+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Our 89 Type 2A-1S Large Radius 3/3.5" Inch Cnc Tube Bender Hydraulic Auxiliary Driving Mandrel Pipe Bending Machine Create Value for Our Customers In Applications of Automotive Parts, Marine/Shipbuilding, Furniture Industry, Boiler Industry, Out-door Products, Vehicle Industry, And Many More By Providing Solutions which Maximize The Quality and Production Efficiency.

_________________________________________________________________________

Model: 89CNC

Specification: 89mm(3.5")x5mm

Drive Mode: Electric + Hydraulic

Suit Bending: 3D Bend (Multi Radius)

Business Type: Professoinal Manufacturer

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 35 Days Dated From Deposit Received

Contact us :info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

89 Type 2A-1S Large Radius 3/3.5" Inch Cnc Tube Bender Hydraulic Auxiliary Driving Mandrel Pipe Bending Machine

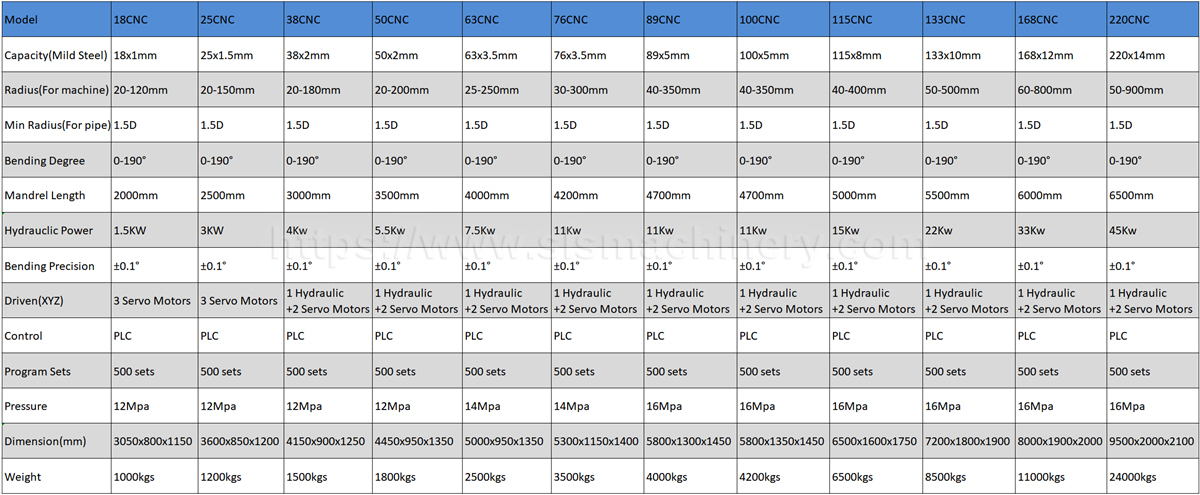

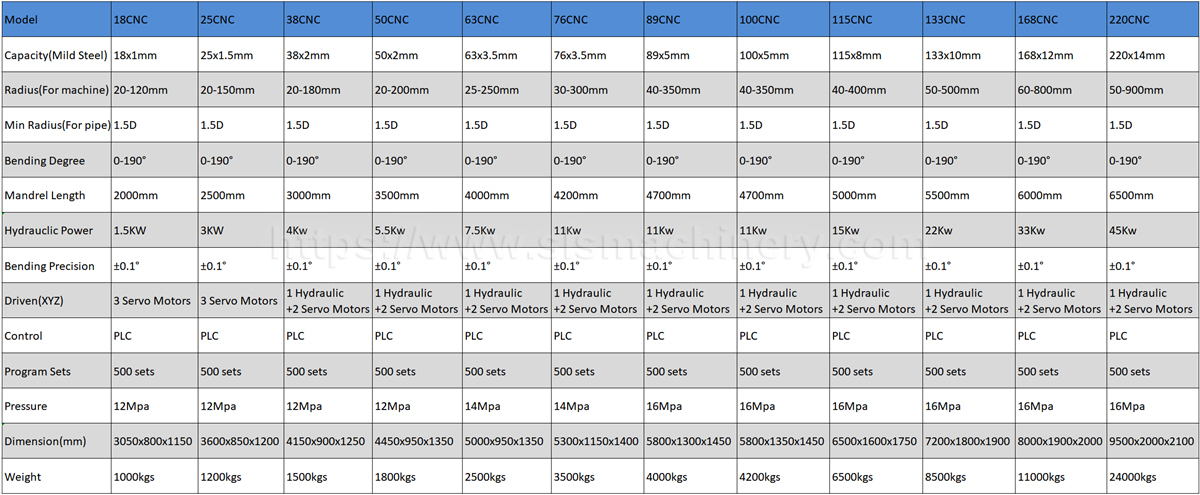

Main Technical Parameters Sheet

Brief Introduction on Large Radius Mandrel Pipe Bending Machine

SLS 89 Type 2A-1S Large Radius 3/3.5" Inch Cnc Tube Bender Hydraulic Auxiliary Driving Mandrel Pipe Bending Machine Equipped with PLC Which Manage Bending (Y), Feeding (X) & Rotation (Z) In a Complete Automatic Cycle.

Bending (Y-Axis): Controlled by Hydraulic.

Feeding (X-Axis): Controlled by Servomotor.

Rotating (Z-Axis): Controlled by Servomotor.

This Value Priced Large Radius CNC Mandrel Pipe Bending Machine Is an Excellent Choice for General Purpose and Any Type of Conventional Tube Bending Applications.CNC Tube Benders Can Make Complex Bends To a Very High Degree of Precision That NC Model or Hand Operate Simply Can’t Match. Today, Most Bending Only Needs Human Assistance, Not Constant Guidance. This Is Possible Because of CNC Bending Machines.

Features on Large Radius Mandrel Pipe Bending Machine

● Interactive PLC Touch Screen Offers Easy Access to Auto And Manual Operating Modes.

● System Diagnostics and Multiple Language Capability.

● Standard Clockwise Bending Direction.

● Maximum 500 Sets of Program Storage,Maximum 32 Bends for Each Program.

