+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Popular Easy Operate Hydraulic Swage Machine for Metal Pipes Tubes.This semi-automatic cone machine is specially developed for the production of furniture cones, such as chair legs, stool legs, sofa legs, table legs, etc. . . It specializes in the production and processing of metal furniture legs, which have the characteristics of high output and stable performance. The forming time of the product workpiece is short, the surface of the production and processing is smooth, and the product workpiece has no scars. The mold of the equipment is easy to replace, and with the cooperation of corresponding molds, metal pipes of different shapes can be produced and processed to meet different requirements.

_________________________________________________________________________

Model: TF-50Y (Hydraulic)

Specification: 50mm(2")x1.5mm

Drive Mode: Hydraulic and Mechanical

Technical: Cold Swage Type

Business Type: Professoinal Manufacture

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 25-30 Days Dated From Deposit Received

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

Popular Easy Operate Hydraulic Swage Machine for Metal Pipes Tubes

Main Technical Parameters Sheet

Brief Introduction on Hydraulic Swage Machine for Metal Pipes Tubes

SLS Popular Easy Operate Hydraulic Swage Machine for Metal Pipes Tubes Is a Special Kind of Tube Cold Taper Swage Machine.Driven by the motor, the taper shrink tube oil pump outputs hydraulic oil to push the plunger in the tapering cylinder to move forward, so that the plunger and the four inner taper sleeves on the front cylinder head push the mold base with symmetrical tapered surface to shrink radially , to realize the tapering of the mould on the rubber hose. When the shrinkage reaches the setting value of the scale, the tapering stops automatically. After the electromagnetic reversing valve is reversed, the hydraulic oil enters the two mold opening cylinders, pushing the crimping plunger to move in the opposite direction, and the mold base drives the module to recover under the action of the spring. The fuel tank of the equipment is welded with a new generation of carbon dioxide electric welding to ensure that there is no residue, no oil leakage, and no welding slag in the fuel tank; the weld of the fuel tank has no cracks, no slag inclusions, continuous welding and other defects.

Features on Tapered Pipe Tube Diameter Reducing Machine

● Operation Panel Offers Easy Operation of Machine.

● All The Parts Are Made Under Very Strict Quality Control, So The Quality of Machine Is in High Level and The Specification is Standardized.

● Machine Featured as Manual Pipe Loading, Automatic Pipe Feeding Into Machine by Hydraulic, Automatic Mechanical Rotary Swaging.

● A High Quality Shaping Will Use Tools That Move The Dies In And Out, Offering As Many As 3000 Blows Per Minute to Hammer The Tube Into The Desired Shape.

● The Thickness of The Pipe and The Strength of The Material To Be Tapered Will Also Impact How The Materials Should Be Prepared to Create a Clean Tapered Edge.

● Available Pipe Material: Different types of metal pipes.

