+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Our TM-60NC Type 2 Station Press Pipe Edge Shrinkage Docking Tube End Forming Machine Can Do End Forming The Parts According to Customer's Drawings, Covering a Wide Range Of Diameters and Applications. It Is Mainly Used In The Manufacture of Various Parts for The Automotive, Boiler, Furniture, Fuel Pipes and Air Conditioner Industries and Many More By Providing Solutions Which Maximize The Quality And Production Efficiency.

_________________________________________________________________________

Model: TM-60NC/CNC

Specification: 60mm(2.5")x2mm

Drive Mode: Mechanical

Technical: Tube End Forming

Business Type: Professoinal Manufacture

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 20 Days Dated From Deposit Received

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

TM-60NC Type 2 Station Press Pipe Edge Shrinkage Docking Tube End Forming Machine

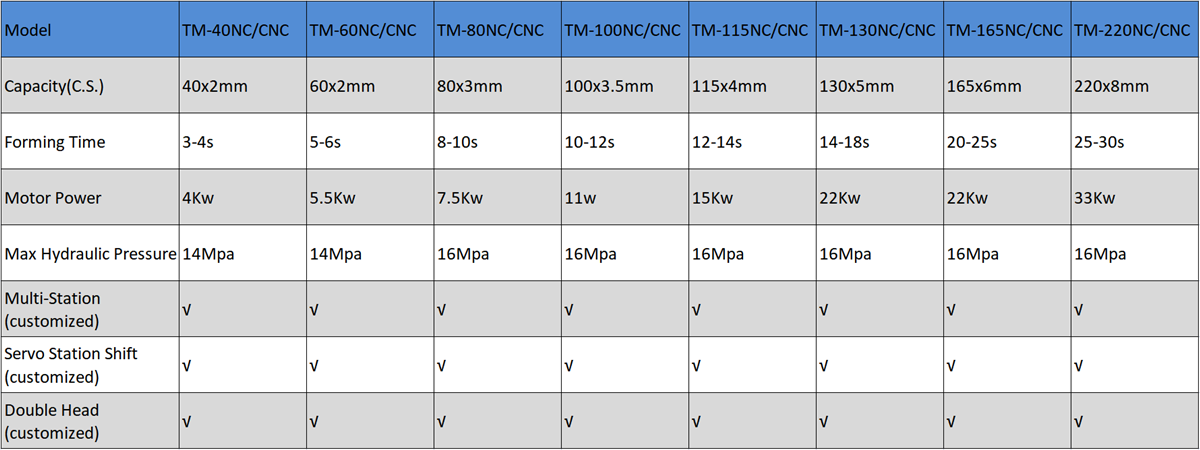

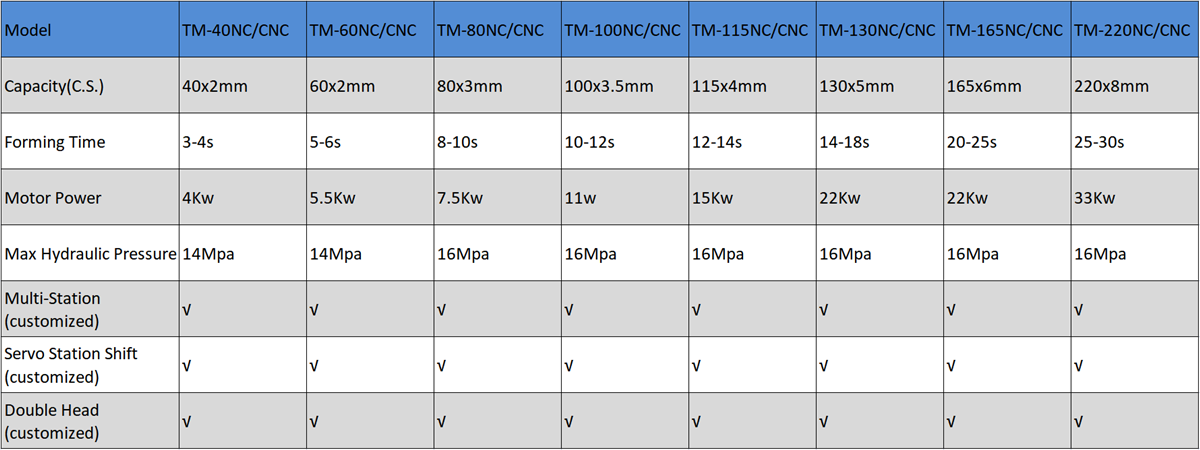

Main Technical Parameters Sheet

Brief Introduction on Pipe Edge Shrinkage Docking Tube End Forming Machine

SLS TM-60NC Type 2 Station Press Pipe Edge Shrinkage Docking Tube End Forming Machine Is a Kind of High Efficiency, Automatic Machine. It Can Be Do Different Types of End Forming as Reduction, Expansion, Beads, Flare and Thickening. Each of These Categories Has Special Requirements and Is Used In A Variety of Applications. It Is Controlled By Hydraulic and Electricity At The Same Time. It Combines Easy-to-Use Operation with High End Forming Accuracy and Cost Effectiveness. Choose From Semi-Automatic or Full Automatic with Auto Loading Pipe End Forming Machine to Best Meet Your Level of Production.

Features on Pipe Edge Shrinkage Docking Tube End Forming Machine

● Touch Screen or Human Interface Offers Easy Access to Auto and Manual Operating Modes.

● All The Parts Are Made Under Very Strict Quality Control, So The Quality of Machine Is In High Level and The Specification Is Standardized.

● Equipped with Emergency Stop Device.

● Both Manual and Automatic Operations Are Available.

● Tube Clamping and End Forming Driven by Hydraulic.

● Suitable for The Shrinking for Various Metal Pipes with Different Material and Different Shape.

● Forming Shapes Can Be Convex, Concave, Sectional, Long & Flat, Square, V-Shape, Open Elbow, Flat Elbow...Etc.

● The Design of The Tooling Help Customer Easy to Change.

● The Design of The Tooling Varies with Work-Piece & Customers Requirements.

● Water or Fan Cooling System Ensures The Equipment Long-Time Work Stably Under The High Temperature.

● Foot Pedal Cycle Start.

