+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Our popular Semi Auto Pipe Taper Tube Cone Machine Making Funiture,the key function of tapering machine is to make home furniture, wrought iron accessories, lighting decorations, advanced indoor stairs, guardrail hardware and other metal accessories, etc.The biggest advantage over manual pipe cone machine is that it only needs one person to operate, which reduces labor efficiency.The work efficiency is improved, the taper speed is faster and the accuracy is high, and it can reduce labor costs and increase economic benefits.

_________________________________________________________________________

Model: TF-38Y (Semi Auto,Hydraulic)

Specification: 38mm(1.5")x1.2mm

Drive Mode: Mechanical + Hydraulic

Technical: Cold Taper

Business Type: Professoinal Manufacture

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 25-30 Days Dated From Deposit Received

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

Semi Auto Pipe Taper Tube Cone Machine Making Funiture Legs

Main Technical Parameters Sheet

Brief Introduction on Semi Auto Pipe Taper Tube Cone Machine Making Funiture Legs

SLS Semi Auto Pipe Taper Tube Cone Machine Making Funiture Legs Is a Special Kind of pipe tube cold taper machine.The operate of semi automatic pipe cone machine is very simple. Clamping the steel pipe on the fixture of the equipment, press the "start" button, and the mold will taper the steel pipe with the mechanical transmission until it reaches the required size and standard. Taper pipe processing is actually the process of driving the steel pipe to rotate through mechanical transmission. Our equipment adopts imported fixtures which have good clamping force and are not easy to be damaged. No phenomenon of left-right or front-back deflection or jumping during work.

Choose From a Manual, Semi-automatic, or Automatic Pipe Tapering Machine to Best Meet Your Level of Production.

Features on Semi-auto Copper Aluminum Metal Steel Pipe Tube Tapering Machine

Very easy for worker to manage or control to machine.

Machine mechanical parts with special high quality level.

Machine function as Manual Pipe Loading, Automatic Pipe Feeding into Machine head by Hydraulic, Automatic Mechanical Pipe Taper.

Different pipe material and pipe thickness will impact on taper result as well.

A High Quality Shaping Will Use Tools That Move The Dies In And Out, Offering As Many As 3000 Blows Per Minute to Hammer The Tube Into The Desired Shape.

