+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Our Manual Metal Pipe Tube Tapering Machine is a equipment used to process metal round tubes into coned shaped. This machine has the characteristics of low noise, easy operation, high output and stable performance. The tool change is simple and metal pipes of different conical shapes can be processed and formed by the cooperation of corresponding tool designs. The processing time is short which greatly improved working efficiency and the surface of the finished product is smooth without scratches.

_________________________________________________________________________

Model: TF-38F (Manual Type)

Specification: 38mm(1.5")x1.2mm

Drive Mode: Mechanical

Technical: Cold Forming&Forging

Business Type: Professoinal Manufacture

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 20 Days Dated From Deposit Received

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

Manual Metal Pipe Tube Tapering Machine

Main Technical Parameters Sheet

Brief Introduction on Manual Metal Pipe Tube Tapering Machine

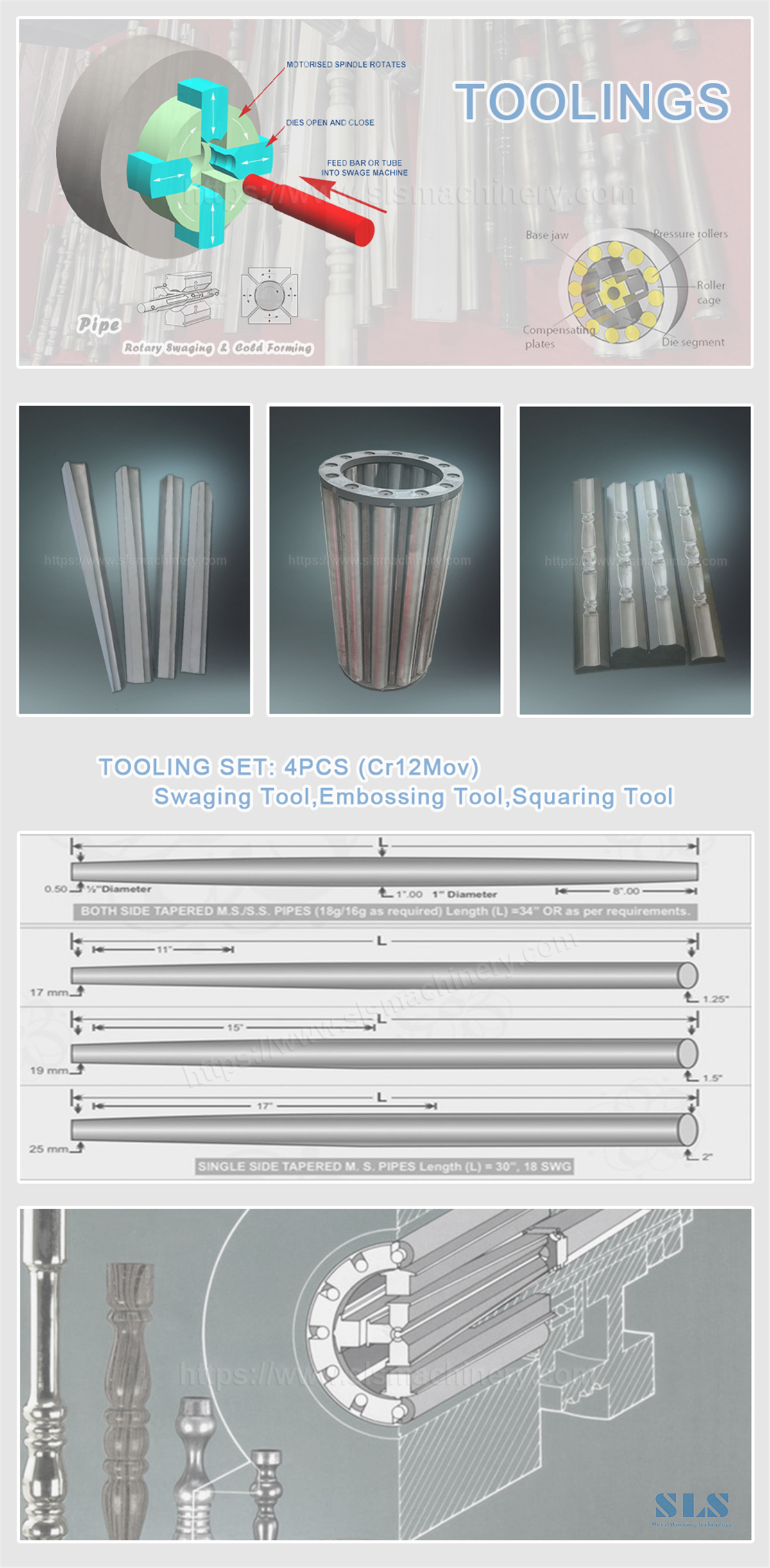

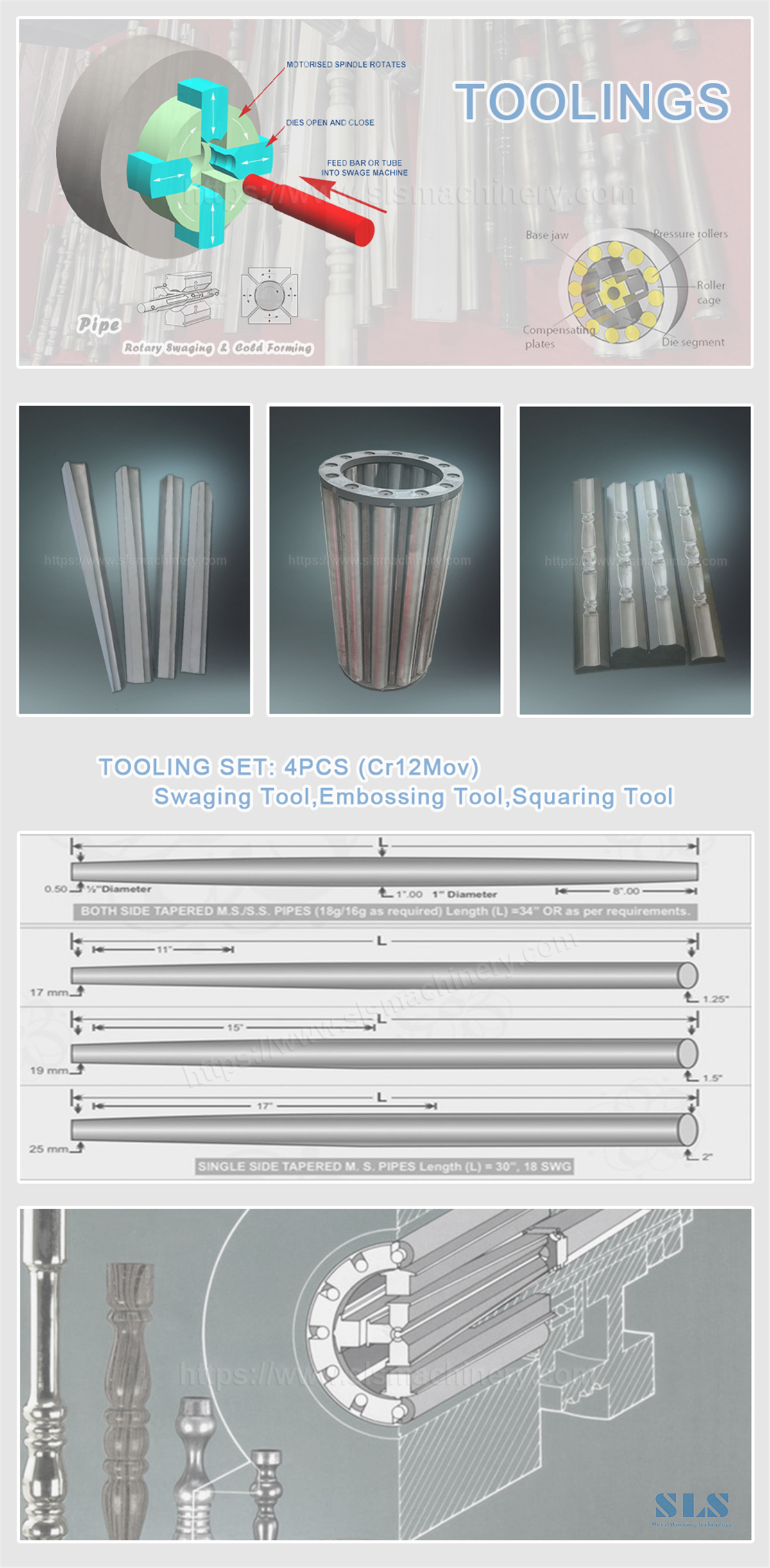

SLS Manual Metal Pipe Tube Tapering Machine Is a Special Kind of Pipe Cold Forming Machine.Pipe cone machine shaped pipe into tapered conical pipe which is determined by 4 or 6 dies, 4 dies are considered for small pipe diameters, and 6 dies are considered for big pipe diameters. The mold is mounted in the slot of the machine body, and the inside is inlaid with 4 or 6 wedge-shaped molds. The wedge-shaped tool manually installed in machine and after the motor rotates, it drives the mold to rotate and forging around the pipe. After manually feed forward to right position, the coned pipe got and can be pulled out.

