+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

SLS 50NC Type C Or U Shape Bending Two Tubes Together Double Head Pipe Bender Machine.The double head hydraulic pipe bending machine is a high machine which can be capable of performing two bends bending at the same time. Because of two bends simultaneous feature and advantage, it is ideal for high-speed bending of symmetrical tubular parts. Both our DB-38NC and DB-50NC are NC controlled and capable of bending multiple tubes at once. The bend angle can be adjusted to bend at the same angle or two separate angles. They are commonly used in industries such as car seat frames, furniture, handles, hardware or parts that require symmetrical bending.

_________________________________________________________________________

Model: DB-50NC

Specification: 50mm(2")x2mm

Drive Mode: Electric + Hydraulic

Suit Bending: 2D/3D Bend

Business Type: Professoinal Manufacturer

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 35 Days Dated From Deposit Received

Contact us :info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

50NC Type C Or U Shape Bending Two Tubes Together Double Head Pipe Bender Machine

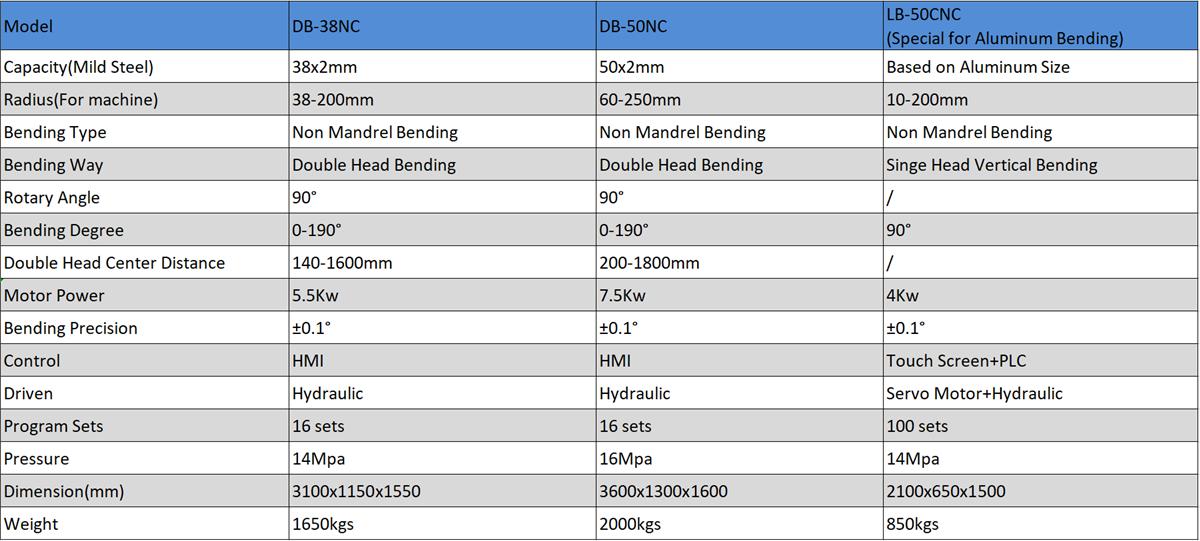

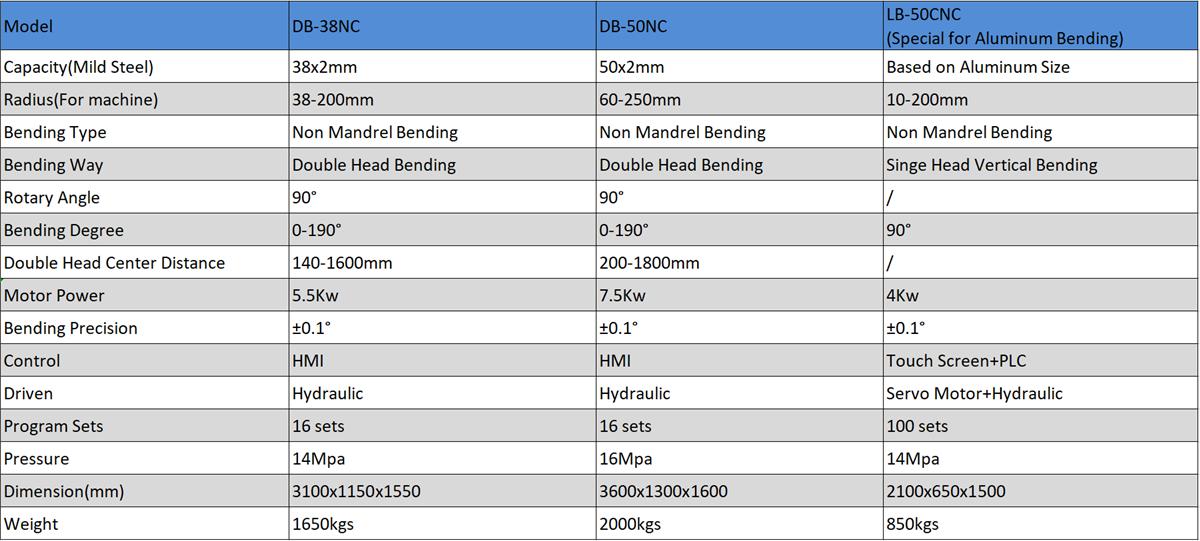

Main Technical Parameters Sheet

Brief Introduction on Double Head Pipe Bender Machine

SLS 50NC Type C Or U Shape Bending Two Tubes Together Double Head Pipe Bender Machine.Double head bending will give you the change to be up to 8 times faster than a standard single head mandrill bender,it will provide maximum productivity for your job. The single-head pipe bender can only bend one bend at a time, while the twin-head pipe bender can bend both ends of the pipe at the same time, which is especially suitable for symmetrical pipe bending. The double-head bending is a non mandrel bending machine. The principle is that the bending die hold on its position, and after the clamp die clamp the tube, it moves in a circular motion winding the center of the bending die to form the pipe into the desired shape. However, this bending process has certain restrictions on the size and bending radius of the pipe, and is more suitable for small pipe diameters with a bending radius of 3-5D. Depending on the diameter of the pipe, the tools can be designed to bend 2-4 pipes at the same time. The two head pipe bender has high flexibility, it can work simultaneously at both ends, or work separately at both ends. It adopts NC control system, the setting is simple and easy to understand, and it is easy to use. It is the best choice for high-efficiency non mandrel bending.

Features on Double Head Pipe Bender Machine

Automatic Hydraulic Double Head Bending.

Standard 90∘head rotation for 3D bending

Adjustable bending angle from 0 to 180 degrees

Fixed bending die for easy placement of tube in place prior to bending

The distance between two heads is 200mm to 1800mm

Standard 90∘head rotation for 3D bending

The distance between two heads is 200mm to 1800mm

Adjustable bending angle from 0 to 180 degrees

Different degrees of bending can be set on each side

Fixed bending die for easy placement of tube in place prior to bending

Simple and quick mold change