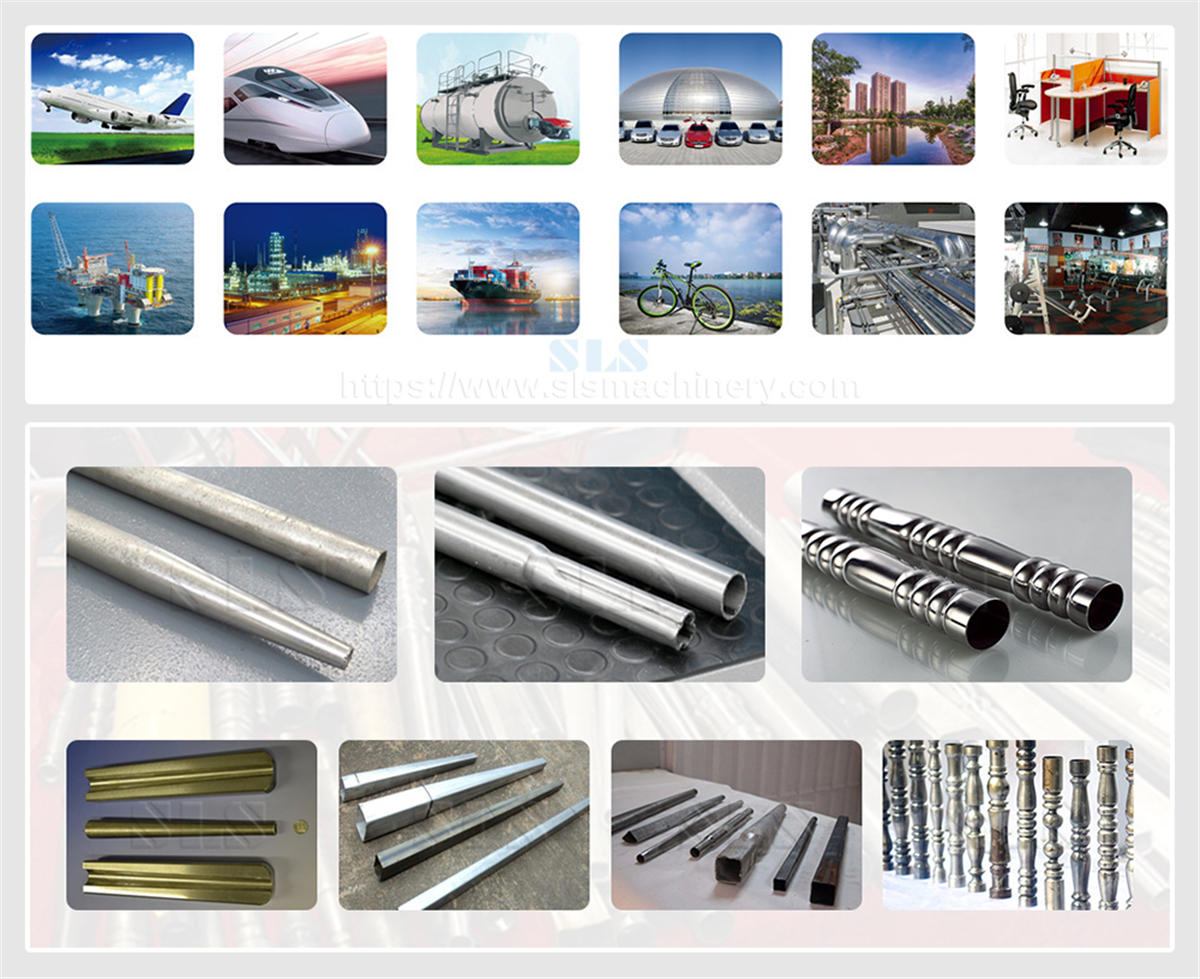

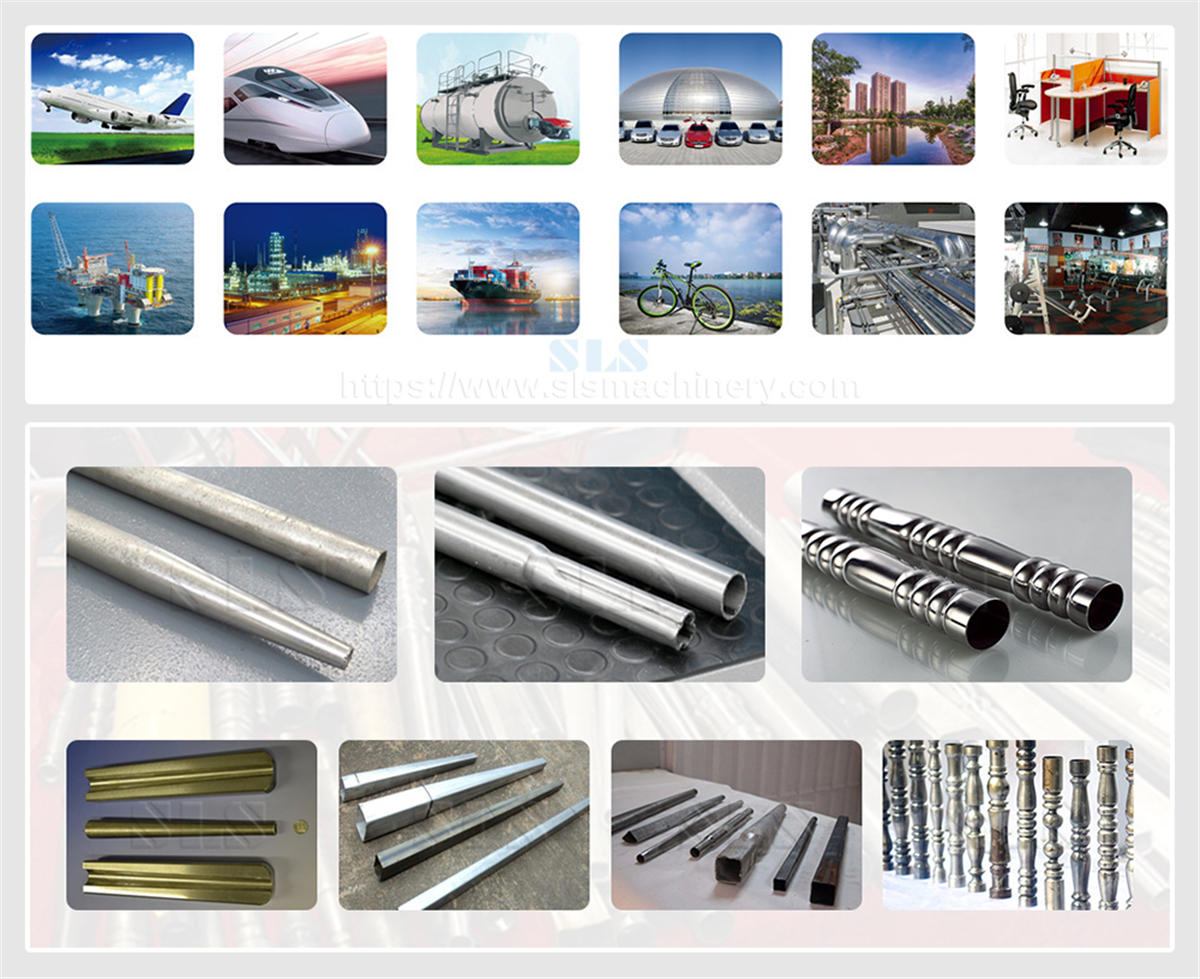

Available Pipe Material: Steel, Stainless, Aluminum, Titanium and Brass...

