+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

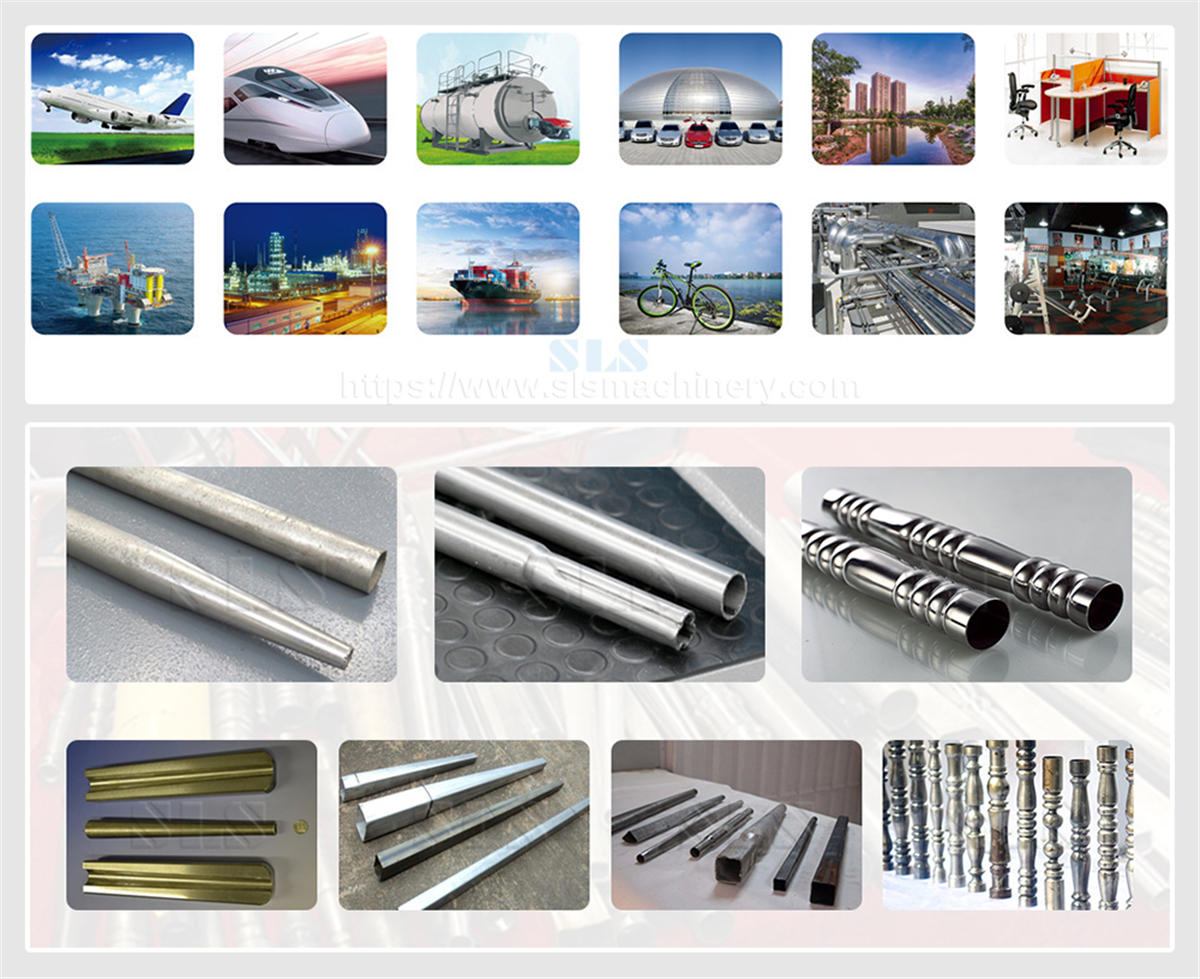

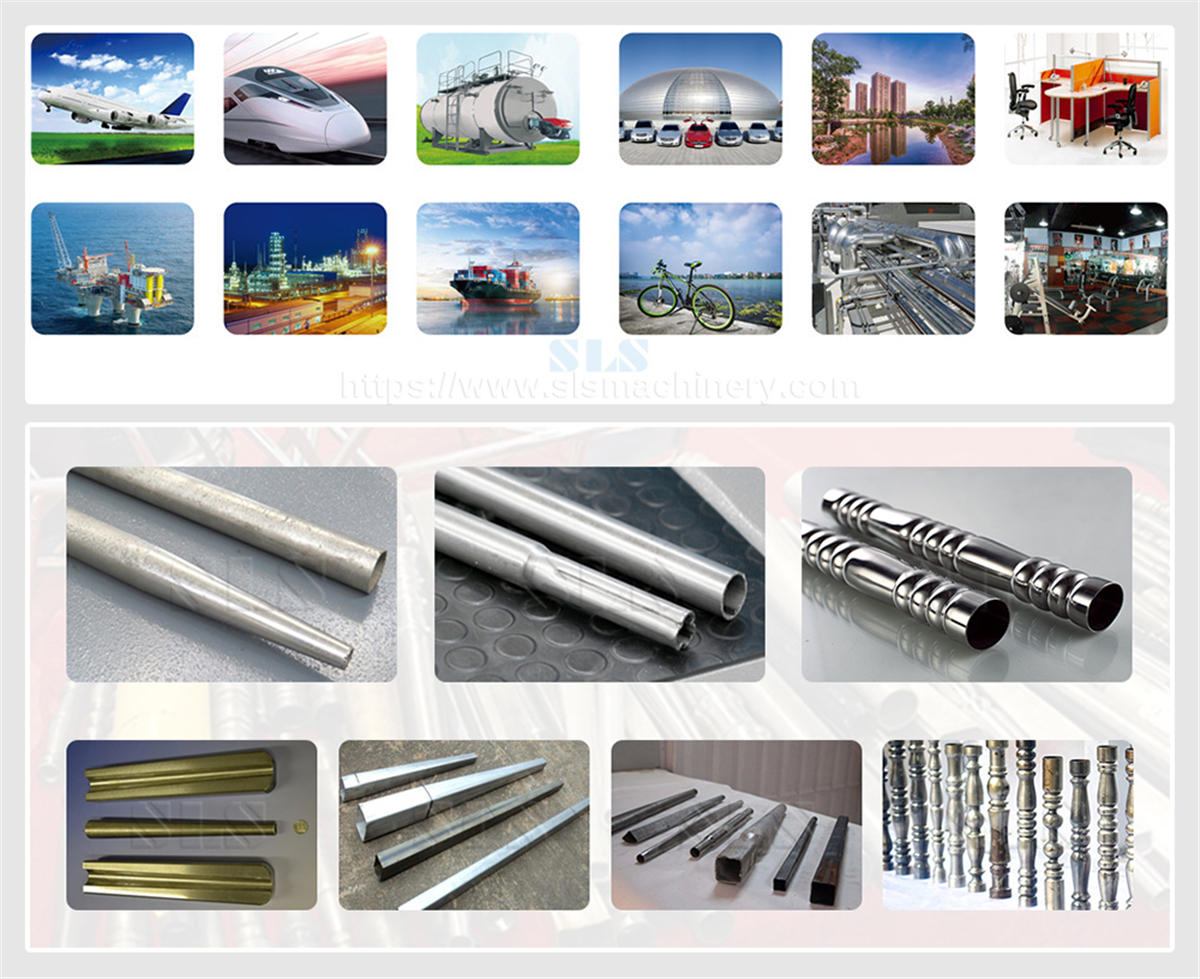

What is a pipe tapering machine? This is a kind of pipe cone machine or tube swaging machine that helps to reduce the diameter of tubes gradually. Applications for this machine range from shipbuilding,naval,building,construction, steel and automotive etc... To operate this machine, you first feed the tube into swaging head automatically or manually. No matter which kind of feed mode you choose, it won't make a noticeably different effect on product.

