+86-181 0015 0701 +86-181 0015 0701 info@slsmachinery.com

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Our EF-50AC Type Portable Hand Held Tube End Deburring Pipe Chamfering Machine Also Know As Pipe Beveling Machine Is a Special Kind of Pipe End Smooth Machine. Chamfering Machine Can Be Have Single Head or Double Head One Which Meet Different Customer’S Requirement. The Controlling for The Machine At Pneumatic or Hydraulic According to Different Size, Material of Beveling. It Is Mainly Used In The Manufacture of Various Parts for The Automotive, Boiler, Furniture and Many More By Providing Solutions Which Maximize The Quality and Production Efficiency. We Keep Many Chamfering Machines In Stock for Quick Shipments.

_________________________________________________________________________

Model: EF-50AC

Specification: 50mm

Drive Mode: Electric + Pneumatic

Technical: Dry Chamfering

Business Type: Professoinal Manufacture

Payment: T/T,L/C,D/P,Western Union,MoneyGram

Lead Time: 25 Days Dated From Deposit Received

Contact us:info@slsmachinery.com

Wechat/Whatsapp:+86 18100150701

| Availability: | |

|---|---|

|

| |

EF-50AC Type Portable Hand Held Tube End Deburring Pipe Chamfering Machine

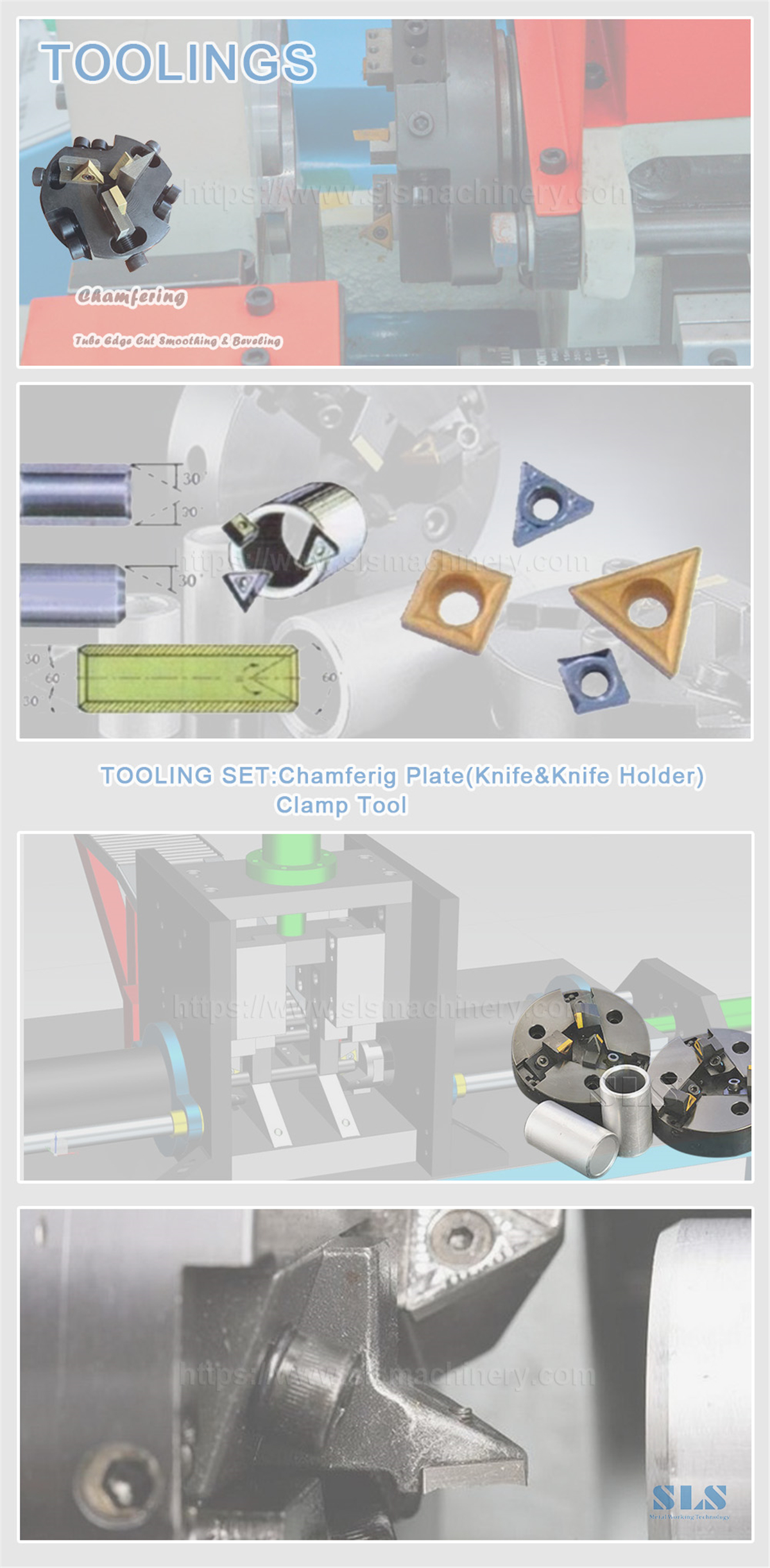

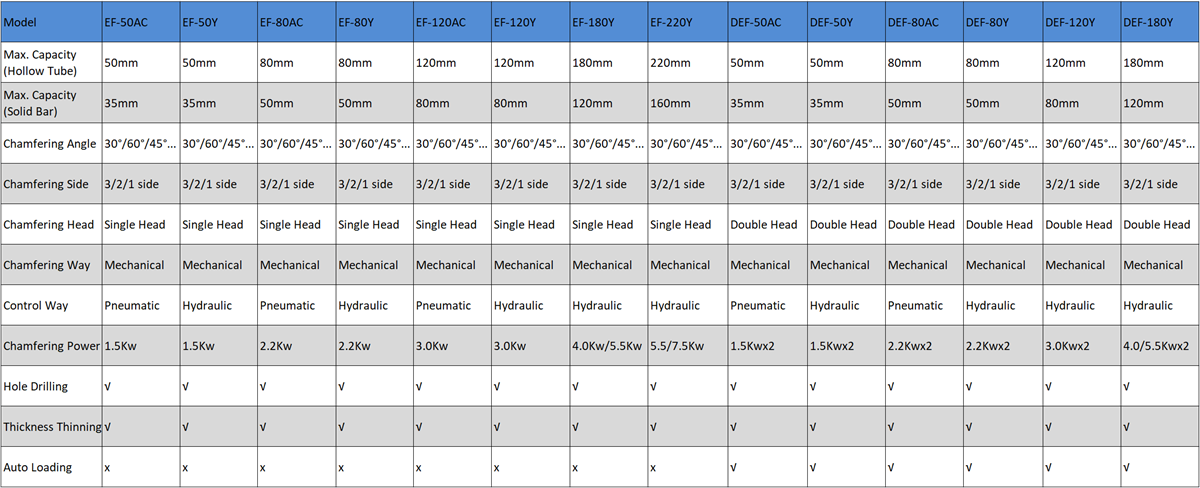

Main Technical Parameters Sheet

Brief Introduction on Tube End Deburring Pipe Chamfering Machine

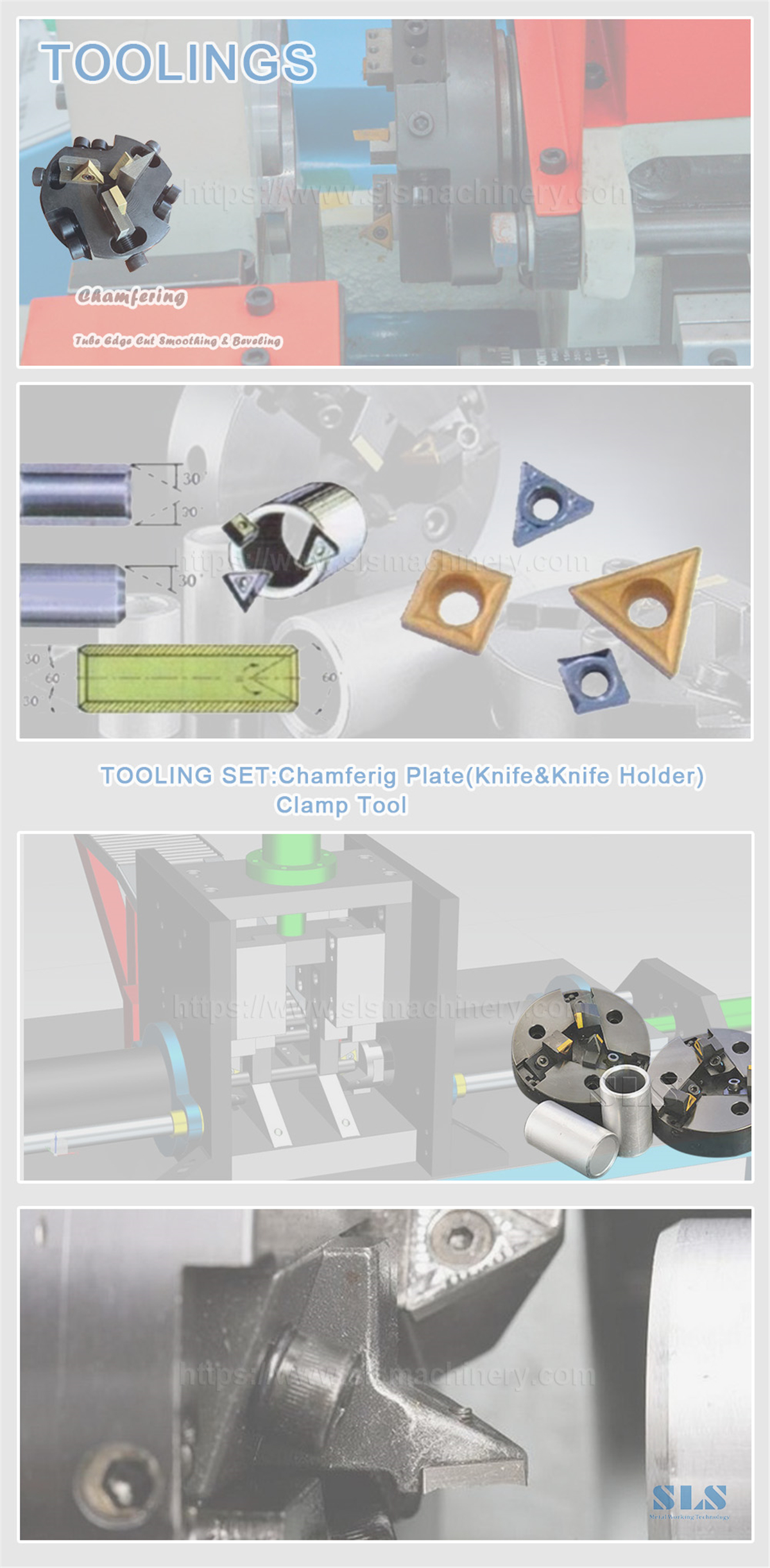

SLS EF-50AC Type Portable Hand Held Tube End Deburring Pipe Chamfering Machine Equipment a Kind of Semi-Automatic Single Head Machine with Manual Loading, Automatic Mechanical Chamfering and Automatic Clamping Driven By Pneumatic. Chamfering Work Can Be Expanded As Three Sides, Two Sides or Single Side Chamfering, Bore a Hole or Thickness Reducing. Chamfering Process Can Be Finished At One Time In Fast Speed and Accurate Chamfering Requirement. Sometimes Chamfering Is Defined As a Form of Bevel, and It Is Usually Processed At a 30,45 or 60 Degree Angle Between Two Adjacent Right-Angle Faces. Clamp Device and Knife Holder Are Precisely Designed for Ensure The Center Line Between Work-Piece and Knife Holder At The Same Level. Chamfering Length Can Be Adjusted Based on Specific Requirement.Choose From Semi-Automatic or Full Automatic with Auto Loading Tube Chamfering Machine to Best Meet Your Level of Production.

Features on Tube End Deburring Pipe Chamfering Machine

● Control Panel Offers Easy Access to Auto and Manual Operating Modes.

● All The Parts Are Made Under Very Strict Quality Control, So The Quality of Machine Is In High Level and The Specification Is Standardized.

● Equipped with Emergency Stop Device.

● A Circular Tube Modifies An Interior Angle, An External Angle and Flat Plane At One Time with Fastness and Precision.

● Automatic and Manual Working Mode Which Are Convenient for Adjusting The Machine, Mold and Chamfering Knife.

● Material Available: Carbon Steel, Stainless Steel, Copper, Aluminum...

● Chamfering Work Is Driven By Mechanical and Clamping Work Driven By Pneumatic.

● Clamp Device and Knife Holder Are Precisely Designed for Ensure The Center Line Between Workpiece and Knife Holder At The Same Level.

● Dual Feed Chamfer System:

First Speed------Fast Forward Movement Nearly to Tube End to Save The Time.

Second Speed---Infinitely Variable Forward Adjustable Chamfering Speed to Get Smooth Finish.

● The Design of The Tooling Help Customer Easy to Change.

● Foot Pedal Cycle Start.

● Optional: Double Head Can Be Added to The Machine Based on Detailed Chamfering Requirement.