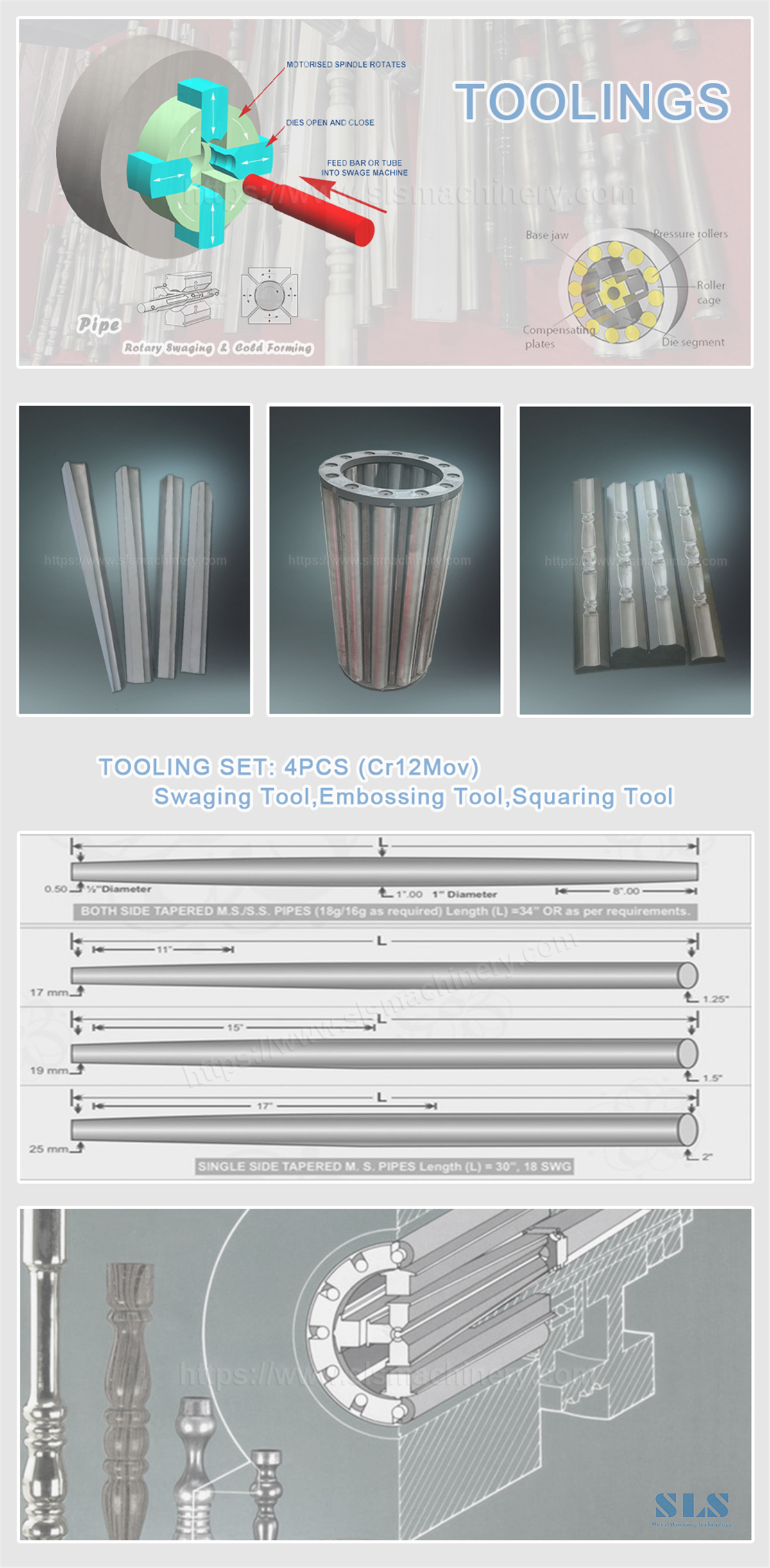

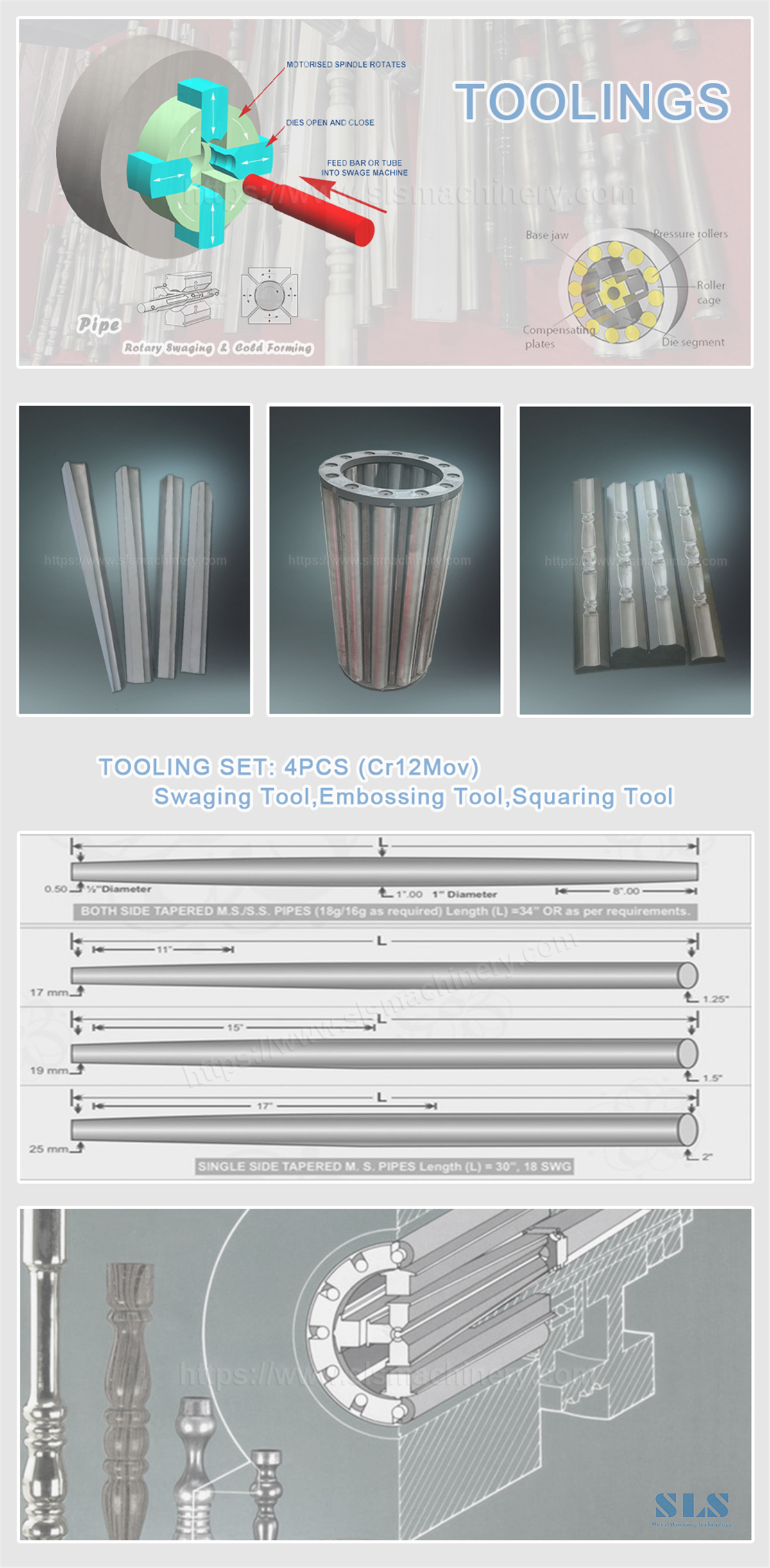

● The Design of The Tooling Help Customer Easy to Change.

● Very Low Noise During Working: 75-85db.

● CE Certificate.