_________________________________________________________________________

Model: TF-76Y (Auto Feed Type)

Specification: 76mm(3")x2.5mm

Drive Mode: Mechanical and Hydraulic

Technical: Cold Forming Type

Business Type: Professoinal Manufacture

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 35-40 Days Dated From Deposit Received

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

Auto Feeding Pipe Shaping And Forming Machines for Tapered Tubes

Main Technical Parameters Sheet

Brief Introduction on Auto Feeding Pipe Shaping And Forming Machines for Tapered Tubes

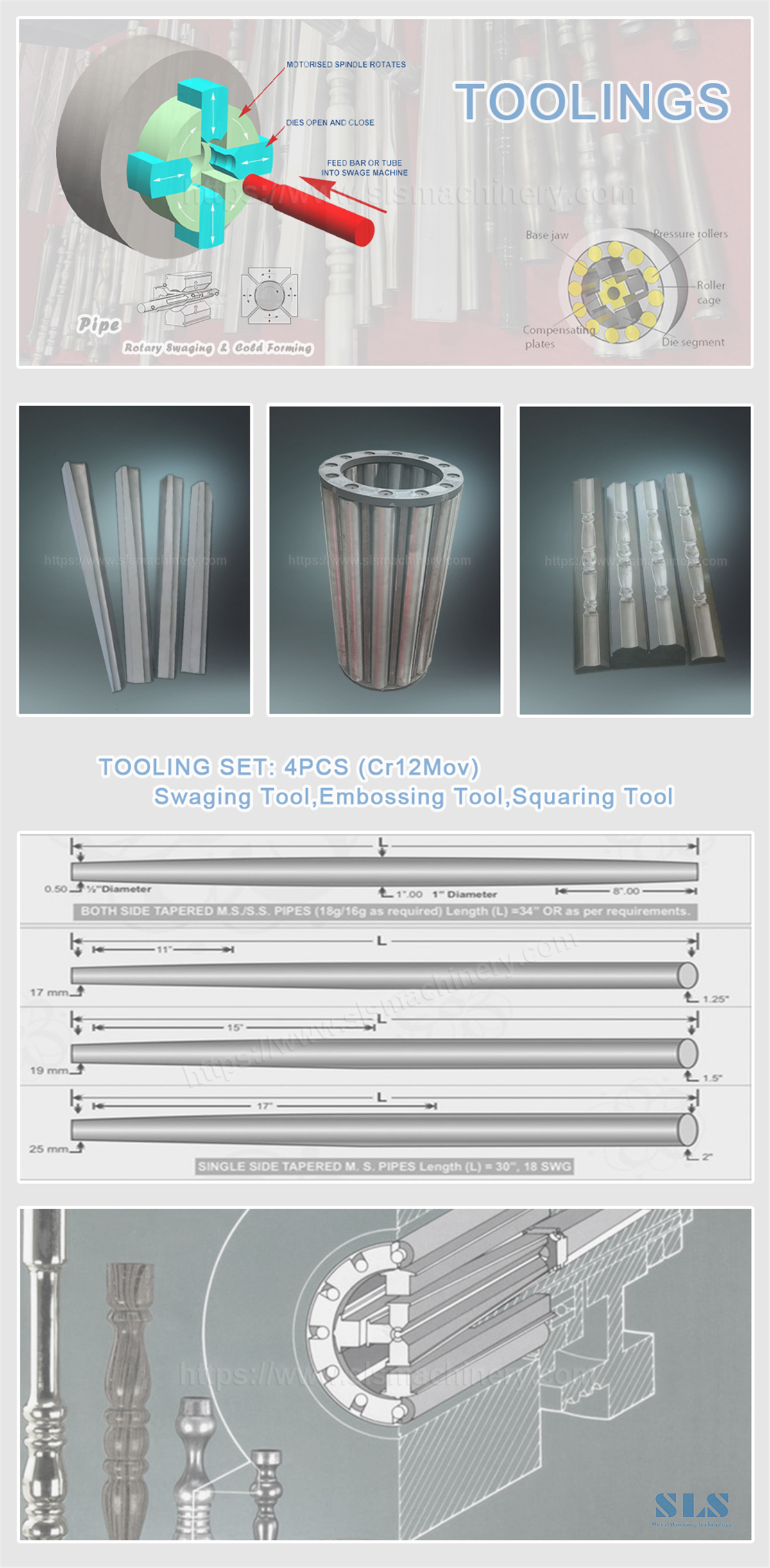

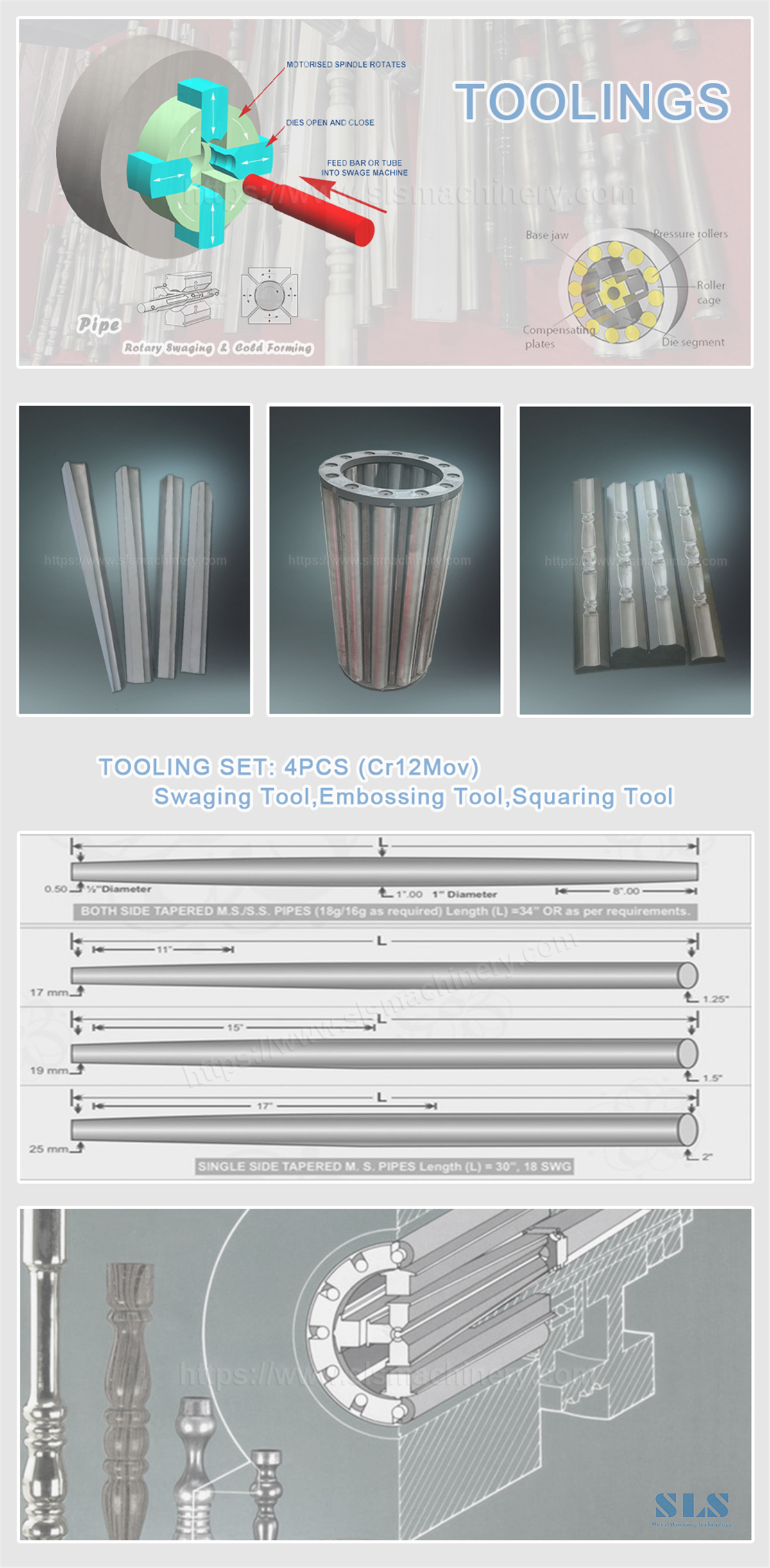

SLS Auto Feeding Pipe Shaping And Forming Machines for Tapered Tubes. The external tapering shape of the pipe is determined by the tool which is inset in the slot of the machine body, and the inside is inlaid with 4 pieces of wedge-shaped iron. The wedge-shaped iron manually adjusts the extrusion angle before extrusion. After the motor rotates, it drives the tool around the pipe and finally get desired shape. Tool is the very important part of machine which quality is determined by four key aspects as the design of the mold,the material of the mold, the processing of the mold, and the heat treatment of the mold.In the mold production process, pay attention to the requirements of the four aspects to make high level quality mold and machine.