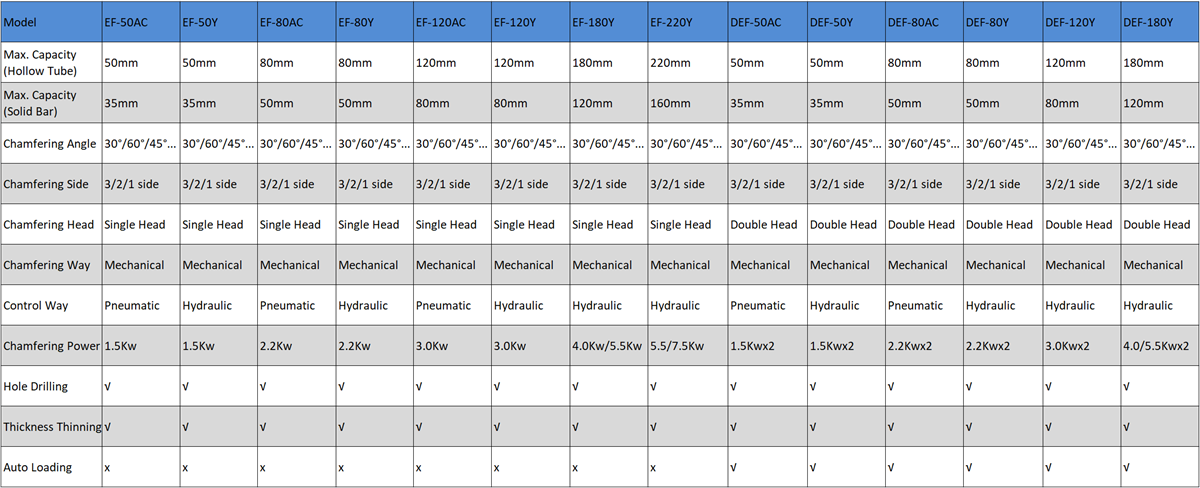

Main Application

Packaging & Shipping

Contact Us

EF-50AC Type Portable Hand Held Tube End Deburring Pipe Chamfering Machine

Main Technical Parameters Sheet

Brief Introduction on Tube End Deburring Pipe Chamfering Machine

SLS EF-50AC Type Portable Hand Held Tube End Deburring Pipe Chamfering Machine Equipment a Kind of Semi-Automatic Single Head Machine with Manual Loading, Automatic Mechanical Chamfering and Automatic Clamping Driven By Pneumatic. Chamfering Work Can Be Expanded As Three Sides, Two Sides or Single Side Chamfering, Bore a Hole or Thickness Reducing. Chamfering Process Can Be Finished At One Time In Fast Speed and Accurate Chamfering Requirement. Sometimes Chamfering Is Defined As a Form of Bevel, and It Is Usually Processed At a 30,45 or 60 Degree Angle Between Two Adjacent Right-Angle Faces. Clamp Device and Knife Holder Are Precisely Designed for Ensure The Center Line Between Work-Piece and Knife Holder At The Same Level. Chamfering Length Can Be Adjusted Based on Specific Requirement.Choose From Semi-Automatic or Full Automatic with Auto Loading Tube Chamfering Machine to Best Meet Your Level of Production.

Features on Tube End Deburring Pipe Chamfering Machine

● Control Panel Offers Easy Access to Auto and Manual Operating Modes.

● All The Parts Are Made Under Very Strict Quality Control, So The Quality of Machine Is In High Level and The Specification Is Standardized.

● Equipped with Emergency Stop Device.

● A Circular Tube Modifies An Interior Angle, An External Angle and Flat Plane At One Time with Fastness and Precision.

● Automatic and Manual Working Mode Which Are Convenient for Adjusting The Machine, Mold and Chamfering Knife.

● Material Available: Carbon Steel, Stainless Steel, Copper, Aluminum...

● Chamfering Work Is Driven By Mechanical and Clamping Work Driven By Pneumatic.

● Clamp Device and Knife Holder Are Precisely Designed for Ensure The Center Line Between Workpiece and Knife Holder At The Same Level.

● Dual Feed Chamfer System:

First Speed------Fast Forward Movement Nearly to Tube End to Save The Time.

Second Speed---Infinitely Variable Forward Adjustable Chamfering Speed to Get Smooth Finish.

● The Design of The Tooling Help Customer Easy to Change.

● Foot Pedal Cycle Start.

● Optional: Double Head Can Be Added to The Machine Based on Detailed Chamfering Requirement.

Main Application

Packaging & Shipping

Contact Us