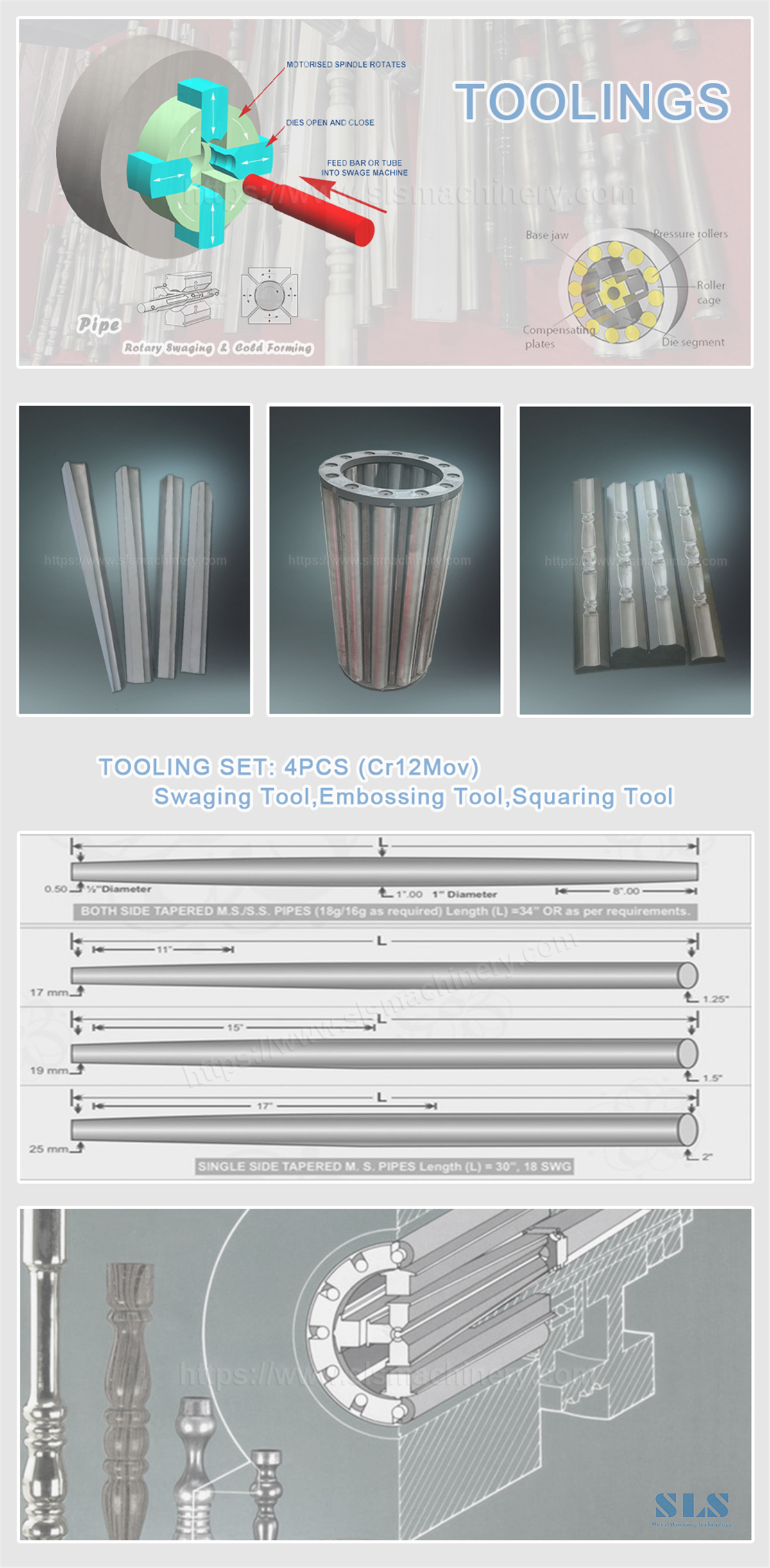

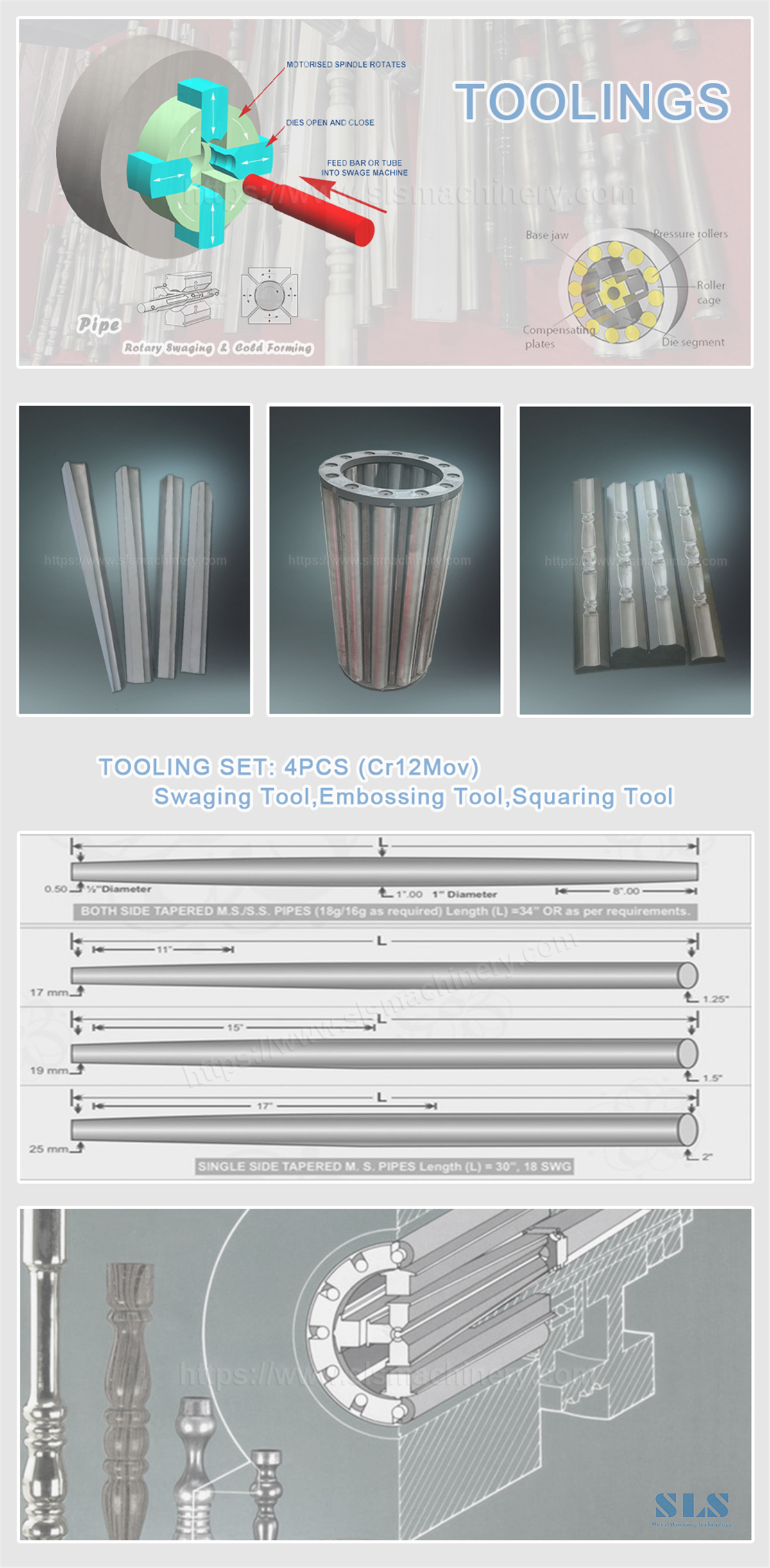

The Design of The Tooling Help Customer Easy to Change.

Low noisy to comfortable worker when operating machine.

CE Certificate.

Main Application

Packaging & Shipping

Contact Us

Semi Auto Pipe Taper Tube Cone Machine Making Funiture Legs

Main Technical Parameters Sheet

Brief Introduction on Semi Auto Pipe Taper Tube Cone Machine Making Funiture Legs

SLS Semi Auto Pipe Taper Tube Cone Machine Making Funiture Legs Is a Special Kind of pipe tube cold taper machine.The operate of semi automatic pipe cone machine is very simple. Clamping the steel pipe on the fixture of the equipment, press the "start" button, and the mold will taper the steel pipe with the mechanical transmission until it reaches the required size and standard. Taper pipe processing is actually the process of driving the steel pipe to rotate through mechanical transmission. Our equipment adopts imported fixtures which have good clamping force and are not easy to be damaged. No phenomenon of left-right or front-back deflection or jumping during work.

Choose From a Manual, Semi-automatic, or Automatic Pipe Tapering Machine to Best Meet Your Level of Production.

Features on Semi-auto Copper Aluminum Metal Steel Pipe Tube Tapering Machine

Very easy for worker to manage or control to machine.

Machine mechanical parts with special high quality level.

Machine function as Manual Pipe Loading, Automatic Pipe Feeding into Machine head by Hydraulic, Automatic Mechanical Pipe Taper.

Different pipe material and pipe thickness will impact on taper result as well.

A High Quality Shaping Will Use Tools That Move The Dies In And Out, Offering As Many As 3000 Blows Per Minute to Hammer The Tube Into The Desired Shape.

Available Pipe Material: Steel, Stainless, Aluminum, Titanium and Brass...

The Design of The Tooling Help Customer Easy to Change.

Low noisy to comfortable worker when operating machine.

CE Certificate.

Main Application

Packaging & Shipping

Contact Us