● With Independent Programmable Speeds on Y, B(By Electrical Adjust) and C Axis(By Oil Flow Adjust).

● Bending Axis-Driven by Cylinder,Feeding Axis-Driven by Servo Motor,Rotating Axis-Driven by Servo Motor.

● Obtain Quality Repeatable Bends In Steel, Stainless, Aluminum, Titanium and Brass.

● With Air Cooling System or Water Cooling System.

● One Set of Tooling for Draw Bending.

● Electric: As Required (3 Phase 220V or 380V or 415V...).

Main Application

Packaging & Shipping

Contact Us

89 Type 2A-1S Large Radius 3/3.5" Inch Cnc Tube Bender Hydraulic Auxiliary Driving Mandrel Pipe Bending Machine

Main Technical Parameters Sheet

Brief Introduction on Large Radius Mandrel Pipe Bending Machine

SLS 89 Type 2A-1S Large Radius 3/3.5" Inch Cnc Tube Bender Hydraulic Auxiliary Driving Mandrel Pipe Bending Machine Equipped with PLC Which Manage Bending (Y), Feeding (X) & Rotation (Z) In a Complete Automatic Cycle.

Bending (Y-Axis): Controlled by Hydraulic.

Feeding (X-Axis): Controlled by Servomotor.

Rotating (Z-Axis): Controlled by Servomotor.

This Value Priced Large Radius CNC Mandrel Pipe Bending Machine Is an Excellent Choice for General Purpose and Any Type of Conventional Tube Bending Applications.CNC Tube Benders Can Make Complex Bends To a Very High Degree of Precision That NC Model or Hand Operate Simply Can’t Match. Today, Most Bending Only Needs Human Assistance, Not Constant Guidance. This Is Possible Because of CNC Bending Machines.

Features on Large Radius Mandrel Pipe Bending Machine

● Interactive PLC Touch Screen Offers Easy Access to Auto And Manual Operating Modes.

● System Diagnostics and Multiple Language Capability.

● Standard Clockwise Bending Direction.

● Maximum 500 Sets of Program Storage,Maximum 32 Bends for Each Program.

● With Independent Programmable Speeds on Y, B(By Electrical Adjust) and C Axis(By Oil Flow Adjust).

● Bending Axis-Driven by Cylinder,Feeding Axis-Driven by Servo Motor,Rotating Axis-Driven by Servo Motor.

● Obtain Quality Repeatable Bends In Steel, Stainless, Aluminum, Titanium and Brass.

● With Air Cooling System or Water Cooling System.

● One Set of Tooling for Draw Bending.

● Electric: As Required (3 Phase 220V or 380V or 415V...).

Main Application

Packaging & Shipping

Contact Us