+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

115NC Type Pipe Tubing Bender Tools and Dies / Making Machine Bend Pipes for Sale, NC Pipe and Tube Bending Machines Are Our Models Which Will Help You to Reach Your Target with The Most Economical and Practical Way on Pipe and Tube Bending Works for Small to Medium Productions Environments. The Machine Adopting Solenoid Valve and Integrated Circuit to Control Separately, Which Can Be Extend The Life of The Hydraulic Parts. Our Bender Machines, Which Have Been In The Sector for Many Years, Will Be Your Durable, Long-Lasting and Reliable Equipment for Your Production.

_________________________________________________________________________

Model: 115NC

Specification: 115mm(4.5")x8mm

Drive Mode: Electric + Hydraulic

Suit Bending: 2D Bend

Business Type: Professoinal Manufacturer

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 35 Days Dated From Deposit Received

Contact us :info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

115NC Type Pipe Tubing Bender Tools and Dies / Making Machine Bend Pipes for Sale

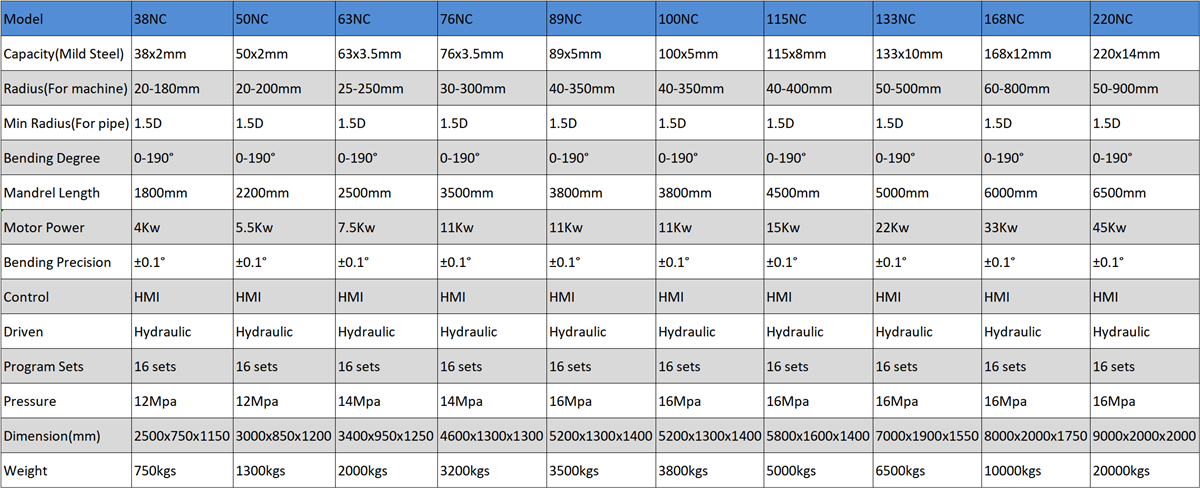

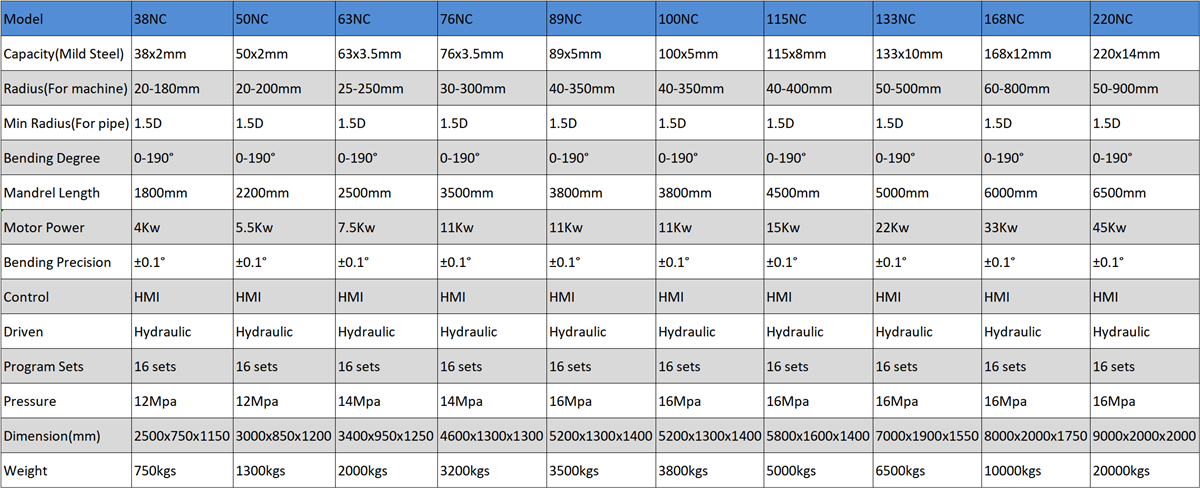

Main Technical Parameters Sheet

Brief Introduction on Pipe Tubing Bender Tools and Dies / Making Machine Bend Pipes