Choose From a Manual, Semi-automatic, or Automatic Pipe Tapering Machine to Best Meet Your Level of Production.

Features on Auto Feeding Pipe Shaping And Forming Machines for Tapered Tubes

Machine operation very simple which low requirement on worker

All The Parts Are Made Under Very Strict Quality Control, So The Quality of Machine Is in High Level and The Specification is Standardized.

Manual Pipe Loading, Automatic Pipe Feeding Automatic Mechanical pipe shaping and forming

The design and structure of the mechanical equipment are reasonable, solid and reliable.

The overall body is smooth and beautiful!

The equipment saves power and has a long lifespan.

Available Pipe Material: Steel, Stainless, Aluminum, Titanium and Brass...

The Design of The Tooling Help Customer Easy to Change.

The operation is stable to make your operation safer and more reliable!

Low Noise to make worker feel comfortable.

ISO 9001:2000.

Main Application

Packaging & Shipping

Contact Us

Auto Feeding Pipe Shaping And Forming Machines for Tapered Tubes

Main Technical Parameters Sheet

Brief Introduction on Auto Feeding Pipe Shaping And Forming Machines for Tapered Tubes

SLS Auto Feeding Pipe Shaping And Forming Machines for Tapered Tubes. The external tapering shape of the pipe is determined by the tool which is inset in the slot of the machine body, and the inside is inlaid with 4 pieces of wedge-shaped iron. The wedge-shaped iron manually adjusts the extrusion angle before extrusion. After the motor rotates, it drives the tool around the pipe and finally get desired shape. Tool is the very important part of machine which quality is determined by four key aspects as the design of the mold,the material of the mold, the processing of the mold, and the heat treatment of the mold.In the mold production process, pay attention to the requirements of the four aspects to make high level quality mold and machine.

Choose From a Manual, Semi-automatic, or Automatic Pipe Tapering Machine to Best Meet Your Level of Production.

Features on Auto Feeding Pipe Shaping And Forming Machines for Tapered Tubes

Machine operation very simple which low requirement on worker

All The Parts Are Made Under Very Strict Quality Control, So The Quality of Machine Is in High Level and The Specification is Standardized.

Manual Pipe Loading, Automatic Pipe Feeding Automatic Mechanical pipe shaping and forming

The design and structure of the mechanical equipment are reasonable, solid and reliable.

The overall body is smooth and beautiful!

The equipment saves power and has a long lifespan.

Available Pipe Material: Steel, Stainless, Aluminum, Titanium and Brass...

The Design of The Tooling Help Customer Easy to Change.

The operation is stable to make your operation safer and more reliable!

Low Noise to make worker feel comfortable.

ISO 9001:2000.

Main Application

Packaging & Shipping

Contact Us