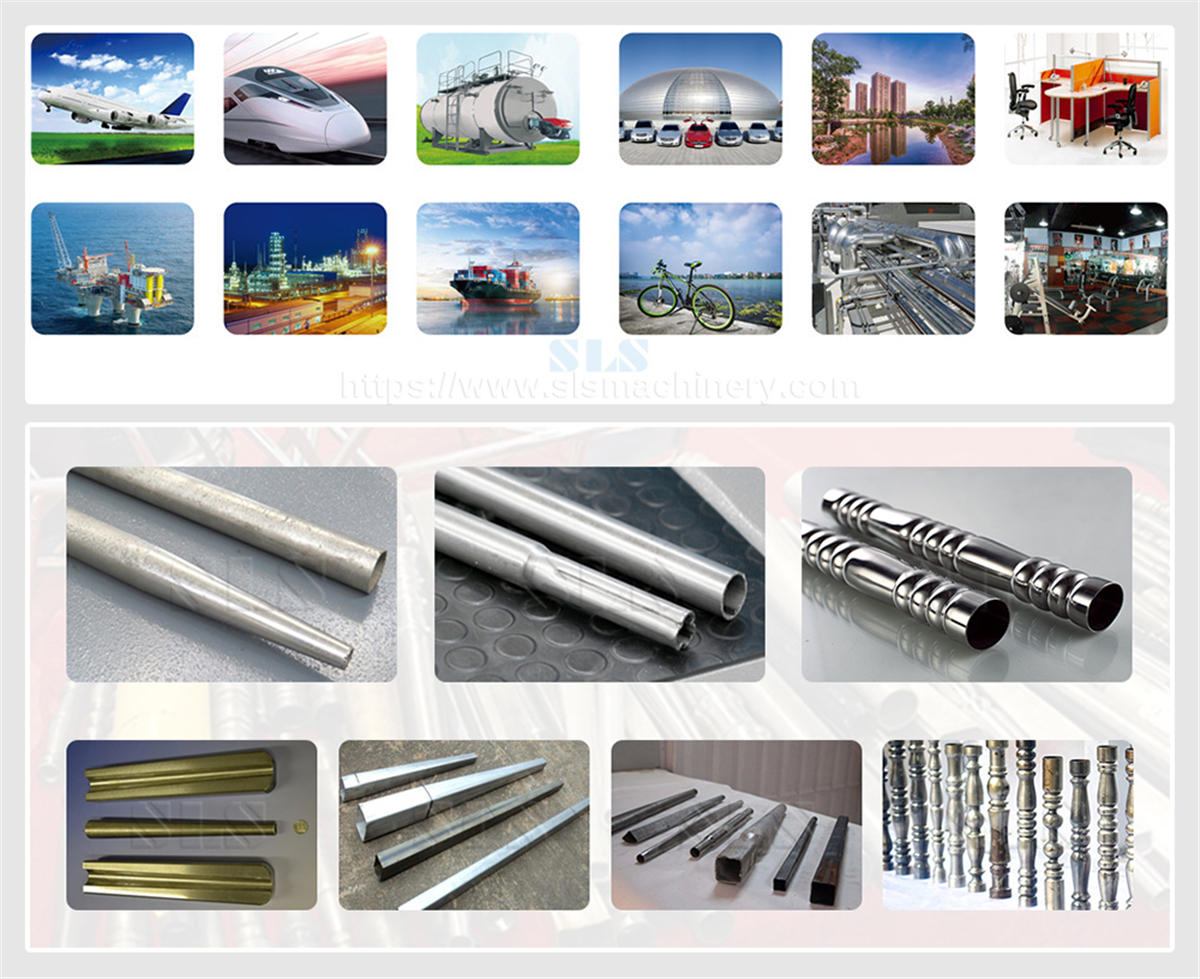

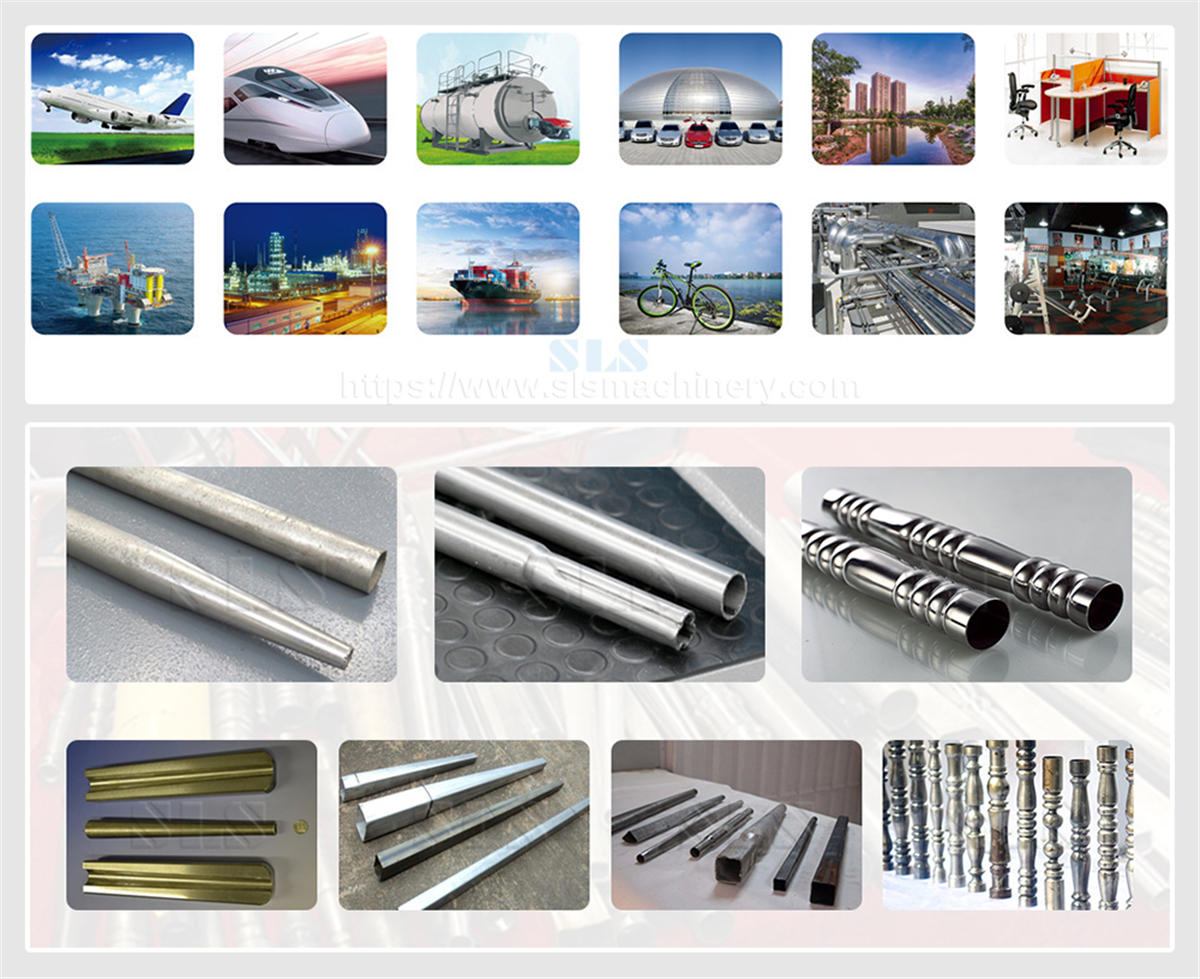

Widely used in furniture, anti-theft doors and windows, lighting, sporting goods, hardware processing, automobiles and other industries. Easy to say our tube tapering or one machine can make tables,chairs, sofas and bed legs, lampposts, stair handrails, fence handrails, light poles, golf clubs, baseball poles, fishing poles, decorative tubes etc.

Choose From a Manual, Semi-automatic, or Automatic Pipe Tapering Machine to Best Meet Your Level of Production.

Features on Manual Metal Pipe Tube Tapering Machine

Operation Panel Offers Easy Operation of Machine.

All The Parts Are Made Under Very Strict Quality Control, So The Quality of Machine is In High Level and The Specification is Standardized.

This model is manual type, so machine is manual loading, manual tapering and manual unloading

A High Quality Shaping Will Use Tools That Move The Dies In and Out, Offering as Many as 3000 Blows Per Minute to Hammer The Tube Into The Desired Shape.

Tapering Pipe Material: Steel, Stainless, Aluminum, Titanium and Brass...

The Design of The Tooling Help Customer Easy to Change.