Simple and quick adjustment of elbow angle and center distance

Dies can be 2 or 3 depending on the pipe diameter.

Provides a water cooling system, which is convenient for users to control the oil temperature and ensures that the equipment can work stably for a long time under high temperature.

Available Pipe Material: Steel, Stainless, Aluminum, Titanium and Brass...

Available Pipe Shape: Round, Square, Rectangle, Oval, Solid Bar, Angle Iron, Aluminum Extrusions, Flat Stock and Other Profiles...

Electric: As Required (3 Phase 220V Or 380V Or 415V...)

Main Application

Packaging & Shipping

Contact Us

50NC Type C Or U Shape Bending Two Tubes Together Double Head Pipe Bender Machine

Main Technical Parameters Sheet

Brief Introduction on Double Head Pipe Bender Machine

SLS 50NC Type C Or U Shape Bending Two Tubes Together Double Head Pipe Bender Machine.Double head bending will give you the change to be up to 8 times faster than a standard single head mandrill bender,it will provide maximum productivity for your job. The single-head pipe bender can only bend one bend at a time, while the twin-head pipe bender can bend both ends of the pipe at the same time, which is especially suitable for symmetrical pipe bending. The double-head bending is a non mandrel bending machine. The principle is that the bending die hold on its position, and after the clamp die clamp the tube, it moves in a circular motion winding the center of the bending die to form the pipe into the desired shape. However, this bending process has certain restrictions on the size and bending radius of the pipe, and is more suitable for small pipe diameters with a bending radius of 3-5D. Depending on the diameter of the pipe, the tools can be designed to bend 2-4 pipes at the same time. The two head pipe bender has high flexibility, it can work simultaneously at both ends, or work separately at both ends. It adopts NC control system, the setting is simple and easy to understand, and it is easy to use. It is the best choice for high-efficiency non mandrel bending.

Features on Double Head Pipe Bender Machine

Automatic Hydraulic Double Head Bending.

Standard 90∘head rotation for 3D bending

Adjustable bending angle from 0 to 180 degrees

Fixed bending die for easy placement of tube in place prior to bending

The distance between two heads is 200mm to 1800mm

Standard 90∘head rotation for 3D bending

The distance between two heads is 200mm to 1800mm

Adjustable bending angle from 0 to 180 degrees

Different degrees of bending can be set on each side

Fixed bending die for easy placement of tube in place prior to bending

Simple and quick mold change

Simple and quick adjustment of elbow angle and center distance

Dies can be 2 or 3 depending on the pipe diameter.

Provides a water cooling system, which is convenient for users to control the oil temperature and ensures that the equipment can work stably for a long time under high temperature.

Available Pipe Material: Steel, Stainless, Aluminum, Titanium and Brass...

Available Pipe Shape: Round, Square, Rectangle, Oval, Solid Bar, Angle Iron, Aluminum Extrusions, Flat Stock and Other Profiles...

Electric: As Required (3 Phase 220V Or 380V Or 415V...)

Main Application

Packaging & Shipping

Contact Us