● Optional:An Additional Feeding System Can Be Added to The Machine. The Operating Security Is Greatly Increased Because The Operators Just Do The Unloading

& Collecting Job of Finished Pipes.

● Optional:Multi Station Can Be Added to The Machine Based on Detailed Forming Requirement.

● Optional: Multi Station Shifting Can Be Chosen As Servo(Electrical) or Hydraulic Control.

● Optional: Double Head Can Be Added to The Machine Based on Detailed Forming Requirement.

Main Application

Packaging & Shipping

Contact Us

TM-60NC Type 2 Station Press Pipe Edge Shrinkage Docking Tube End Forming Machine

Main Technical Parameters Sheet

Brief Introduction on Pipe Edge Shrinkage Docking Tube End Forming Machine

SLS TM-60NC Type 2 Station Press Pipe Edge Shrinkage Docking Tube End Forming Machine Is a Kind of High Efficiency, Automatic Machine. It Can Be Do Different Types of End Forming as Reduction, Expansion, Beads, Flare and Thickening. Each of These Categories Has Special Requirements and Is Used In A Variety of Applications. It Is Controlled By Hydraulic and Electricity At The Same Time. It Combines Easy-to-Use Operation with High End Forming Accuracy and Cost Effectiveness. Choose From Semi-Automatic or Full Automatic with Auto Loading Pipe End Forming Machine to Best Meet Your Level of Production.

Features on Pipe Edge Shrinkage Docking Tube End Forming Machine

● Touch Screen or Human Interface Offers Easy Access to Auto and Manual Operating Modes.

● All The Parts Are Made Under Very Strict Quality Control, So The Quality of Machine Is In High Level and The Specification Is Standardized.

● Equipped with Emergency Stop Device.

● Both Manual and Automatic Operations Are Available.

● Tube Clamping and End Forming Driven by Hydraulic.

● Suitable for The Shrinking for Various Metal Pipes with Different Material and Different Shape.

● Forming Shapes Can Be Convex, Concave, Sectional, Long & Flat, Square, V-Shape, Open Elbow, Flat Elbow...Etc.

● The Design of The Tooling Help Customer Easy to Change.

● The Design of The Tooling Varies with Work-Piece & Customers Requirements.

● Water or Fan Cooling System Ensures The Equipment Long-Time Work Stably Under The High Temperature.

● Foot Pedal Cycle Start.

● Optional:An Additional Feeding System Can Be Added to The Machine. The Operating Security Is Greatly Increased Because The Operators Just Do The Unloading

& Collecting Job of Finished Pipes.

● Optional:Multi Station Can Be Added to The Machine Based on Detailed Forming Requirement.

● Optional: Multi Station Shifting Can Be Chosen As Servo(Electrical) or Hydraulic Control.

● Optional: Double Head Can Be Added to The Machine Based on Detailed Forming Requirement.

Main Application

Packaging & Shipping

Contact Us