The tapering angle same, cone length and cone size can be adjustable on same tool.

Machine mounted with positioning to meet different tapering length

Very Low Loise During Working: 75-85db.

CE&ISO 9001:2000.

Main Application

Packaging & Shipping

Contact Us

Manual Metal Pipe Tube Tapering Machine

Main Technical Parameters Sheet

Brief Introduction on Manual Metal Pipe Tube Tapering Machine

SLS Manual Metal Pipe Tube Tapering Machine Is a Special Kind of Pipe Cold Forming Machine.Pipe cone machine shaped pipe into tapered conical pipe which is determined by 4 or 6 dies, 4 dies are considered for small pipe diameters, and 6 dies are considered for big pipe diameters. The mold is mounted in the slot of the machine body, and the inside is inlaid with 4 or 6 wedge-shaped molds. The wedge-shaped tool manually installed in machine and after the motor rotates, it drives the mold to rotate and forging around the pipe. After manually feed forward to right position, the coned pipe got and can be pulled out.

Widely used in furniture, anti-theft doors and windows, lighting, sporting goods, hardware processing, automobiles and other industries. Easy to say our tube tapering or one machine can make tables,chairs, sofas and bed legs, lampposts, stair handrails, fence handrails, light poles, golf clubs, baseball poles, fishing poles, decorative tubes etc.

Choose From a Manual, Semi-automatic, or Automatic Pipe Tapering Machine to Best Meet Your Level of Production.

Features on Manual Metal Pipe Tube Tapering Machine

Operation Panel Offers Easy Operation of Machine.

All The Parts Are Made Under Very Strict Quality Control, So The Quality of Machine is In High Level and The Specification is Standardized.

This model is manual type, so machine is manual loading, manual tapering and manual unloading

A High Quality Shaping Will Use Tools That Move The Dies In and Out, Offering as Many as 3000 Blows Per Minute to Hammer The Tube Into The Desired Shape.

Tapering Pipe Material: Steel, Stainless, Aluminum, Titanium and Brass...

The Design of The Tooling Help Customer Easy to Change.

The tapering angle same, cone length and cone size can be adjustable on same tool.

Machine mounted with positioning to meet different tapering length

Very Low Loise During Working: 75-85db.

CE&ISO 9001:2000.

Main Application

Packaging & Shipping

Contact Us