SLS 115NC Type Pipe Tubing Bender Tools and Dies / Making Machine Bend Pipes for Sale, Semi-Automatic Tube Bending Machine Has an NC Control Unit to Allow The Operator to Program The Bend Degree (C Axis)-The Standard Memory Can Store Up to 16 Programs Each With 16 Sequential Bends. This Allows The Operator to Select From The Memory to Bend Sequence They Require and Load The Tube and Start Bending. The Rotating and Feeding (B&Y Axis) Are Controlled Manually, That Means Semi-Automatic Tube Bender Will NOT Reposition The Tube Between Bends. Other Movements As Die Working, Mandrel Working Are Controlled By Hydraulic. NC Pipe Bending Machine Combines Easy-to-Use Operation with High Bending Accuracy and Cost Effectiveness. It Is The Practical Semi-Automatic Solution for Small to Medium Productions. If You Want to Automatically Produce a Tube with Numerous Bends with Limited Operator Involvement Between Each Bend, You May Need a CNC Tube Bender.

Features on Pipe Tubing Bender Tools and Dies / Making Machine Bend Pipes

● Human Interface/PLC Controlling System Offers Easy Access to Auto and Manual Operating Modes.

● Standard Clockwise Bending Direction.

● Maximum 16 Sets Of Program Storage, Maximum 16 Bends for Each Program.

● Encoder Installation Ensures The Accuracy and Stability of Bending.

● Mounted as Adjustable Speed Valve on Pressure Die Ensures The Synchronization of Bending.

● Machine Equipped with Mandrel Or Non Mandrel Bending.

● Bending Axis-Driven By Hydraulic, Feeding Axis-Manual, Rotating Axis-Manual.

● Available Bending Material In Steel, Stainless, Aluminum, Brass, Alloy ...

● Available Pipe Shape: Round, Square, Rectangle, Oval, Bar, Profile...

● Water Cooling System.

● Electric: As Required (3 Phase 220V Or 380V Or 415V...)

Main Application

Packaging & Shipping

Contact Us

115NC Type Pipe Tubing Bender Tools and Dies / Making Machine Bend Pipes for Sale

Main Technical Parameters Sheet

Brief Introduction on Pipe Tubing Bender Tools and Dies / Making Machine Bend Pipes

SLS 115NC Type Pipe Tubing Bender Tools and Dies / Making Machine Bend Pipes for Sale, Semi-Automatic Tube Bending Machine Has an NC Control Unit to Allow The Operator to Program The Bend Degree (C Axis)-The Standard Memory Can Store Up to 16 Programs Each With 16 Sequential Bends. This Allows The Operator to Select From The Memory to Bend Sequence They Require and Load The Tube and Start Bending. The Rotating and Feeding (B&Y Axis) Are Controlled Manually, That Means Semi-Automatic Tube Bender Will NOT Reposition The Tube Between Bends. Other Movements As Die Working, Mandrel Working Are Controlled By Hydraulic. NC Pipe Bending Machine Combines Easy-to-Use Operation with High Bending Accuracy and Cost Effectiveness. It Is The Practical Semi-Automatic Solution for Small to Medium Productions. If You Want to Automatically Produce a Tube with Numerous Bends with Limited Operator Involvement Between Each Bend, You May Need a CNC Tube Bender.

Features on Pipe Tubing Bender Tools and Dies / Making Machine Bend Pipes

● Human Interface/PLC Controlling System Offers Easy Access to Auto and Manual Operating Modes.

● Standard Clockwise Bending Direction.

● Maximum 16 Sets Of Program Storage, Maximum 16 Bends for Each Program.

● Encoder Installation Ensures The Accuracy and Stability of Bending.

● Mounted as Adjustable Speed Valve on Pressure Die Ensures The Synchronization of Bending.

● Machine Equipped with Mandrel Or Non Mandrel Bending.

● Bending Axis-Driven By Hydraulic, Feeding Axis-Manual, Rotating Axis-Manual.

● Available Bending Material In Steel, Stainless, Aluminum, Brass, Alloy ...

● Available Pipe Shape: Round, Square, Rectangle, Oval, Bar, Profile...

● Water Cooling System.

● Electric: As Required (3 Phase 220V Or 380V Or 415V...)

Main Application

Packaging & Shipping

Contact Us