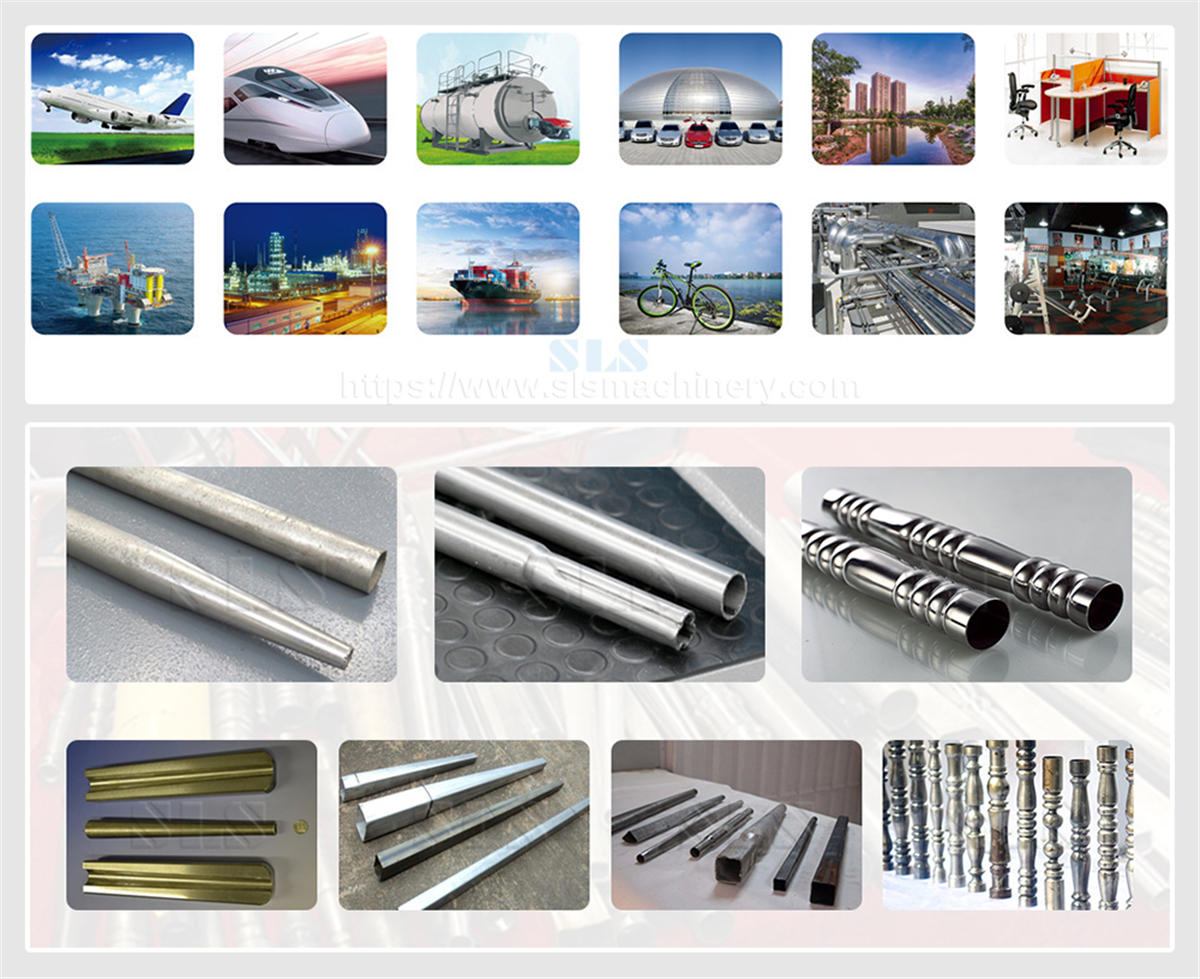

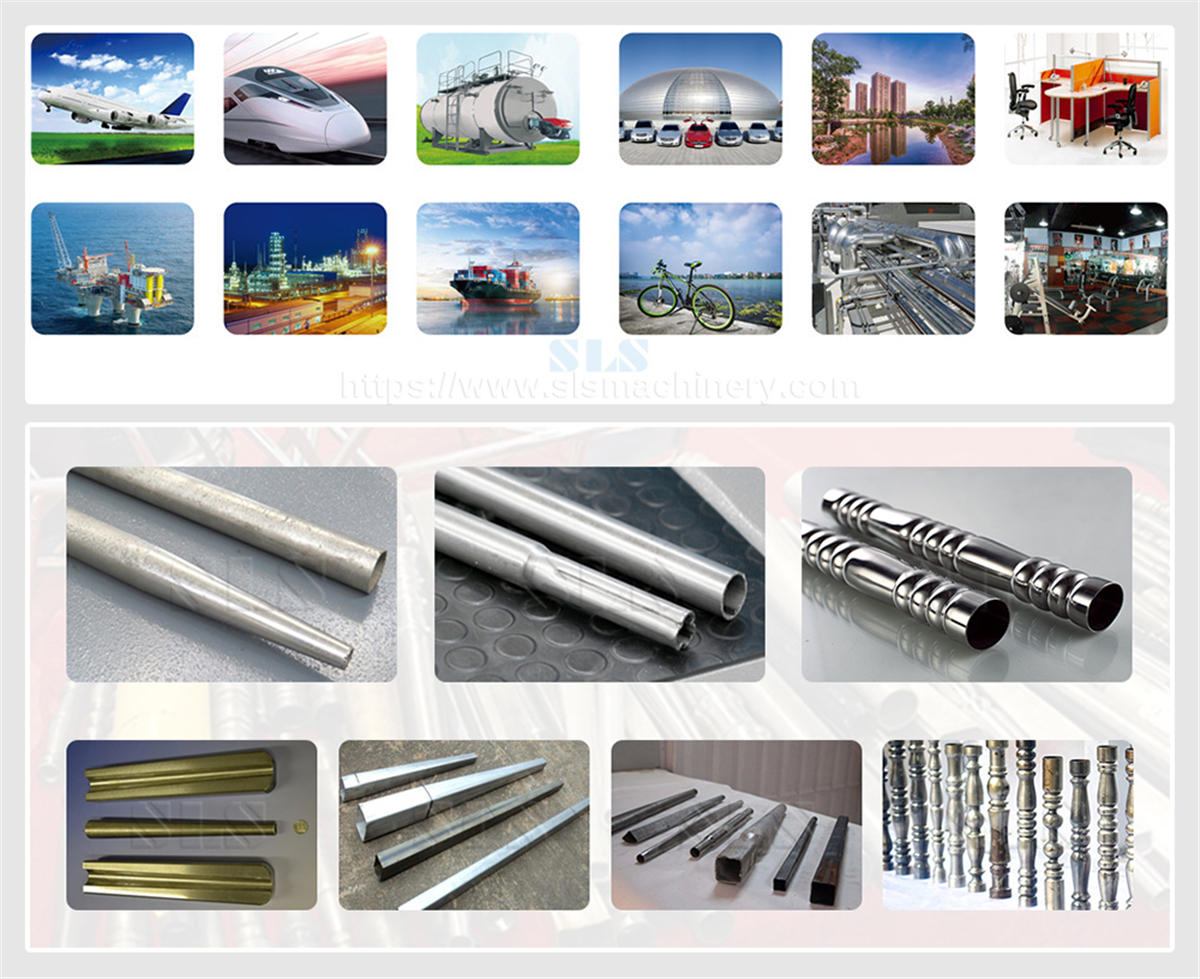

Main Application

Packaging & Shipping

Contact Us

Popular Easy Operate Hydraulic Swage Machine for Metal Pipes Tubes

Main Technical Parameters Sheet

Brief Introduction on Hydraulic Swage Machine for Metal Pipes Tubes

SLS Popular Easy Operate Hydraulic Swage Machine for Metal Pipes Tubes Is a Special Kind of Tube Cold Taper Swage Machine.Driven by the motor, the taper shrink tube oil pump outputs hydraulic oil to push the plunger in the tapering cylinder to move forward, so that the plunger and the four inner taper sleeves on the front cylinder head push the mold base with symmetrical tapered surface to shrink radially , to realize the tapering of the mould on the rubber hose. When the shrinkage reaches the setting value of the scale, the tapering stops automatically. After the electromagnetic reversing valve is reversed, the hydraulic oil enters the two mold opening cylinders, pushing the crimping plunger to move in the opposite direction, and the mold base drives the module to recover under the action of the spring. The fuel tank of the equipment is welded with a new generation of carbon dioxide electric welding to ensure that there is no residue, no oil leakage, and no welding slag in the fuel tank; the weld of the fuel tank has no cracks, no slag inclusions, continuous welding and other defects.

Features on Tapered Pipe Tube Diameter Reducing Machine

● Operation Panel Offers Easy Operation of Machine.

● All The Parts Are Made Under Very Strict Quality Control, So The Quality of Machine Is in High Level and The Specification is Standardized.

● Machine Featured as Manual Pipe Loading, Automatic Pipe Feeding Into Machine by Hydraulic, Automatic Mechanical Rotary Swaging.

● A High Quality Shaping Will Use Tools That Move The Dies In And Out, Offering As Many As 3000 Blows Per Minute to Hammer The Tube Into The Desired Shape.

● The Thickness of The Pipe and The Strength of The Material To Be Tapered Will Also Impact How The Materials Should Be Prepared to Create a Clean Tapered Edge.

● Available Pipe Material: Different types of metal pipes.

● The Design of The Tooling Help Customer Easy to Change.

● Very Low Noise During Working: 75-85db.

● CE Certificate.

Main Application

Packaging & Shipping

Contact Us