-Ceiling Windows Or Arched Door Designs. The Pipe Bending Machine Can Accurately Achieve Complex Shapes Such As Arcs And Right Angles To Ensure Seamless Splicing.

2. Guide Rails And Profiles: Automation Equipment Guide Rails, Shelf Support Profiles, Etc. Require High Straightness And Arc Consistency. The Pipe Bending Machine Controls The Bending Angle And Radius Through The CNC System, Which Is Suitable For Mass Production.

3. Special Pipes: For Special-Shaped Cross-Section Materials Such As Flat Pipes For Furniture And Automobile Exhaust Pipes, Customized Molds Are Required. The Pipe Bending Machine Achieves Diversified Bending By Replacing The Mold To Avoid Indentations Or Cracks Caused By Traditional Processing.

The Key Role Of Pipe Bending Machines In The Fields Of Construction, Home Furnishing And Industry Stems From Their Ability To Combine The Theory Of Material Plastic Deformation With Modern CNC Technology. They Can Not Only Meet The Aesthetics Of Complex Designs, But Also Take Into Account Functionality And Production Efficiency, Making Them Irreplaceable Equipment In Profile Processing.

Features on Door Frame and Window Guide Rail Profile Bending Machine

● Human Interface/PLC Controlling System Offers Easy Access to Auto and Manual Operating Modes.

● Maximum 16 Sets Of Program Storage, Maximum 16 Bends for Each Program.

● Standard Clockwise Bending Direction.

● Mounted as Adjustable Speed Valve on Pressure Die Ensures The Synchronization of Bending.

● Encoder Installation Ensures The Accuracy and Stability of Bending.

● Machine Equipped with Mandrel Or Non Mandrel Bending.

● Bending Axis-Driven By Hydraulic, Feeding Axis-Manual, Rotating Axis-Manual.

● Available Bending Material In Steel, Stainless, Aluminum, Brass, Alloy ...

● Available Pipe Shape: Round, Square, Rectangle, Oval, Bar, Profile...

● Electric: As Required (3 Phase 220V Or 380V Or 415V...)

● Water Cooling System.

Main Application

Packaging & Shipping

Contact Us